Comprehensive Deployment Across All Mines with Phase II Mobile Equipment Monitoring Expansion

Case Duration:

August 2021 – Present

Client Background:

As a wholly-owned subsidiary of Huaihe Energy Holding Group limited liability company, Huai Mine West Mine Investment Management Co., Ltd has established three high-standard million-ton capacity mines in Ordos, Inner Mongolia: Bojianghaizi Coal Mine、Tangjiahui Coal Mine、Selian No.2 Coal Mine. Total approved production capacity: 23 million tons.

Client Background

In recent years, Huai Mine West Mine Investment Management Co., Ltd has steadily pursued a development path prioritizing safety, innovation, green initiatives, and ecological harmony, driving successful corporate transformation and upgrading.

Notably, both Tangjiahui Coal Mine and Selian No.2 Coal Mine have been consecutively honored with the "China Coal Industry Ultra-Safe and High-Efficiency Mine" title for two years running, a testament to their operational excellence and commitment to sustainable mining practices.

Client Requirements & Solutions

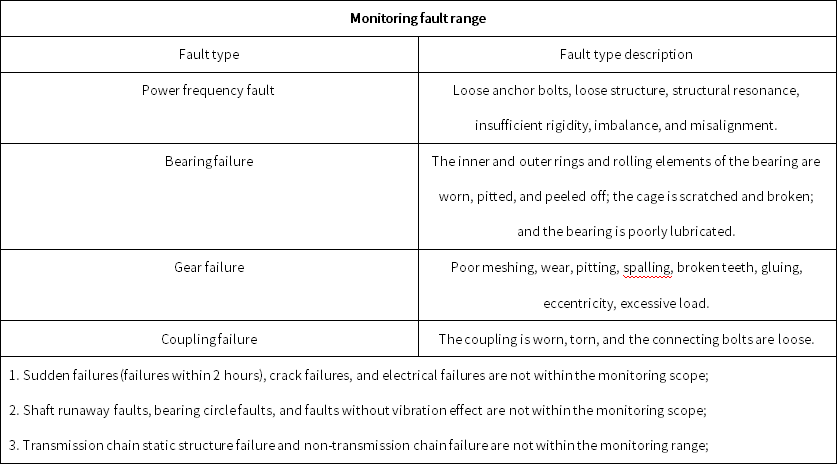

Real-Time Monitoring of Complex Equipment Status:

Given the customer's production characteristics—extended process flows, diverse equipment types, complex machinery structures, and challenging operating environments—RONDS implemented an online monitoring solution to achieve:

1. Progressive real-time status monitoring for both stationary and mobile equipment across all three mines

2. Comprehensive coverage of critical assets including:

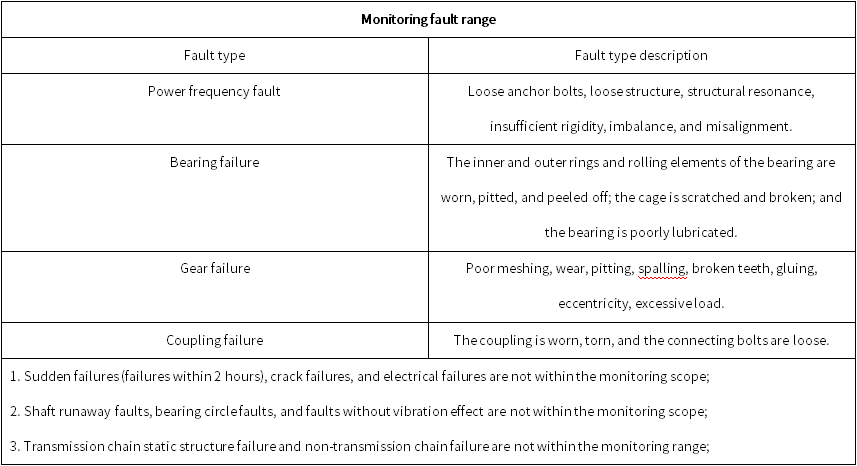

Four major equipment categories

Main haulage conveyor belts

Fully-mechanized mining face scraper conveyors

Transfer machines

Crushers

3. Continuous equipment status data acquisition

4. Complete operational visibility

5. Improvement in equipment operational availability

Life-cycle Management System Implementation:

RONDS integrated online monitoring systems with the mines' existing equipment management platforms to:

1. Establish standardized equipment management protocols

2. Implement core processes including:

Routine inspection management

Overhaul management

Spare parts inventory control

3. Digitalize and streamline maintenance operations

4. Formalize spare parts management workflows

Application Value

Immediate Predictive Maintenance Results:

1. Prevented unplanned shutdowns

2. Eliminated potential safety incidents

3. Safeguarded normal operation

Standardized & Knowledge-Based Management:

Achieved through system integration:

1. Real-time equipment visibility

2. Data-driven spare parts optimization

3. Centralized operational analytics

4. Preserved expert diagnostic knowledge

24/7 Monitoring with Collaborative Response:

Established effective coordination mechanism featuring:

1. Continuous equipment guardianship

2. Remote intelligent diagnostics

3. On-site rapid response

4. Enhanced efficiency in equipment management

Success Cases

-

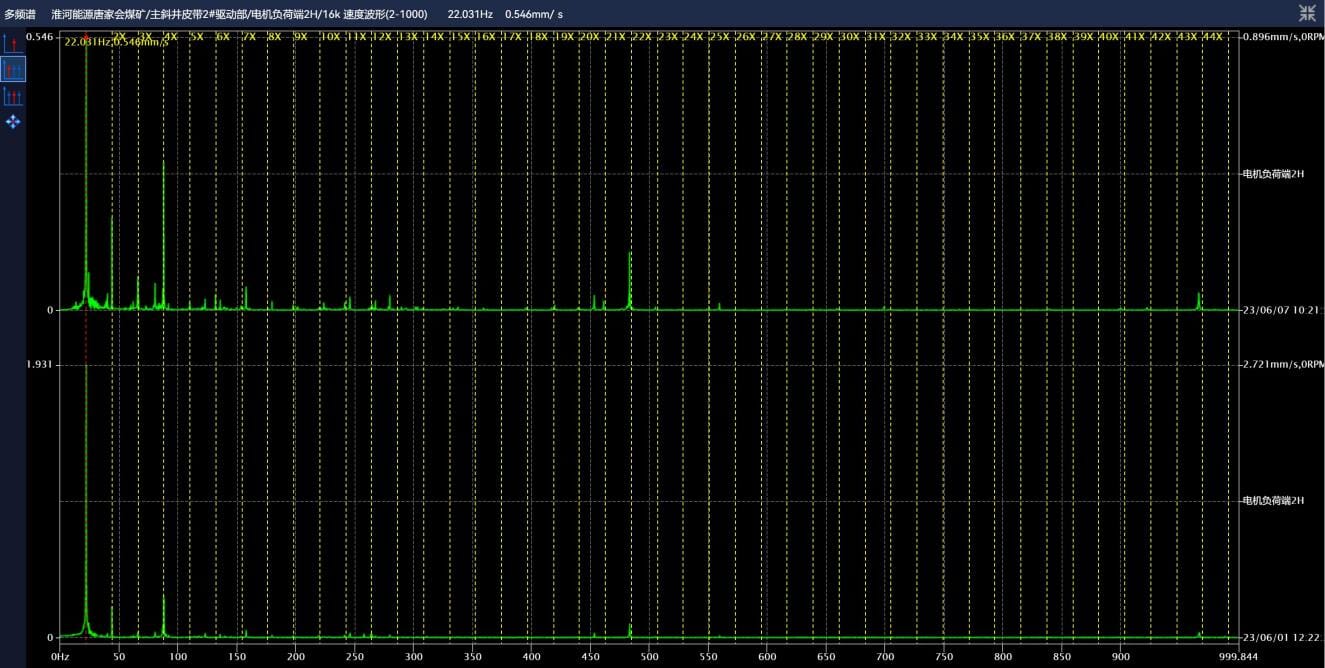

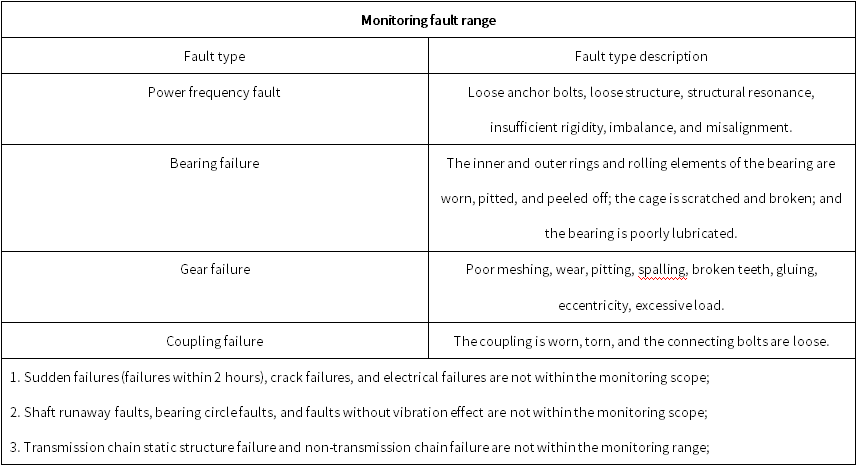

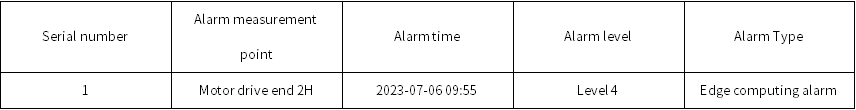

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine Main inclined shaft belt 2# drive unit

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine Main inclined shaft belt 2# drive unitLearn More

-

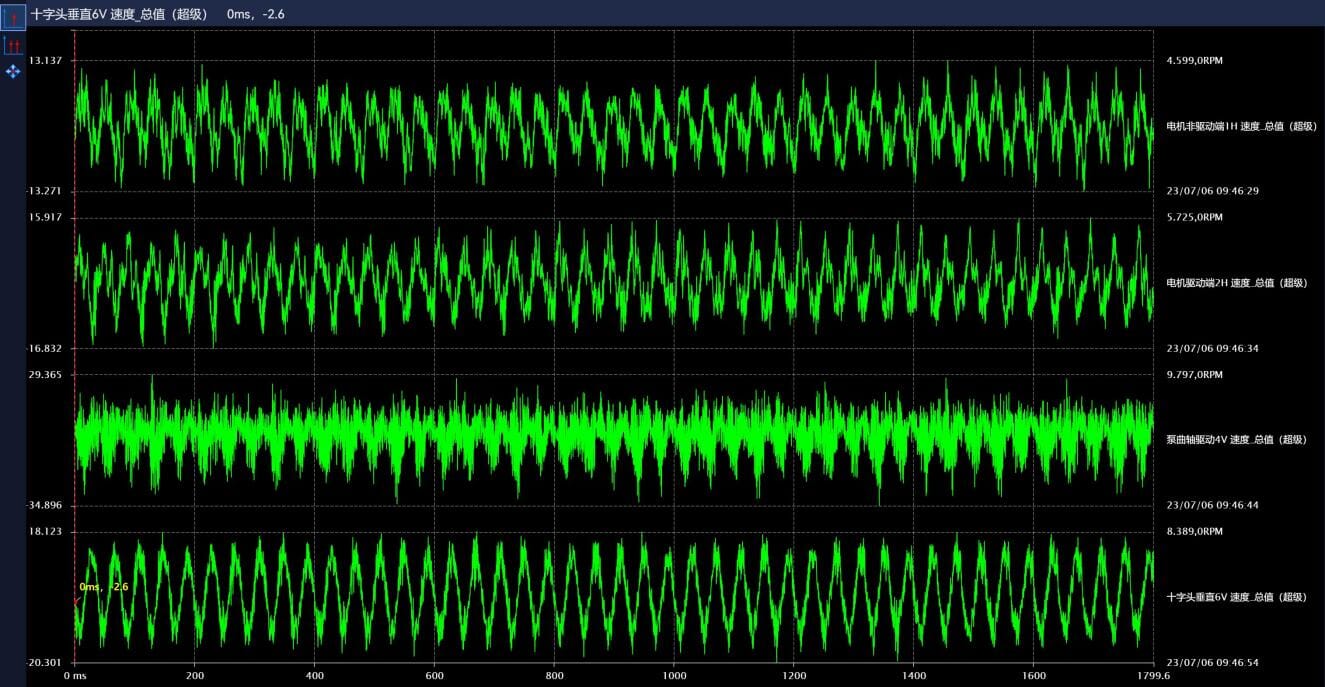

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine 61302 working surface 4# emulsification pump

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine 61302 working surface 4# emulsification pumpLearn More

-

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine Upper silo belt head crusher

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine Upper silo belt head crusherLearn More

-

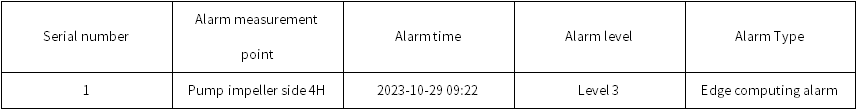

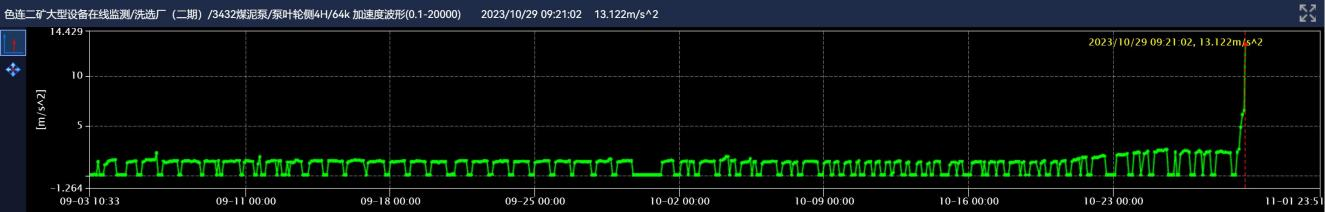

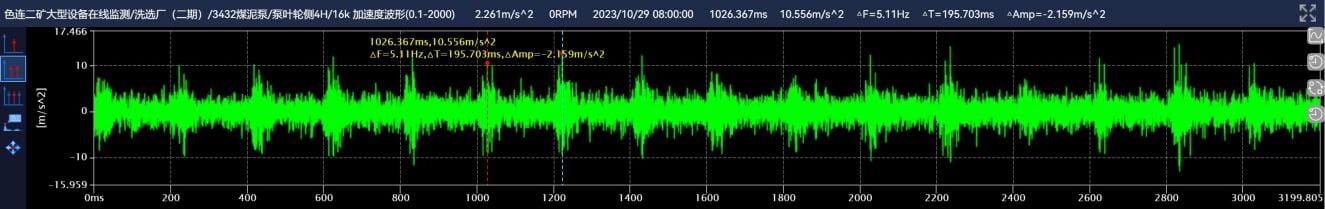

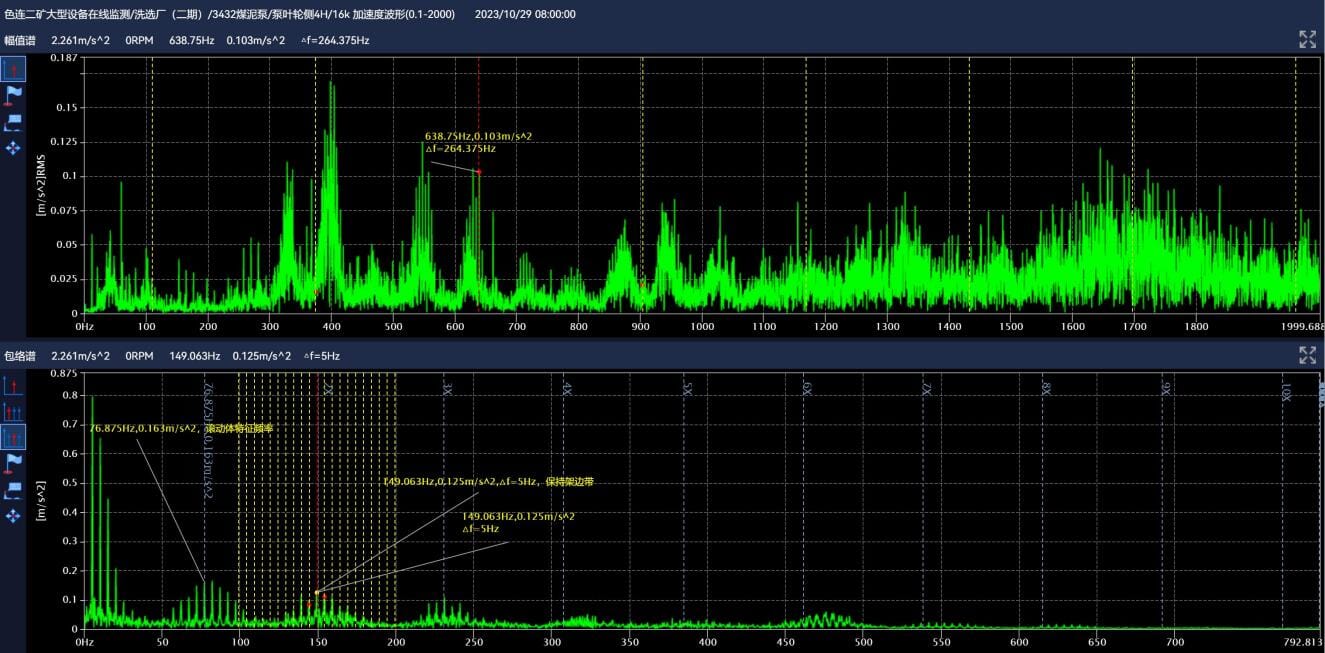

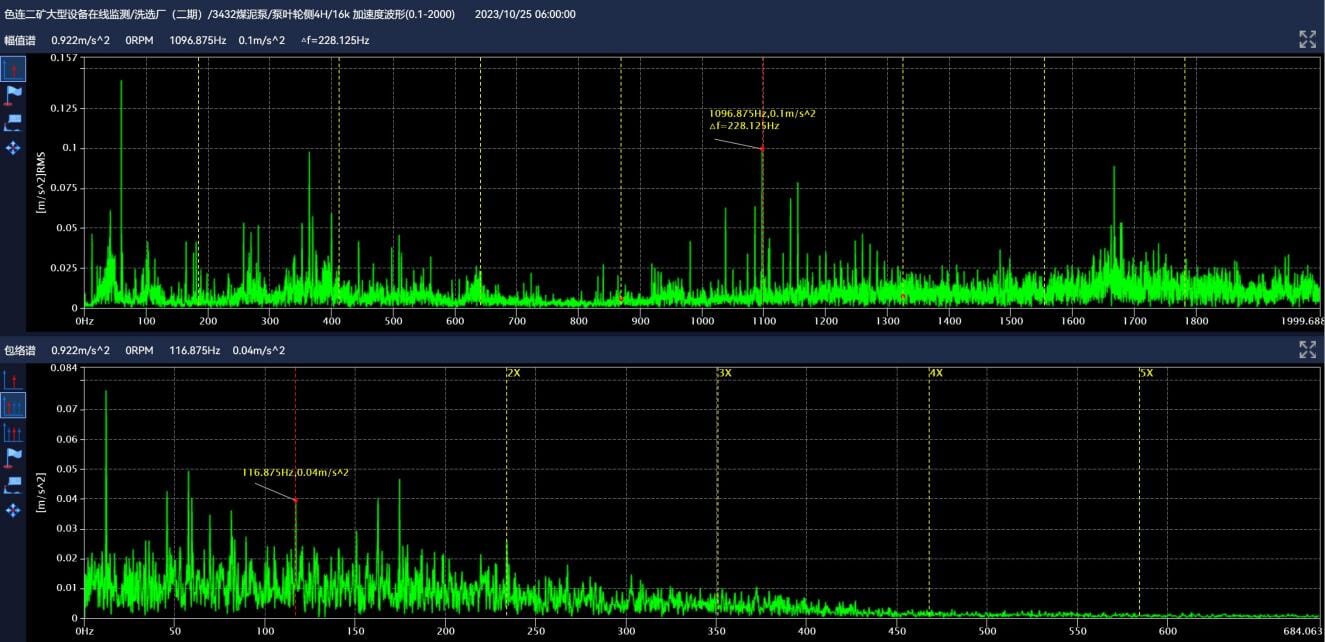

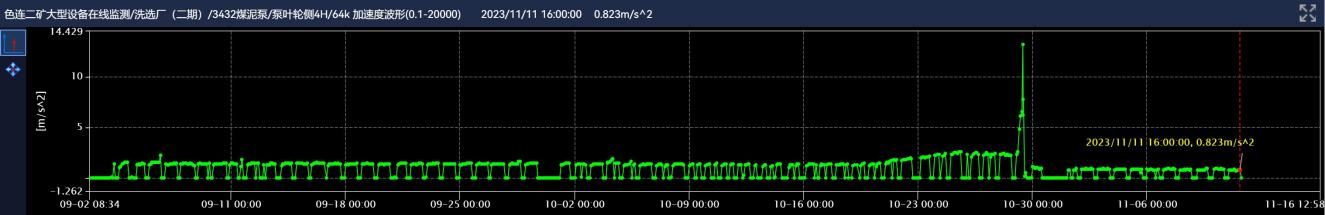

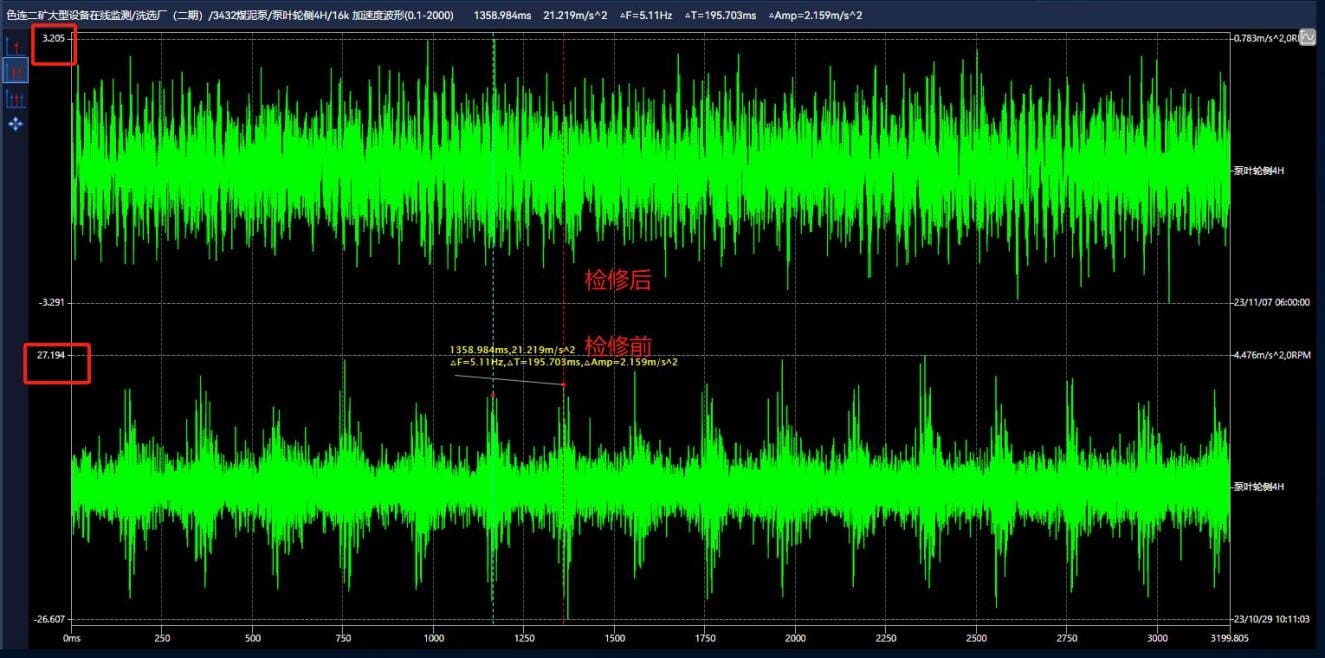

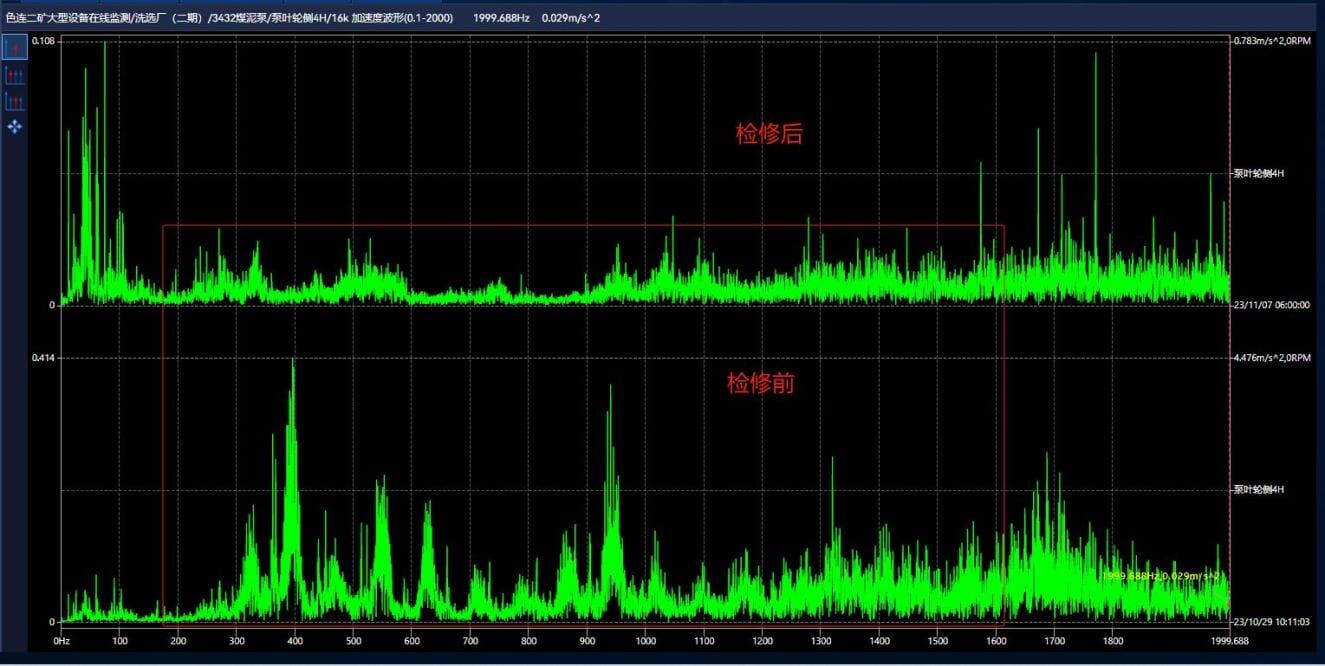

Huaihe Energy Western Coal and Electricity Group Selian No. 2 Coal Mine 3432 Coal Slurry Pump

Huaihe Energy Western Coal and Electricity Group Selian No. 2 Coal Mine 3432 Coal Slurry PumpLearn More

-

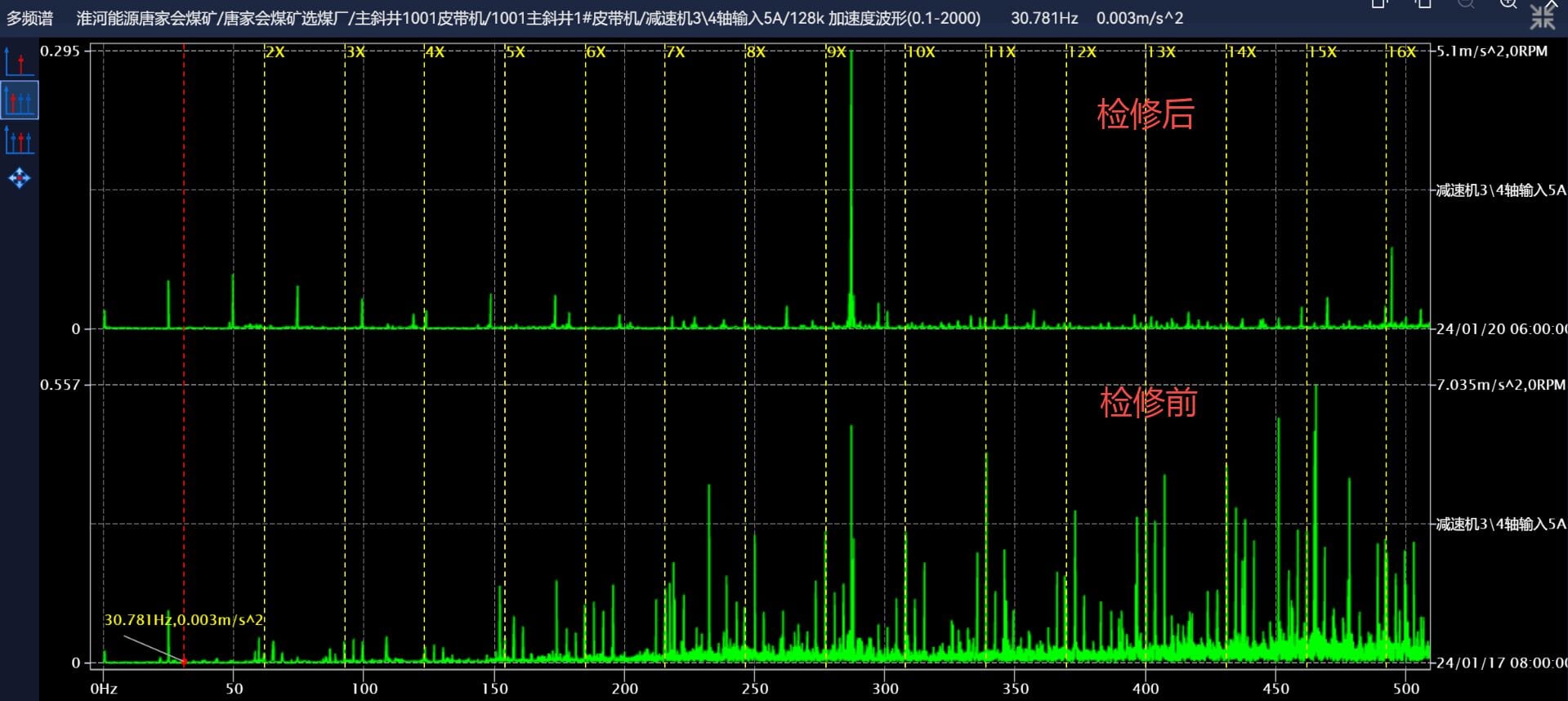

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine 1001 Main Inclined Shaft 1# Belt Conveyor

Huaihe Energy Western Coal and Electricity Group Tangjiahui Coal Mine 1001 Main Inclined Shaft 1# Belt ConveyorLearn More

Start Your Journey to Intelligent Industrial Equipment Maintenance