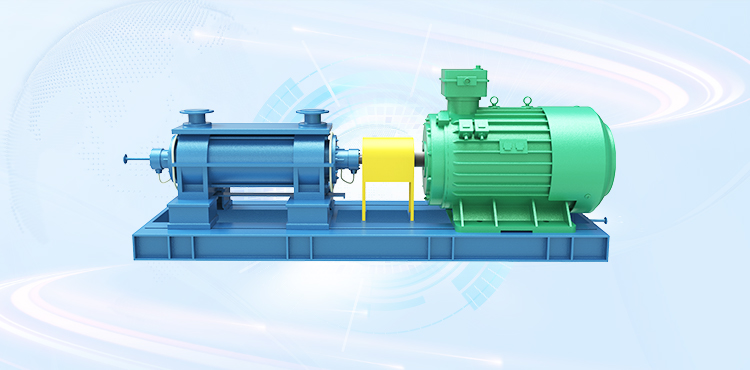

Motors and Pumps

In industrial production equipment, pumps are an important component and undertake important work. Since they often have no spare parts, once a failure occurs, it will greatly affect the operation of subsequent equipment. In serious cases, it will lead to production interruptions and accident risks. Routine maintenance of pump equipment is carried out when there is abnormal operation or equipment failure, and manual inspections are used, relying on human experience to judge equipment failures. They are often in a passive maintenance state, which also brings serious safety hazards to production. Ronds's intelligent monitoring solution for pumps can monitor the operating status of pumps in real time, discover potential safety hazards, issue fault warnings in advance, provide enterprises with scientific inspection and maintenance suggestions, improve pump operation efficiency, reduce production costs, and ensure enterprise safety production.

Monitoring Challenges

-

Difficulty in Inspection

The number of machine pumps is huge, the inspection task is heavy, difficult and inefficient.

-

Single Data Collector

The common solutions in the market only measure vibration temperature, without correlating the working conditions and process quantity data. The data is single and has low accuracy.

-

Lack of Intelligence

Common wireless sensors on the market lack edge algorithms, are unable to perform data preprocessing and anomaly identification on the hardware side, and have poor timeliness in equipment care.

-

Short Battery Life

Common wireless sensors on the market have short battery life and high operation and maintenance costs.

Solution Advantages

-

01Integrated Multi-Parameter Monitoring

It integrates the collection of vibration, temperature, and motor operating conditions to realize self-identification of temperature, speed, and start and stop. It combines operating conditions and process quantity data to realize accurate alarm and accurate statistics of start and stop time.

-

02100+Indicators Edge Computing

It can realize accurate pointing alarm at the collection end and improve early warning efficiency.

-

0320+ Fault Automatic Monitoring

Intelligent alarm and intelligent diagnosis based on a multi-indicator system, covering automatic monitoring of more than 20 faults such as bearings and power frequency.

-

04Full Wireless Deployment

Full wireless access enables wide-range monitoring coverage of key machine and pump equipment.

Start Your Journey to Intelligent Industrial Equipment Maintenance