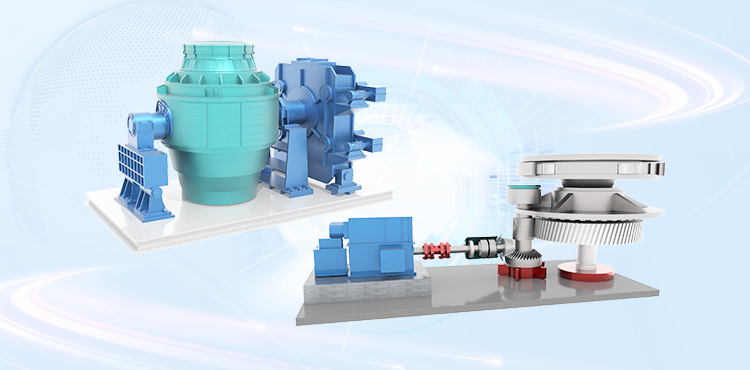

Low Speed and Heavy Load Equipment

Low-speed and heavy-load equipment exists in various industries and plays a key role in industrial production, such as converters, ladle turntables, rough rolling mills, etc. in the metallurgical industry. The operating status of these equipment directly affects production efficiency and safety. However, due to their complex structure, complex working conditions, low-speed operation, and intermittent motion, monitoring is difficult. In view of the difficulty in monitoring low-speed and heavy-load equipment, Ronds uses a variety of latest colletion hardware such as speed, impact, vibration, temperature, displacement, etc. for comprehensive monitoring, effectively ensuring the reliable operation of low-speed and heavy-load equipment.

Monitoring Challenges

-

Difficult to Monitor

Some large equipment has complex structure, low speed and heavy load, great impact, high value and difficult maintenance.

-

Difficulty in Feature Capture

The equipment is not running continuously or the speed is very low, and the vibration waveform cannot periodically reflect the fault characteristics.

-

High Difficulty in Monitoring

Some faults occur at higher frequencies, and traditional vibration sensors cannot capture the corresponding frequencies.

Solution Advantages

-

01Integrated Multi-Parameter Monitoring

The industry-leading sensor integrates shock, vibration and temperature data collector, and the monitoring effect is more outstanding.

-

02Motor Working Condition Linkage

When used in conjunction with motor operating condition sensors, speed-triggered colletion and associated colletion can be achieved.

-

03Dedicated Shock Analysis

Special impact analysis tool to efficiently analyze the root cause of failure.

-

04Ultra-Long Time Waveform Collection

The ultra-long time waveform collection capability enables precise fault characteristic capture.

-

0524/7 Care

Ronds provides 365*24 hours cloud-based expert support and can provide professional diagnostic services.

Start Your Journey to Intelligent Industrial Equipment Maintenance