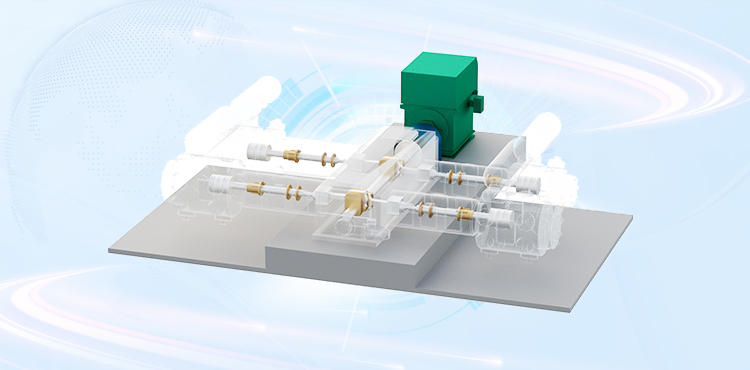

Reciprocating Compressor

Reciprocating compressors are critical equipment in many industries, often operating in complex and harsh environments for extended periods. A single failure can lead to system shutdowns, production interruptions, or even serious accidents that threaten life and property, with potentially enormous direct economic losses and immeasurable indirect losses and social impacts. Ronds’ reciprocating compressor intelligent monitoring solution ensures “safe, stable, long-lasting, full-capacity, and optimal” operation. It provides more scientific maintenance and repair recommendations to increase equipment availability, reduce maintenance costs, and enhance operational efficiency.

Monitoring Challenges

-

Excessive Maintenance Waste

Without guidance on fault diagnosis and maintenance, only scheduled replacements and overhauls can be carried out, leading to a large workload and unnecessary maintenance expenses.

-

Ineffective Inspections

Inspecting vibration and temperature requires significant effort, has low efficiency, and demands highly experienced inspectors, highlighting the urgent need for online monitoring solutions.

-

High Fault Concealment

Equipment failures are often hidden, making them difficult to detect with static inspections and risky to assess during dynamic inspections.

-

High Expertise Requirements

Diagnosing reciprocating compressor failures involves mechanical, electrical, and pneumatic considerations, requiring comprehensive expertise and specialized diagnostic tools.

Solution Advantages

-

01Rapid Fault Detection

By using a three-in-one sensor that collects vibration acceleration, temperature, and shock pulse data (covering the 30k–40kHz range), the system enables early fault detection.

-

02Easy Installation And Maintenance

A patch-style wireless temperature sensor transmits data wirelessly and attaches directly to the valve surface, simplifying both installation and maintenance.

-

03Innovative Technology Application

Leveraging the latest passive wireless temperature monitoring technology to measure both big-end and small-end bearing temperatures without cables. The sensor integrates with the connecting rod, moving with it safely and without risk.

-

04Independent Alarm Per Machine

By analyzing historical data and using algorithms to automatically calculate and adjust alarm thresholds, each reciprocating compressor operates with its own independent alarm system.

-

0524/7 Monitoring

Ronds provides 365×24-hour expert support via the cloud, offering professional diagnostic services.

Start Your Journey to Intelligent Industrial Equipment Maintenance