Case Duration:

August 2020 – Present

Client Background:

As a subsidiary of CHN Energy specializing in coal and coal-to-liquids (CTL) chemical production

Client Background

As a subsidiary of CHN Energy specializing in coal and coal-to-liquids (CTL) chemical production:

1. Coal Operations:

1) 14 active mining sites

2) Primary products: Anthracite, coking coal, thermal coal

3) Approved capacity: 82.4 million tons/year

4) Current production: 60 million tons/year

2. CTL Chemical Operations:

1) World's largest CTL chemical production base

2) Annual output: 11 million tons of: Oil-based chemicals、Polyolefins、Methanol

Client Requirements & Solutions

Integrated Data Platform for Centralized Management

Smart Hardware Deployment & Data Integration:

1. Predictive maintenance systems deployed across:

1) 7 coal mines

2) 3 coal preparation plants

3) CTL subsidiary

4) Olefins No.2 subsidiary

2. Real-time monitoring of various critical assets

3. Early fault detection with precise degradation assessment

Centralized Diagnostic Center:

Unified platform integrating data from all sites

Enabled 24/7 equipment status tracking

Expert Technical Support:

Established RONDS remote O&M center linkage

Provided on-demand technical support

Application Value

All Critical Equipment Under Secure Monitoring:

Online real-time monitoring has been implemented for 400+ critical equipment units across:

1. 7 subordinate mines

2. 3 coal preparation plants

3. Coal-to-Liquids subsidiary

4. Olefins No.2 subsidiary

Ensuring Efficient, Safe and Green Production:

1. Generated 300+ equipment health reports

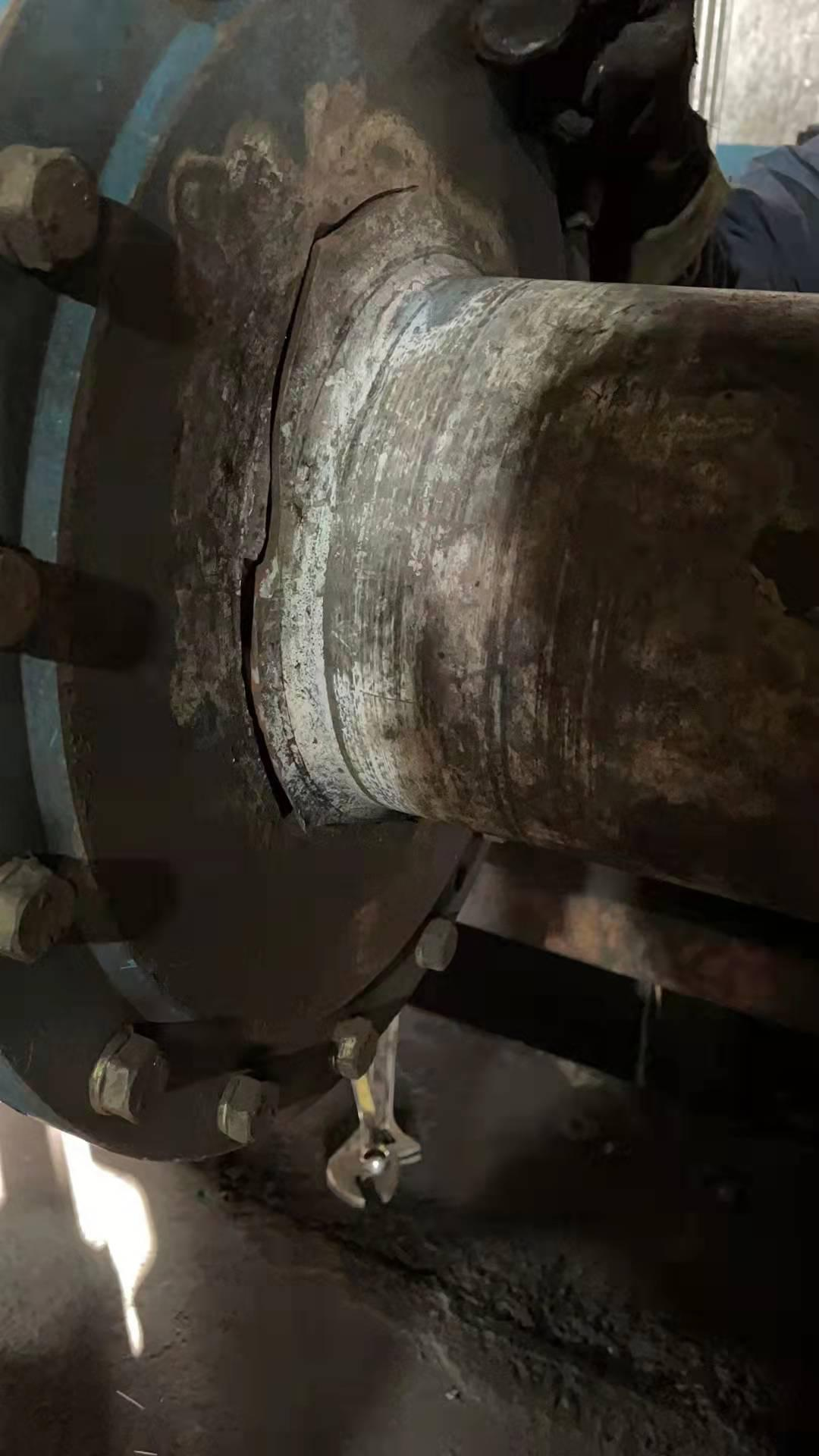

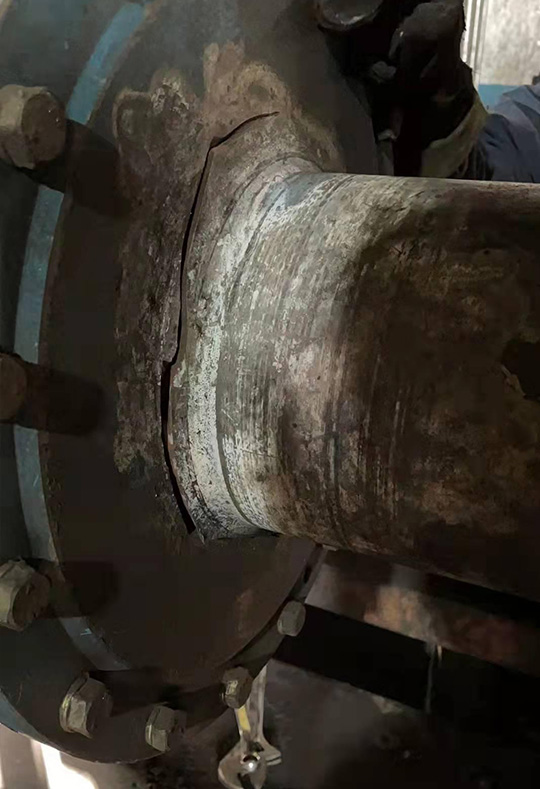

2. Resolved 100+ equipment failure cases through closed-loop management, including:

1) Midnight rapid equipment degradation incidents

2) Predictive maintenance cases

3) Guided repair cases

3. Directly recovered economic losses exceeding CNY 15 million

4. Avoided over 400 hours of unplanned downtime

Eliminating Information Silos to Achieve Centralized and Intelligent Equipment O&M Management:

RONDS has deployed a diagnostic center for the customer that:

1. Aggregates equipment status data from all mines and coal preparation plants

2. Breaks down information silos

3. Establishes a complete equipment O&M management system

4. Realizes centralized and intelligent enterprise equipment O&M management

Success Cases

-

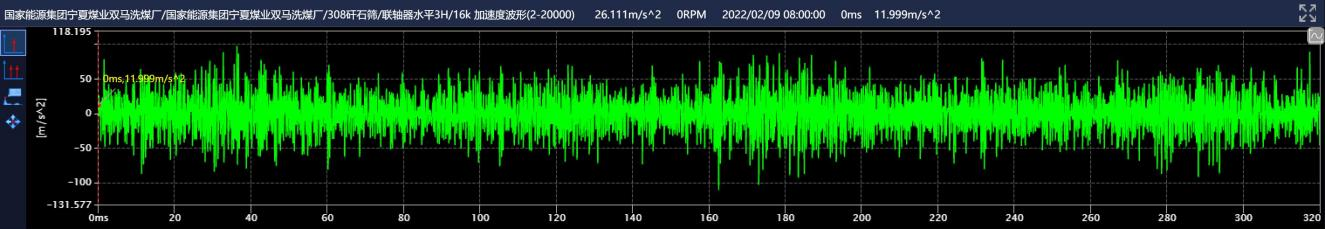

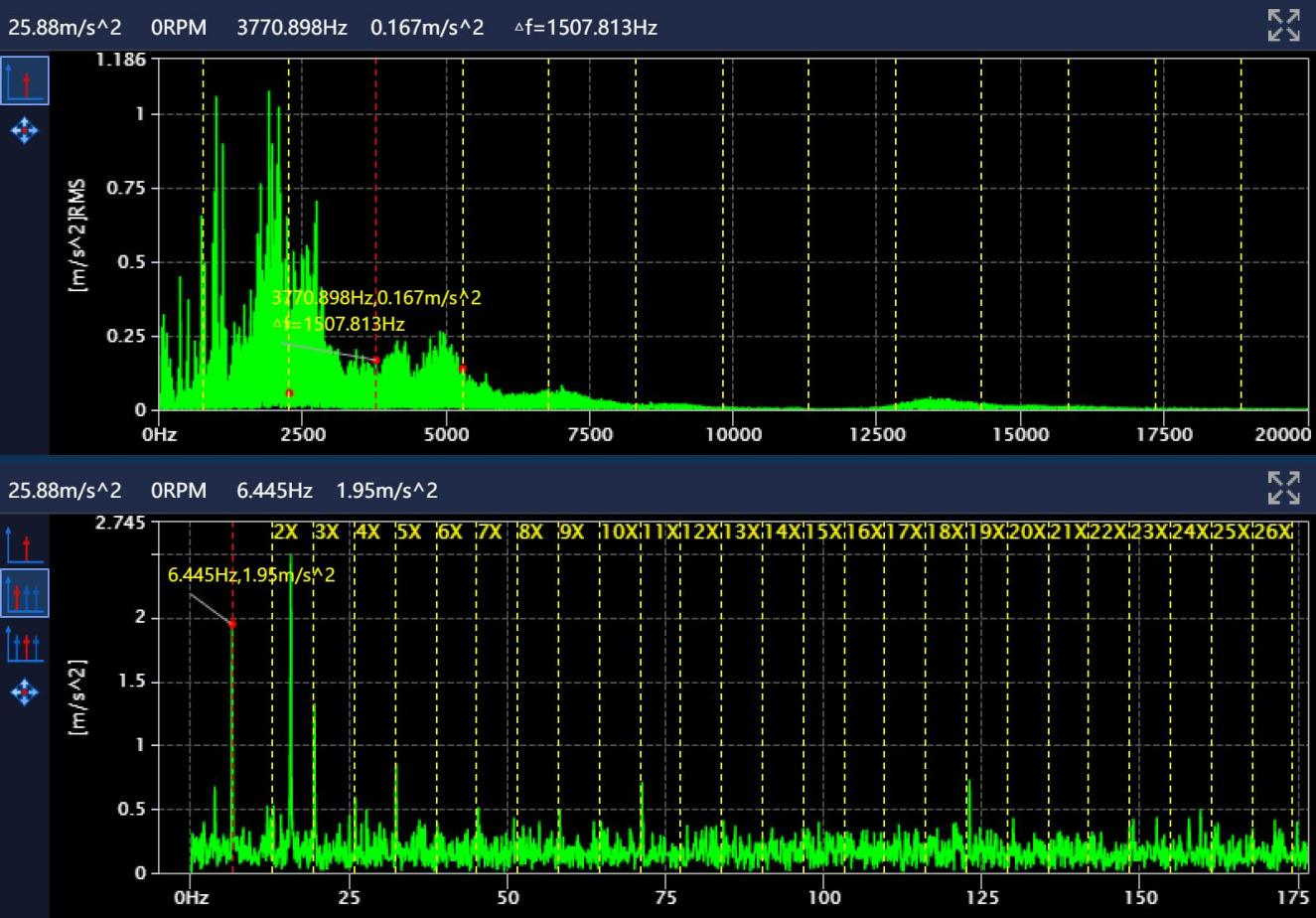

National Energy Group Ningxia Coal Industry Shuangma Coal Washing Plant 308 Gangue Screen

National Energy Group Ningxia Coal Industry Shuangma Coal Washing Plant 308 Gangue ScreenLearn More

-

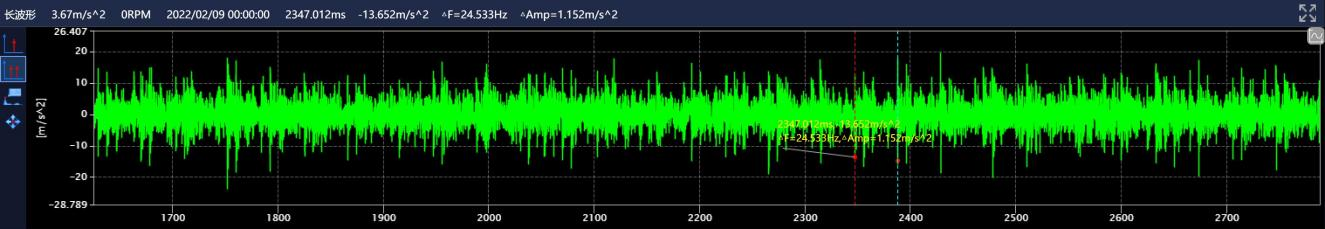

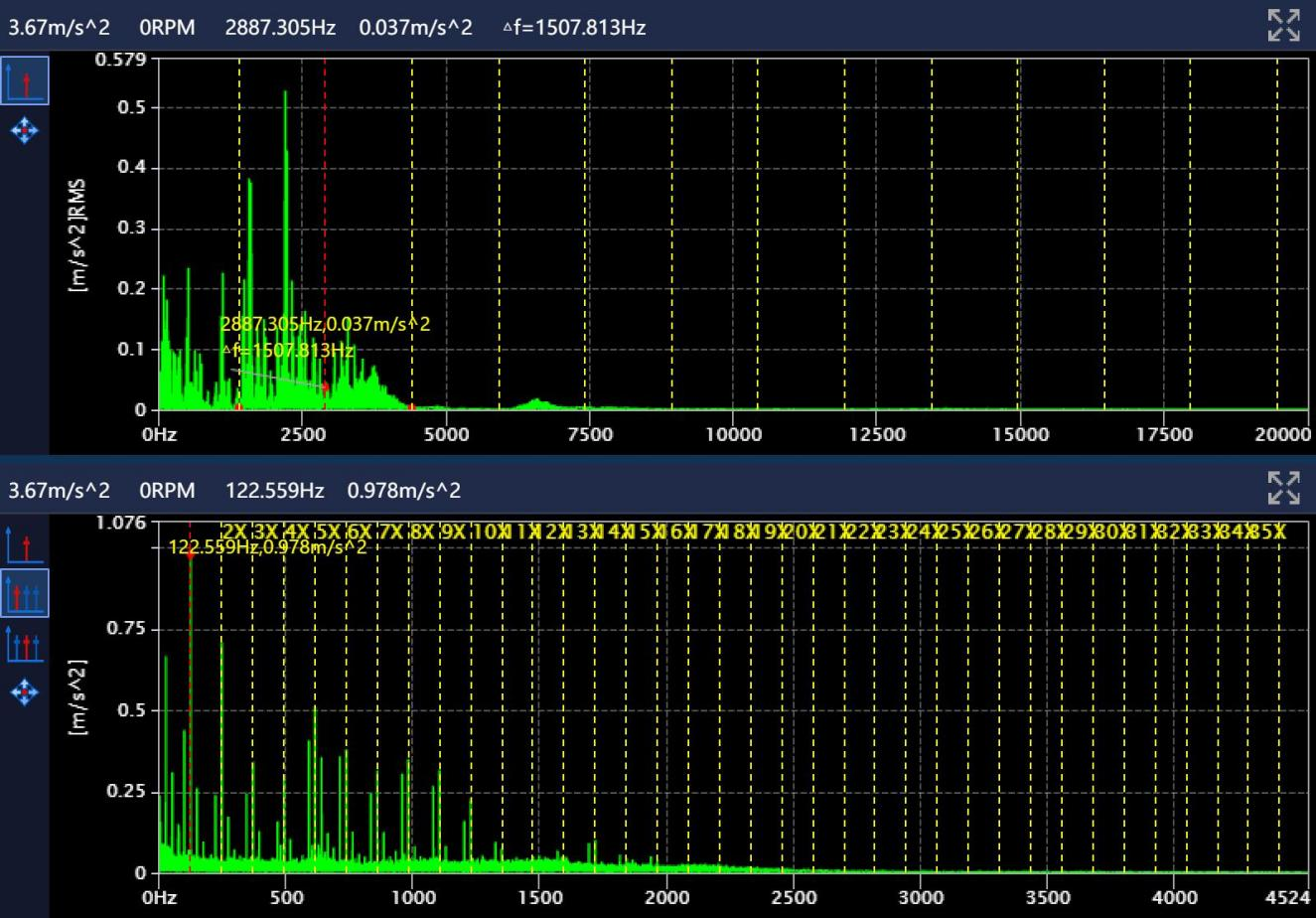

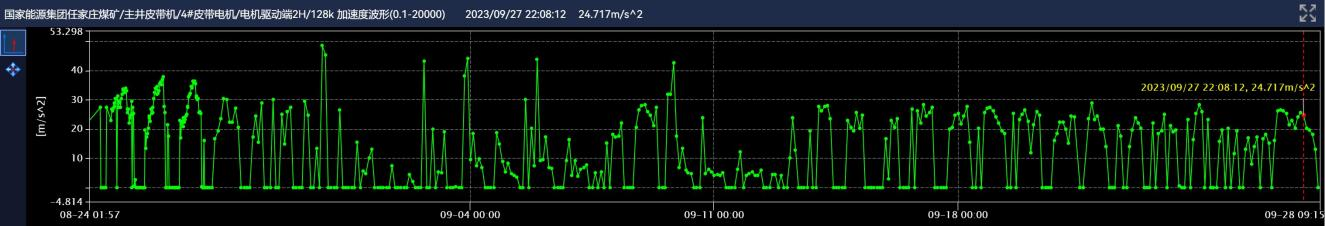

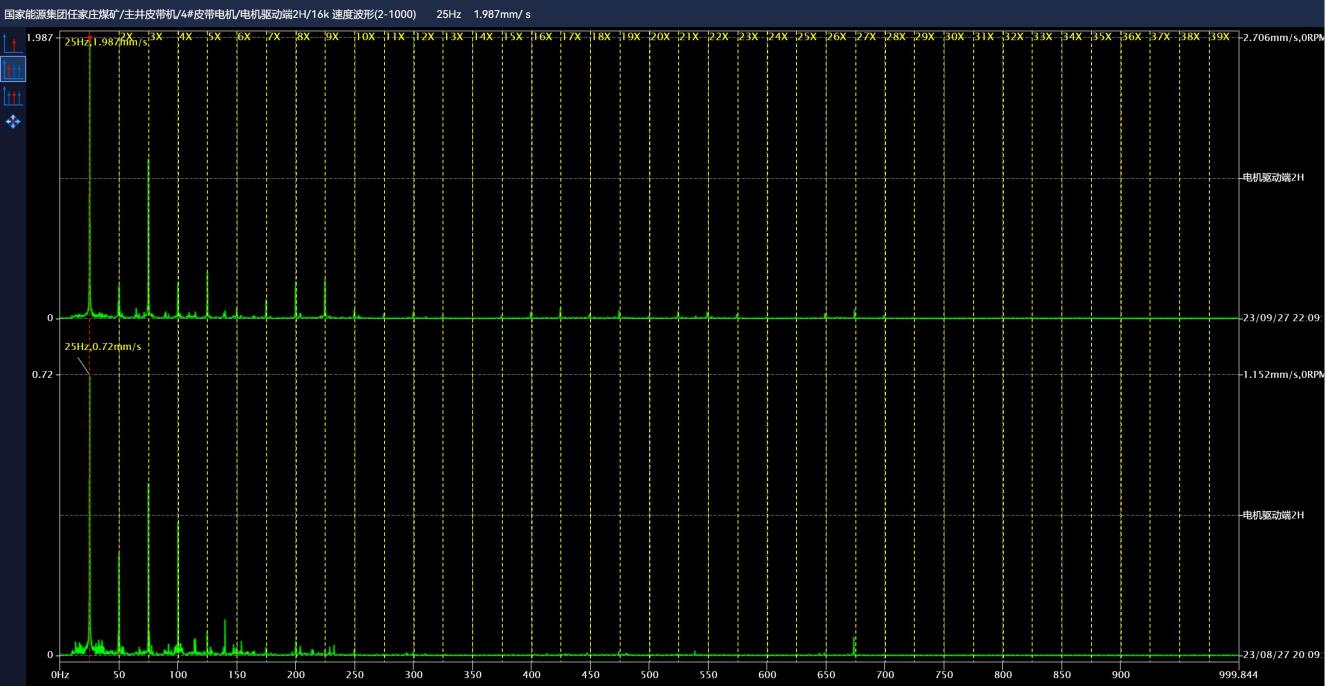

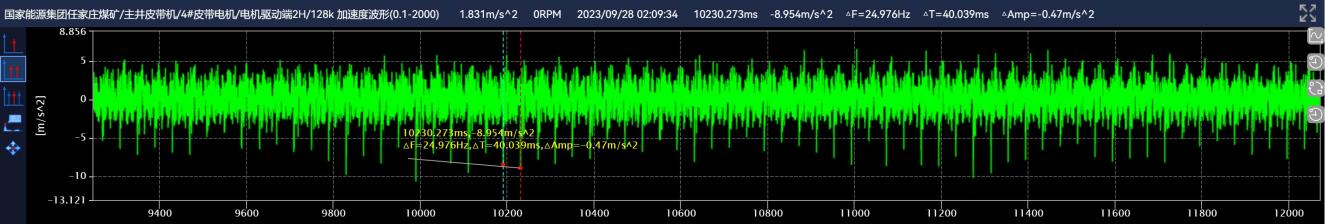

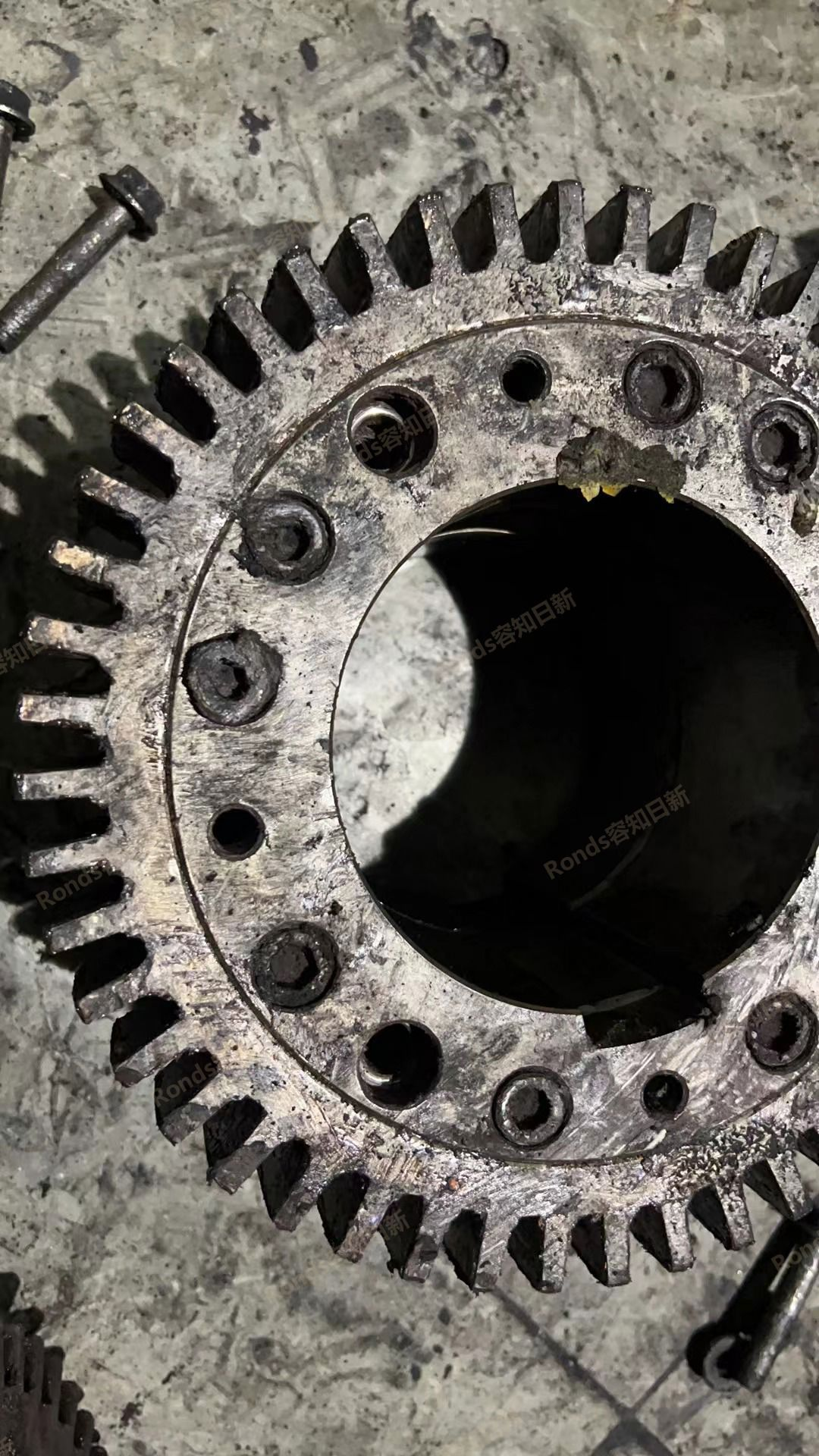

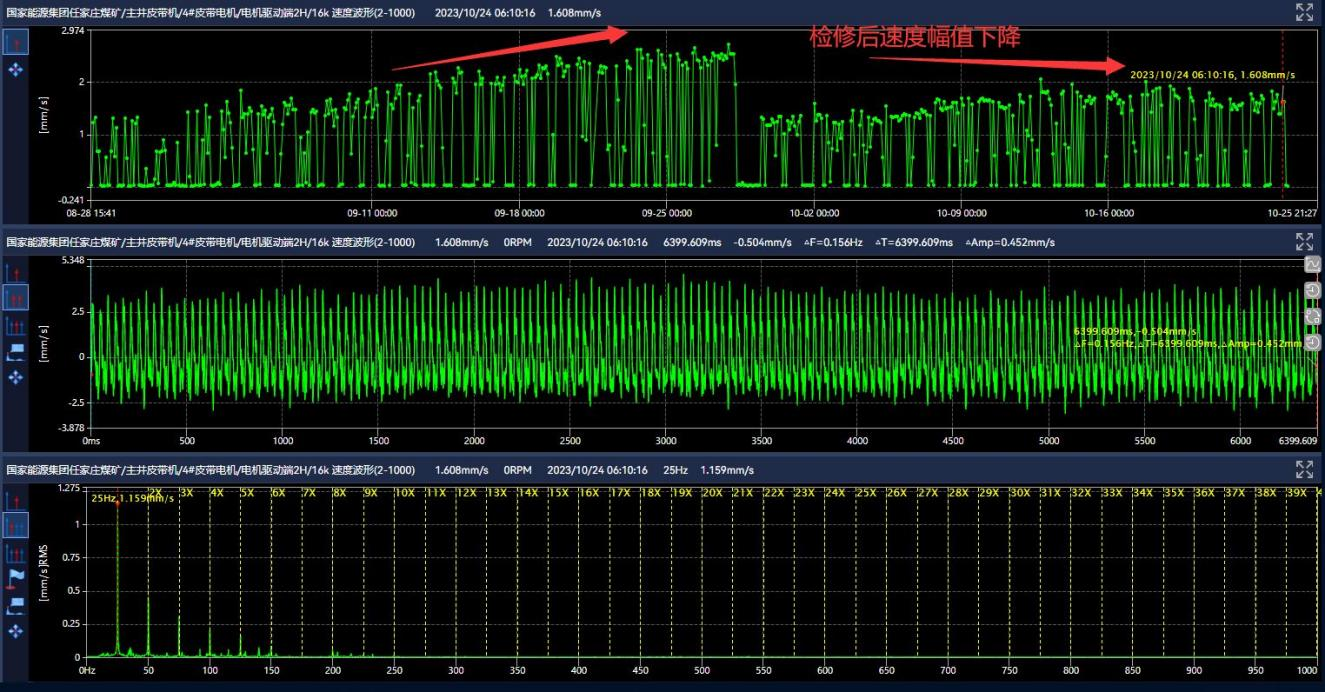

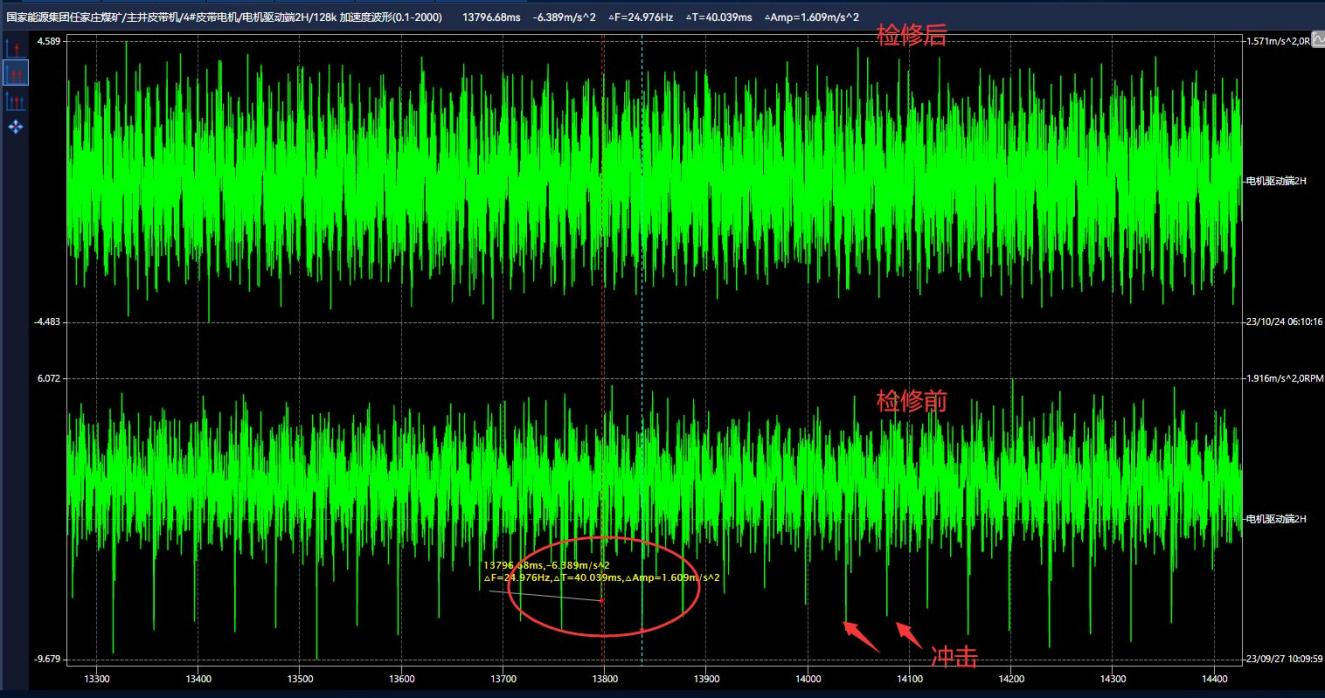

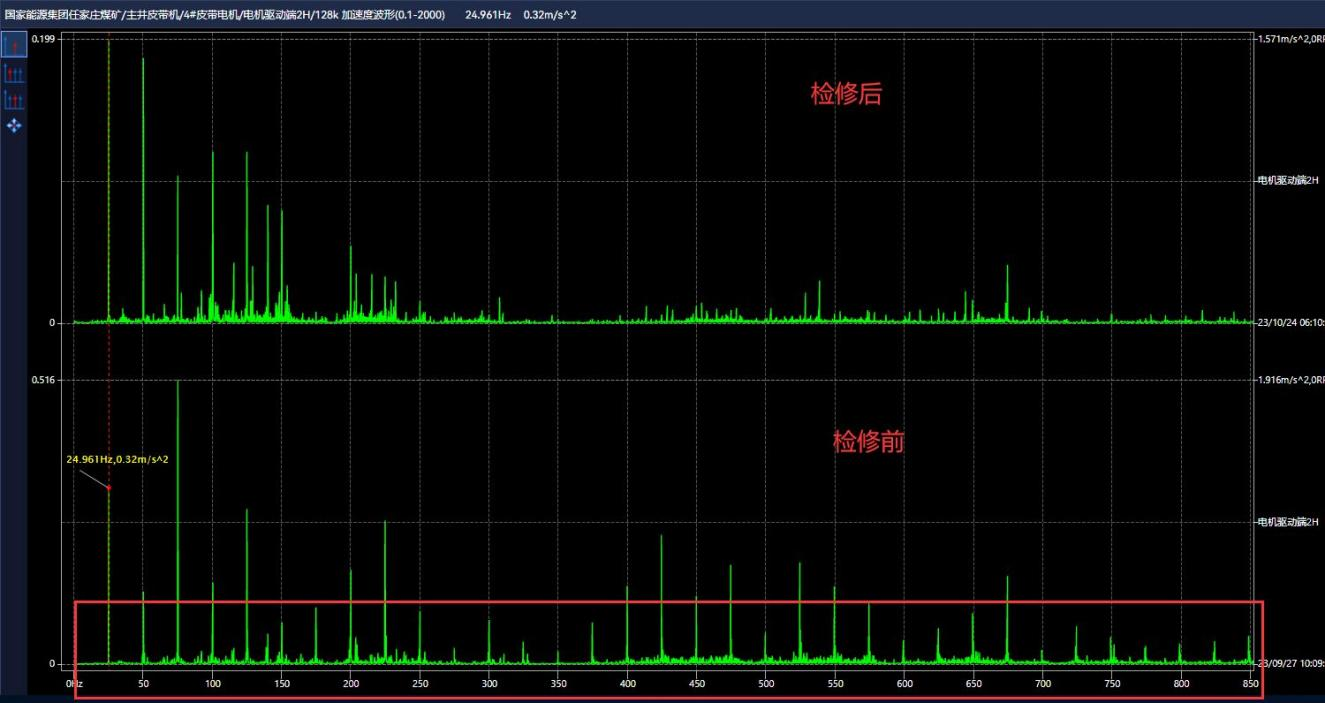

Renjiazhuang Coal Mine of Ningxia Coal Industry of China National Energy Group 4# belt motor

Renjiazhuang Coal Mine of Ningxia Coal Industry of China National Energy Group 4# belt motorLearn More

-

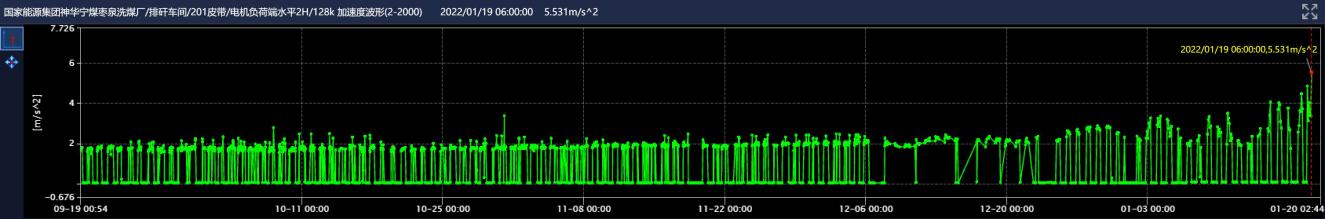

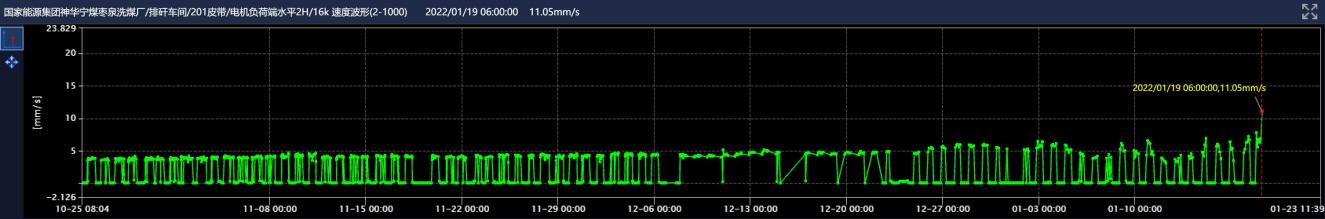

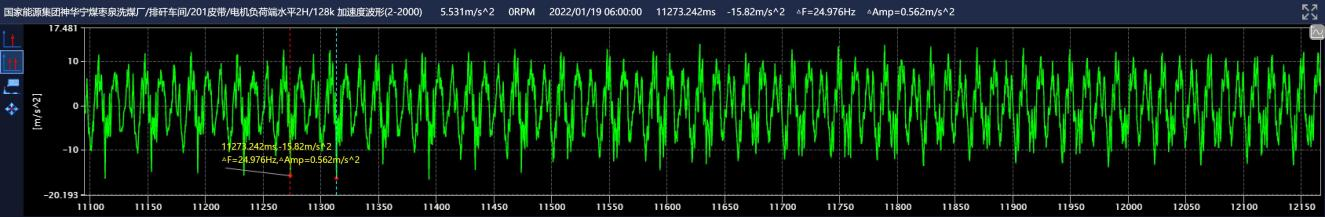

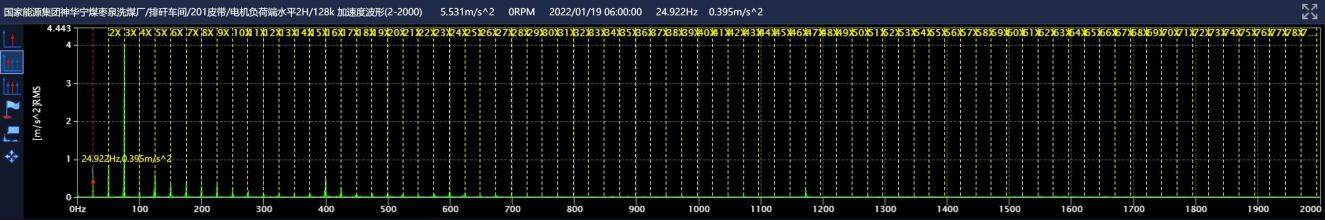

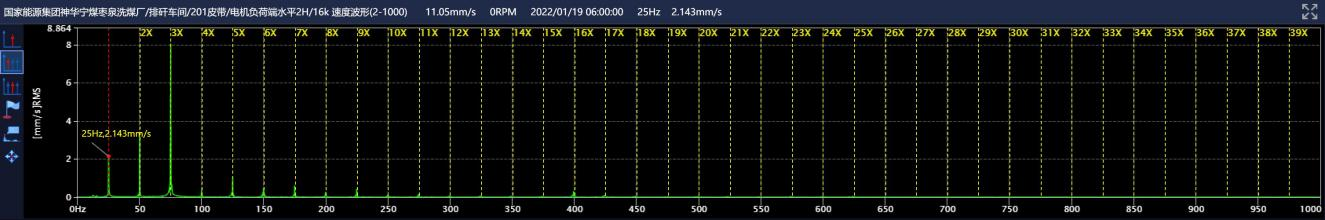

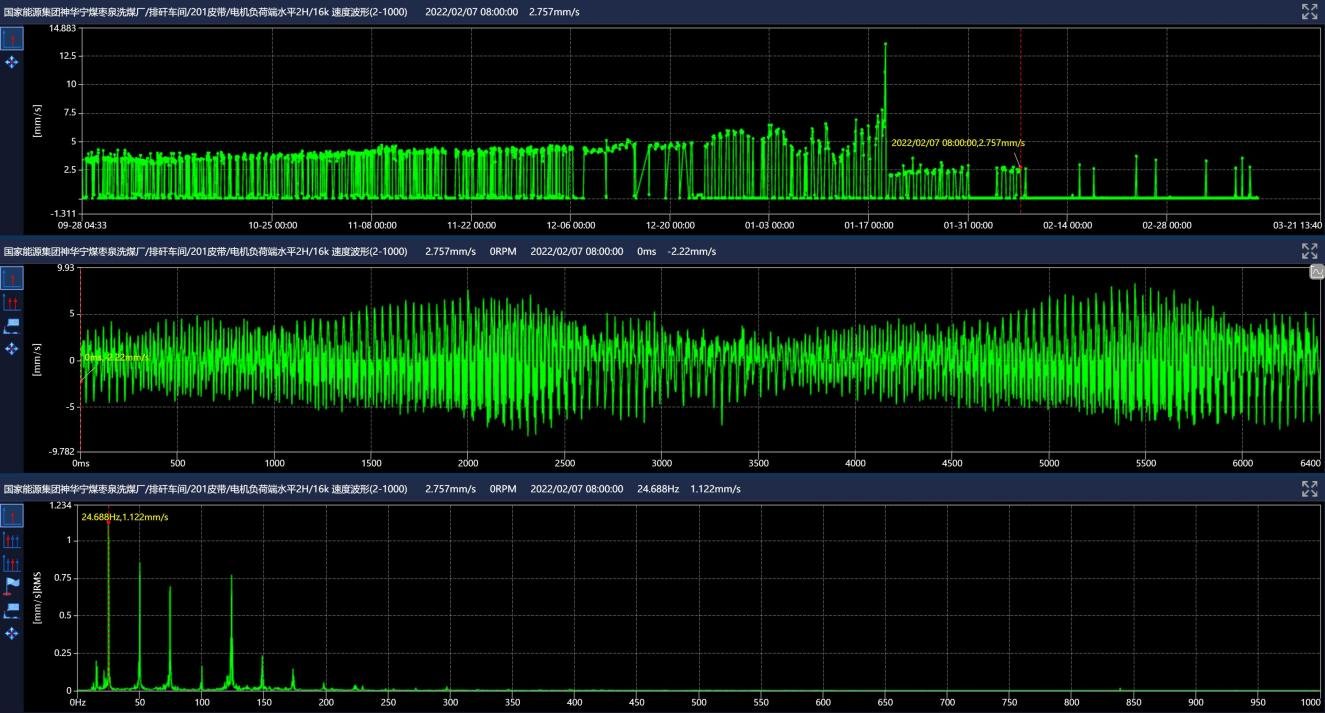

National Energy Group Ningxia Coal Industry Zaoquan Coal Washing Plant 201 belt

National Energy Group Ningxia Coal Industry Zaoquan Coal Washing Plant 201 beltLearn More

Start Your Journey to Intelligent Industrial Equipment Maintenance