Case Duration:

November 2020 – Present (3+ Years)

Client Background:

The Chemical Branch of ZTHC Energy Co., Ltd. operates China's largest coal-to-olefins facility with

Client Background

The Chemical Branch of ZTHC Energy Co., Ltd. operates China's largest coal-to-olefins facility with:

1. Total investment: CNY 60 billion

2. Annual production capacity:

1) 3.6 million tons methanol (intermediate product)

2) 1.37 million tons polyolefins

3. Designation:

1) National coal deep-processing demonstration project

2) Key project of Inner Mongolia Autonomous Region

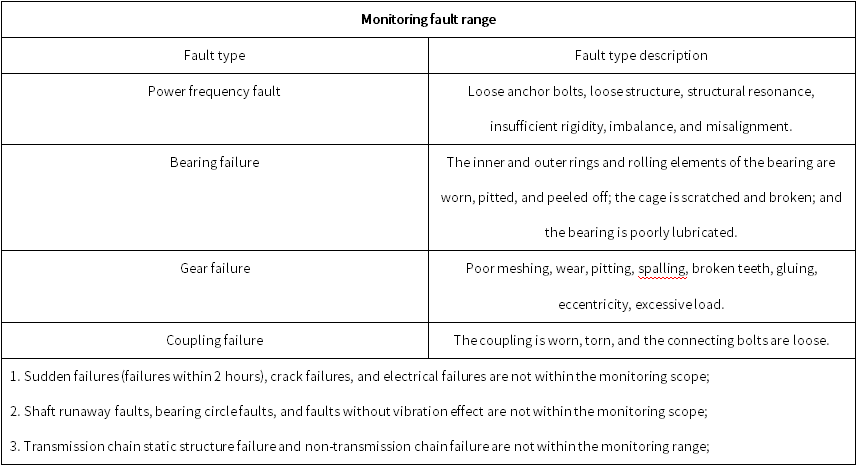

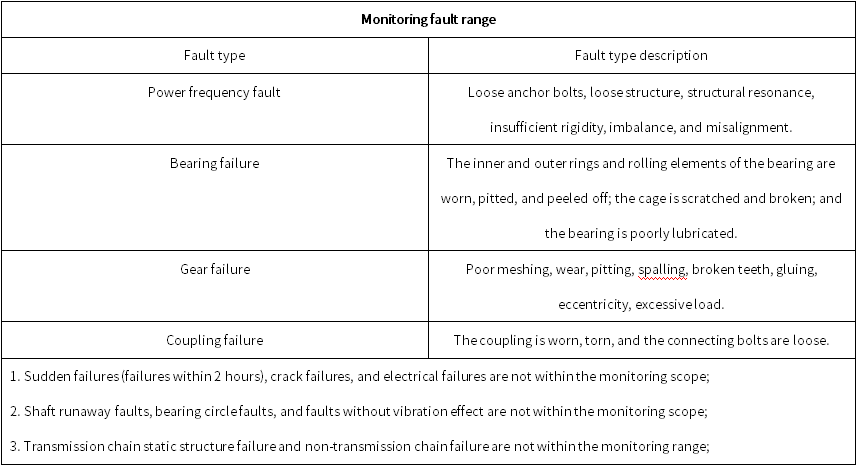

Client Requirements & Solutions

Predictive Maintenance System for Centralized Equipment Management

Comprehensive Predictive Maintenance System:

1. Monitors 340+ critical equipment units across:

1) 19 production units

2) 6 operational departments

2. Covers key assets including:

1) Extruders

2) Compressors

3) Coal mills

4) Pumps & fans

3. Provides:

1) Early anomaly detection

2) Precise fault localization

3) Degradation trend analysis

Plant-wide Centralized Control:

1. Integrated predictive maintenance system with RONDS Remote O&M Center

2. "Edge-Cloud" collaborative monitoring architecture

3. Unified equipment status dashboard

Application Value

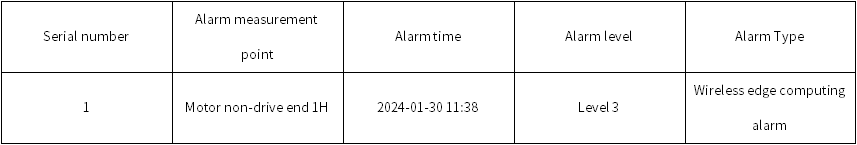

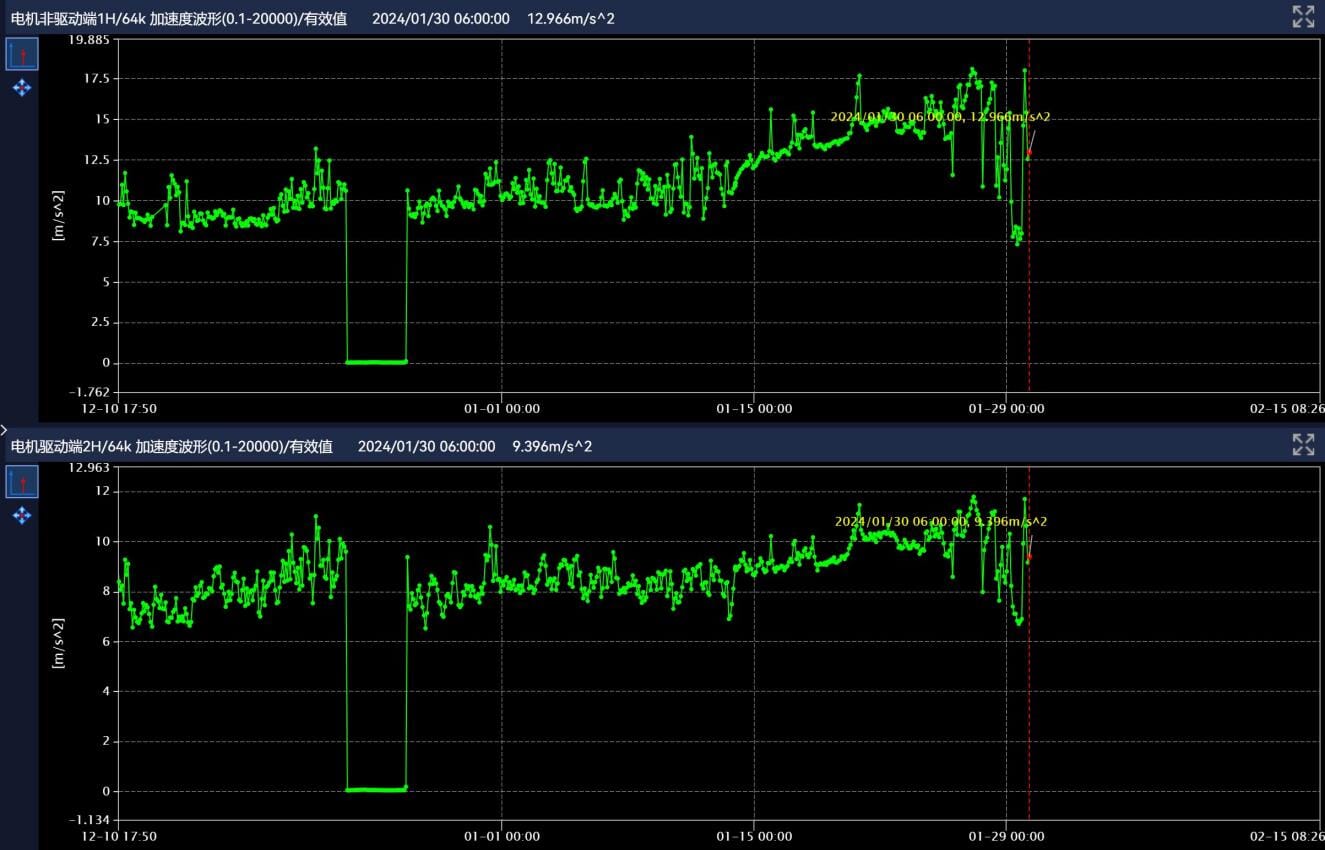

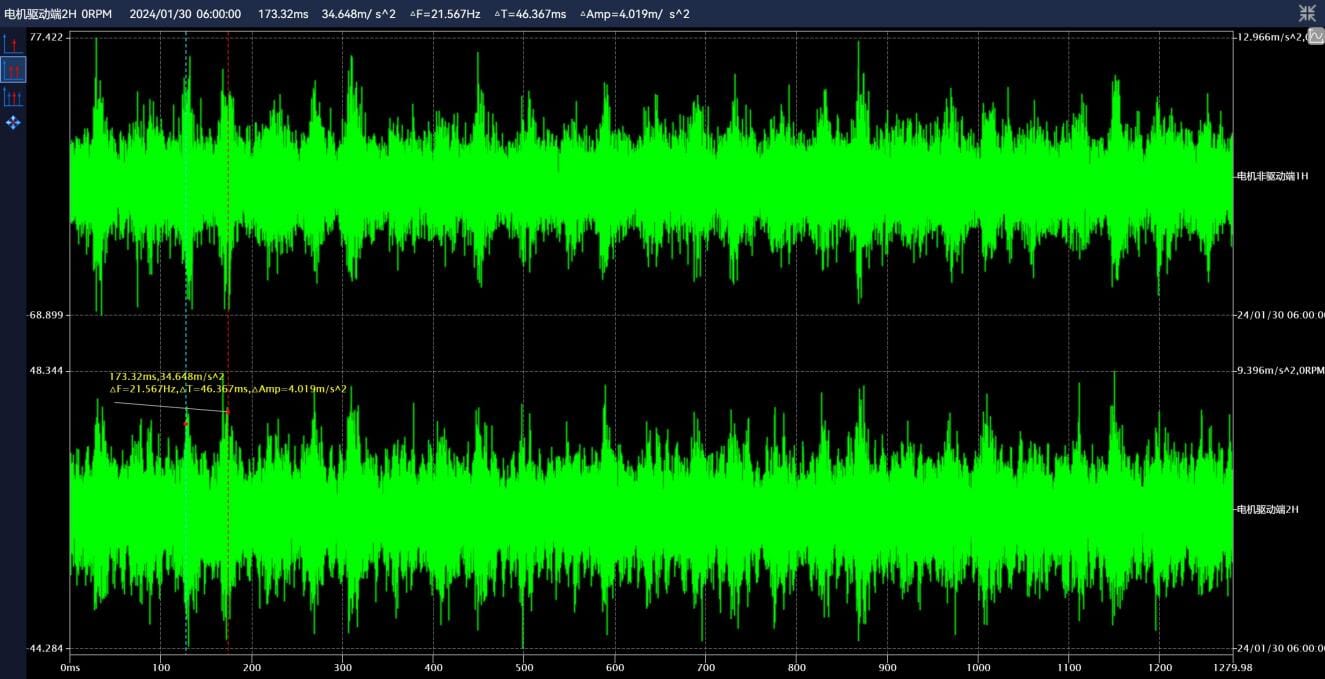

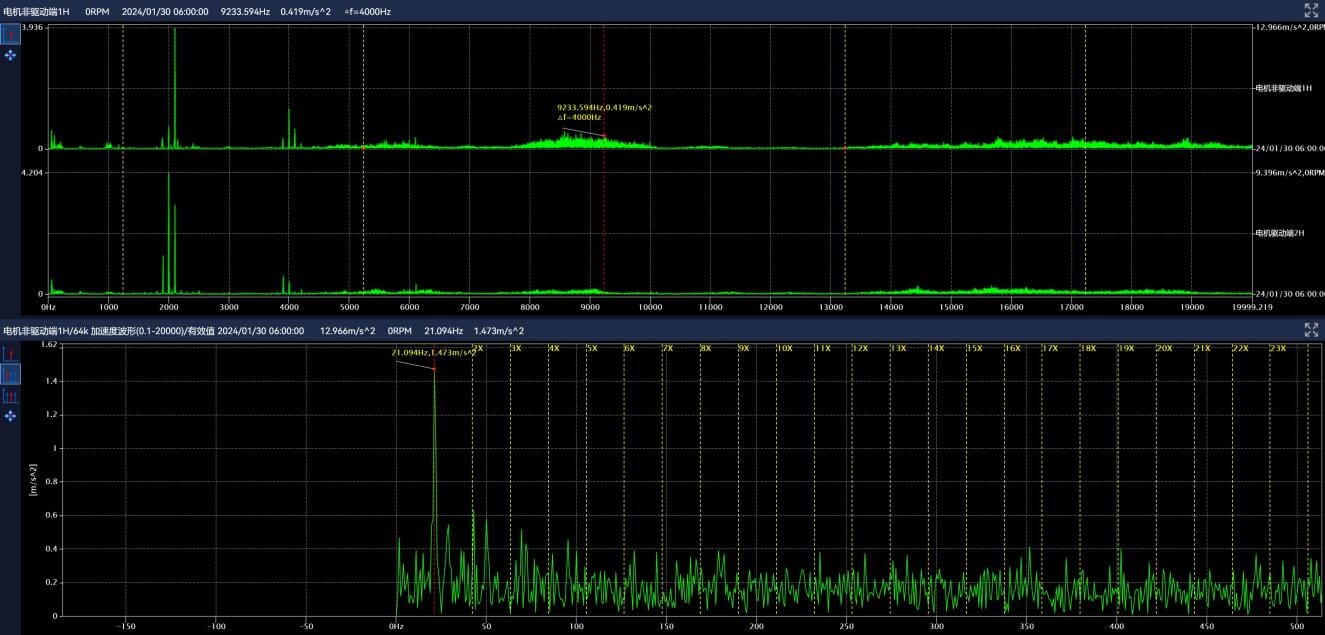

24/7 Equipment Monitoring & Control:

1. 300+ alarms and maintenance recommendations issued

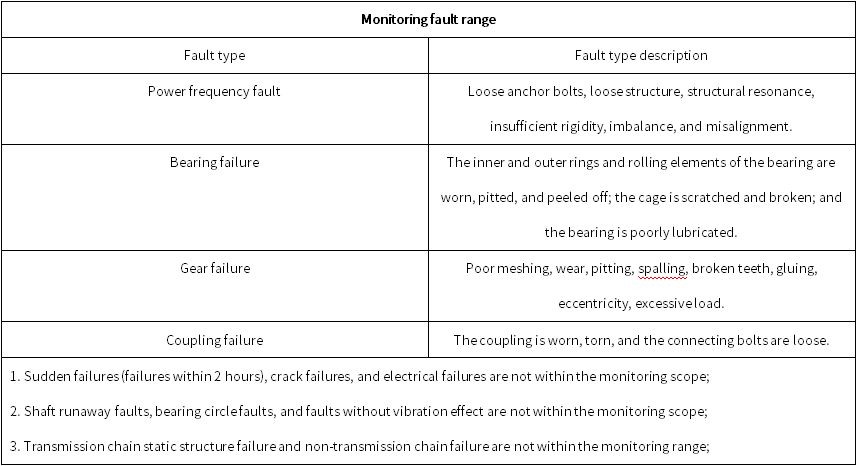

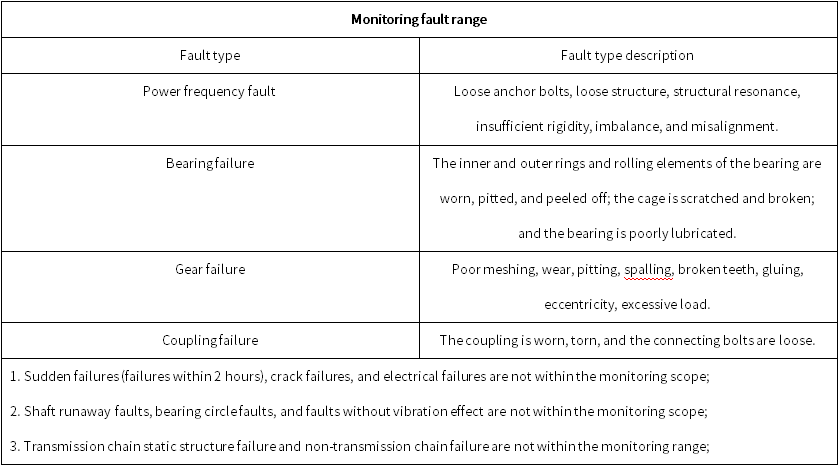

2. Detected failures including:

1) Bearing defects

2) Power frequency abnormalities

3) Component wear alerts

Data-Driven Maintenance Optimization:

1. Monthly equipment health reports for all assets

2. Proactive hazard notifications

3. Data-supported maintenance planning

Standardized & Lean Management:

1. Implemented condition-based maintenance

2. Improved spare parts utilization

3. Reduced maintenance complexity

4. Achieved:

1) fewer over-maintenance cases

2) reduction in maintenance backlog

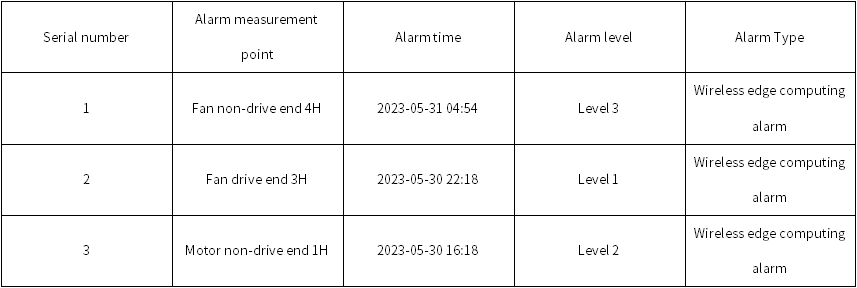

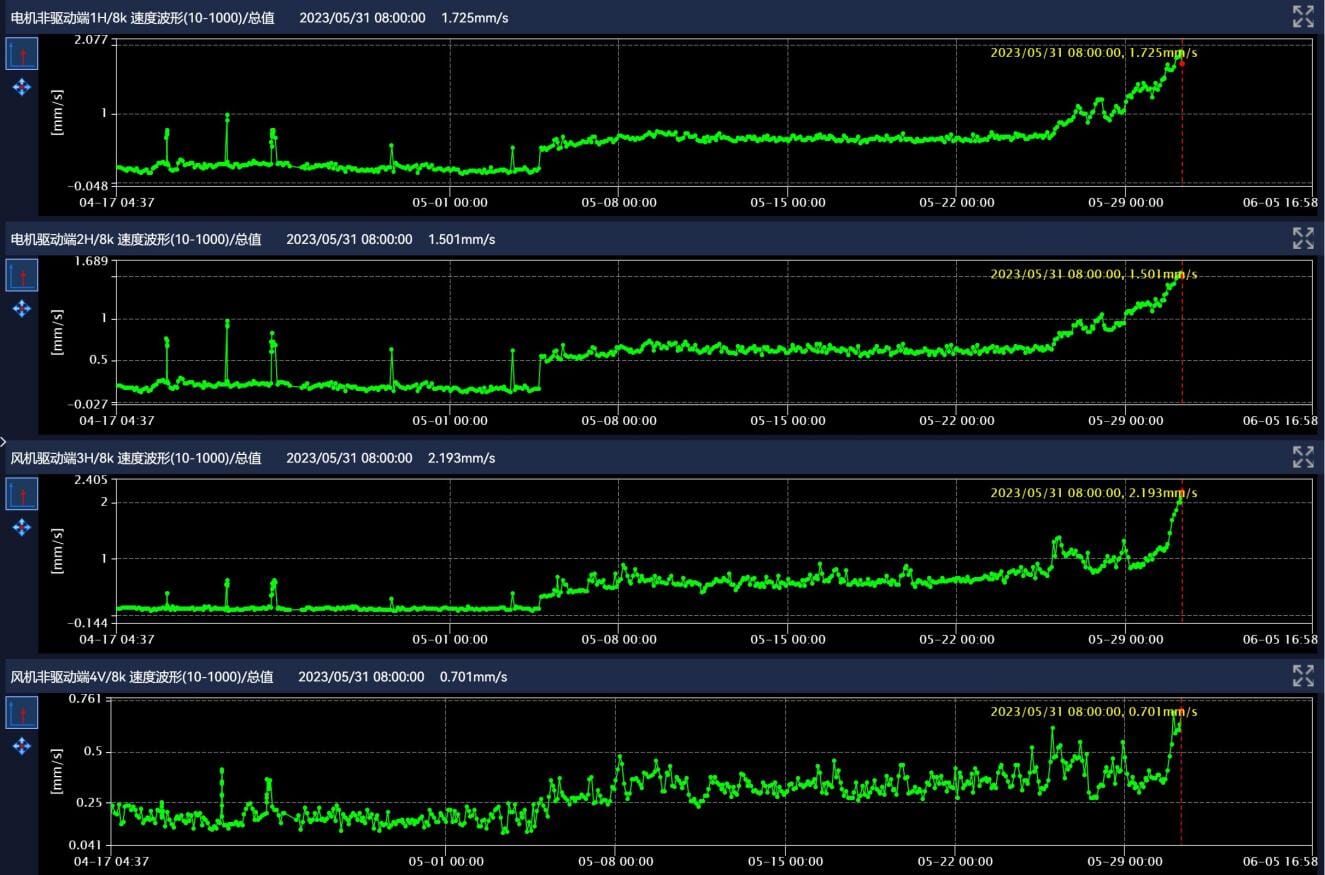

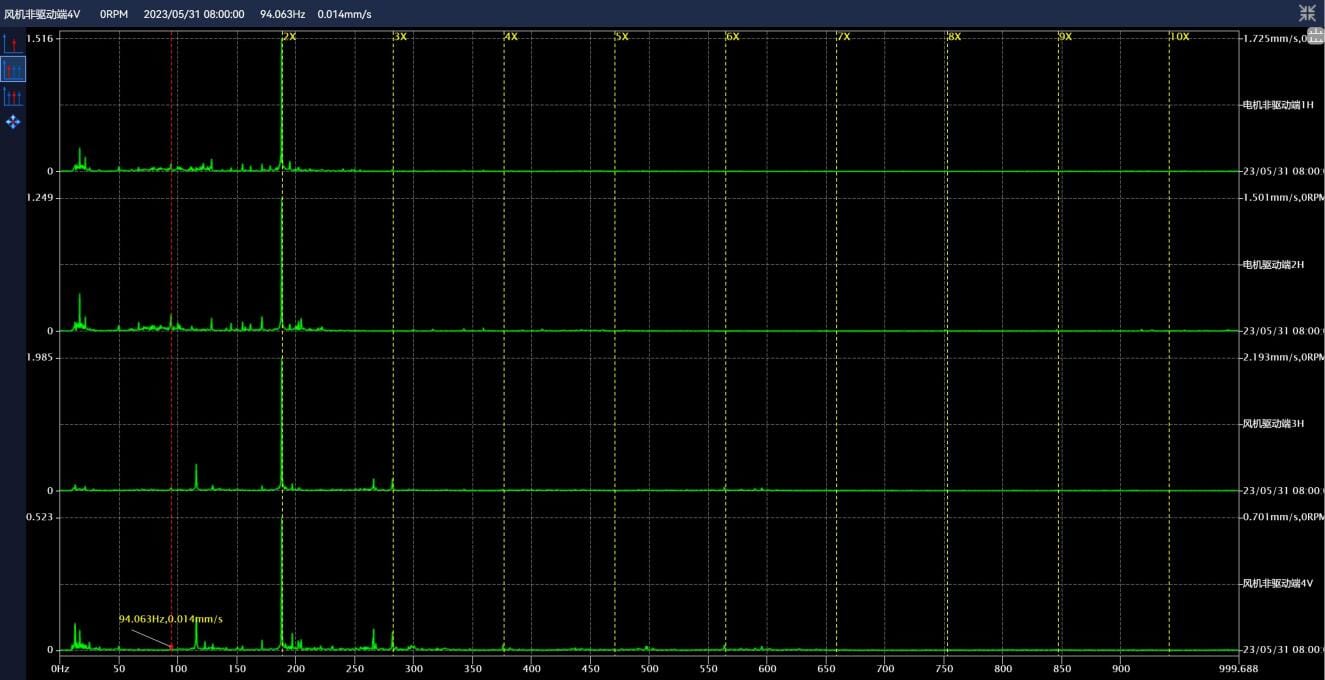

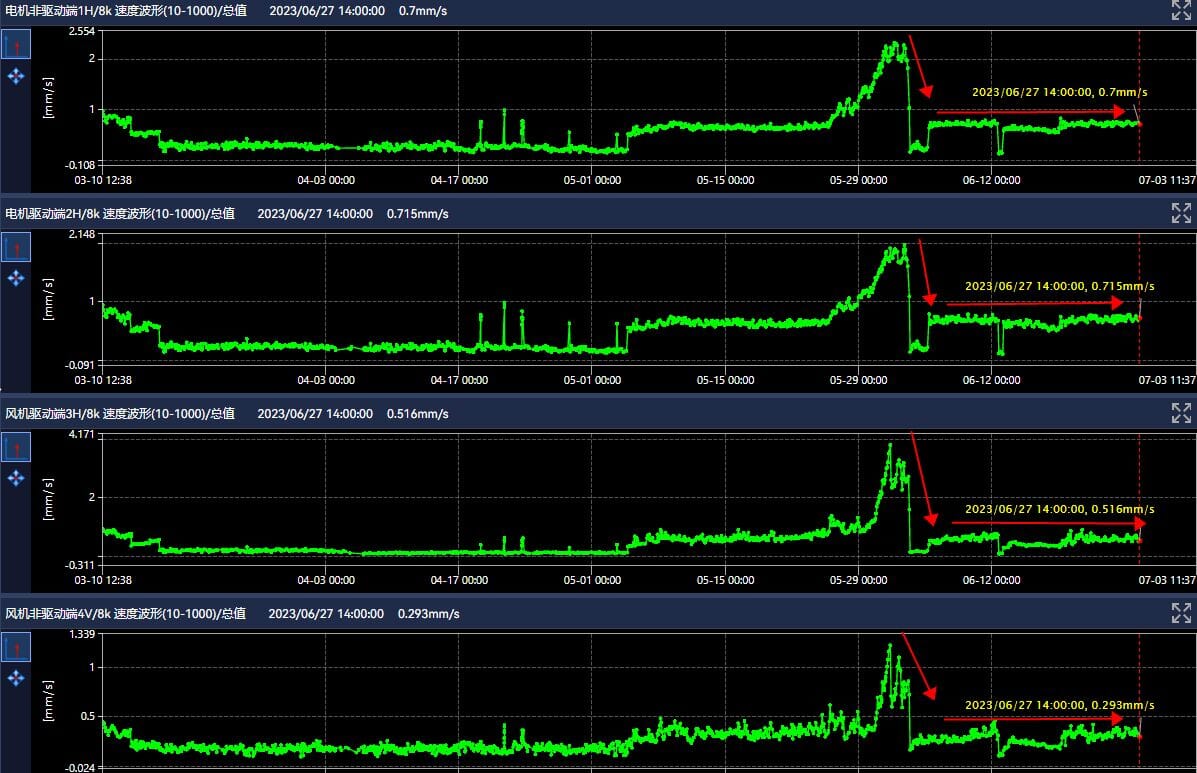

Success Cases

-

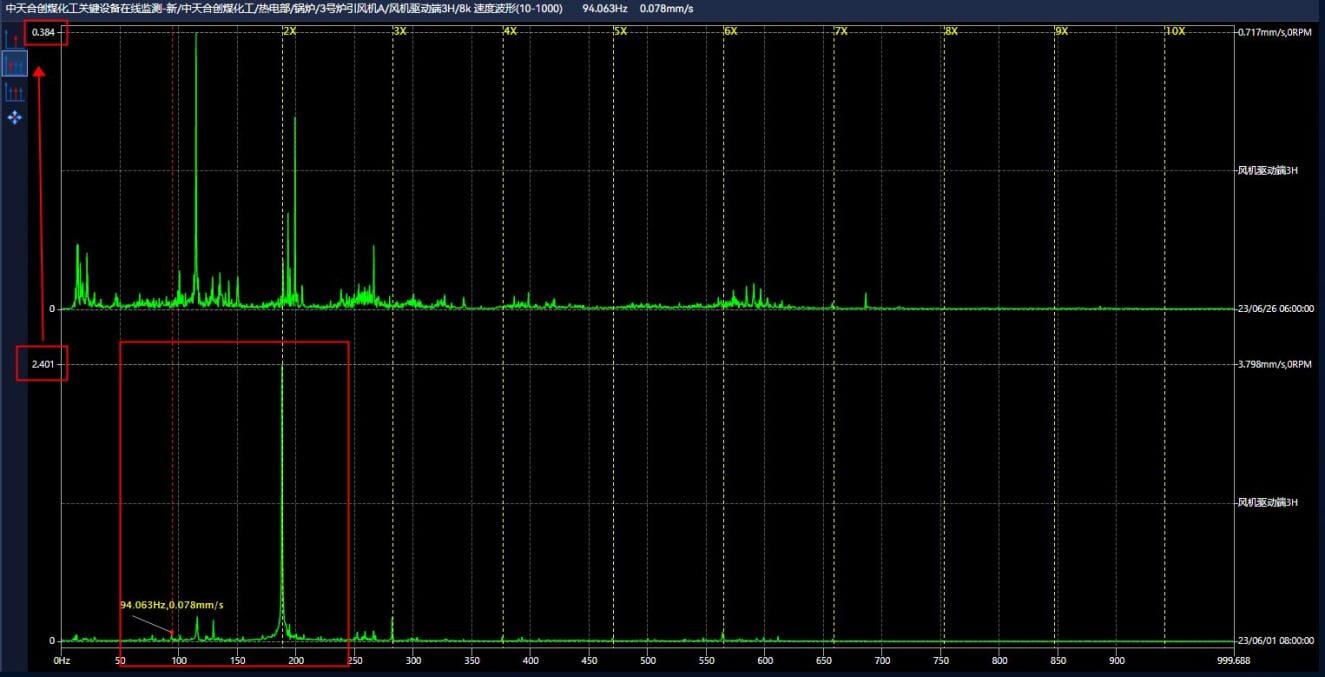

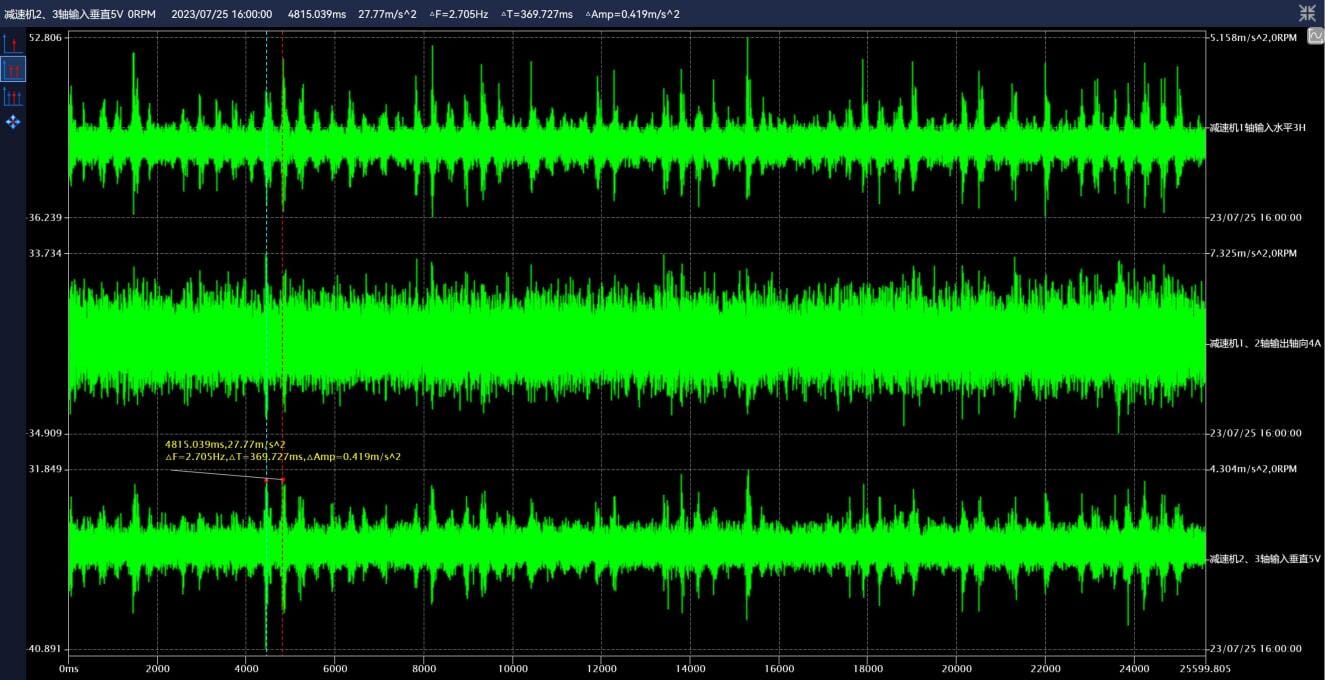

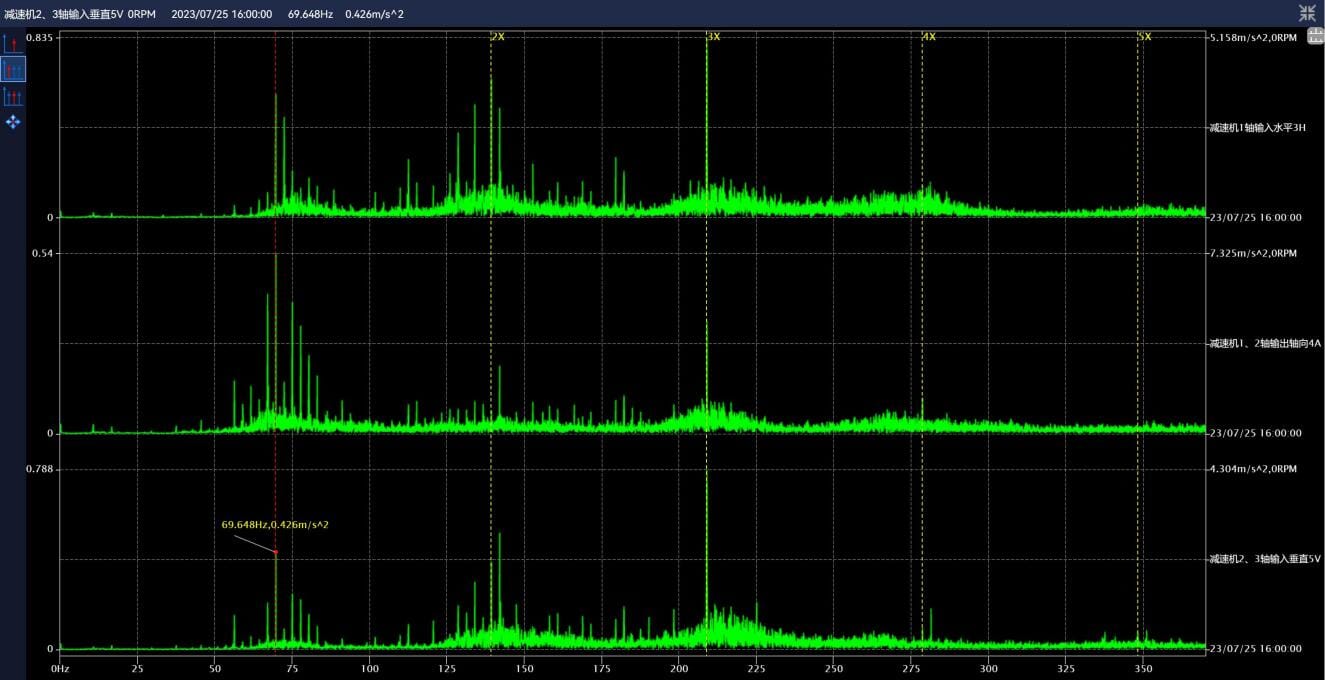

Zhongtian Hechuang Coal Chemical No. 3 furnace induced draft fan A

Zhongtian Hechuang Coal Chemical No. 3 furnace induced draft fan ALearn More

-

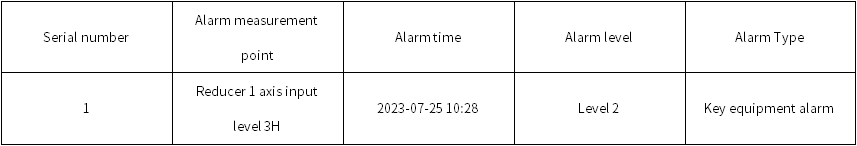

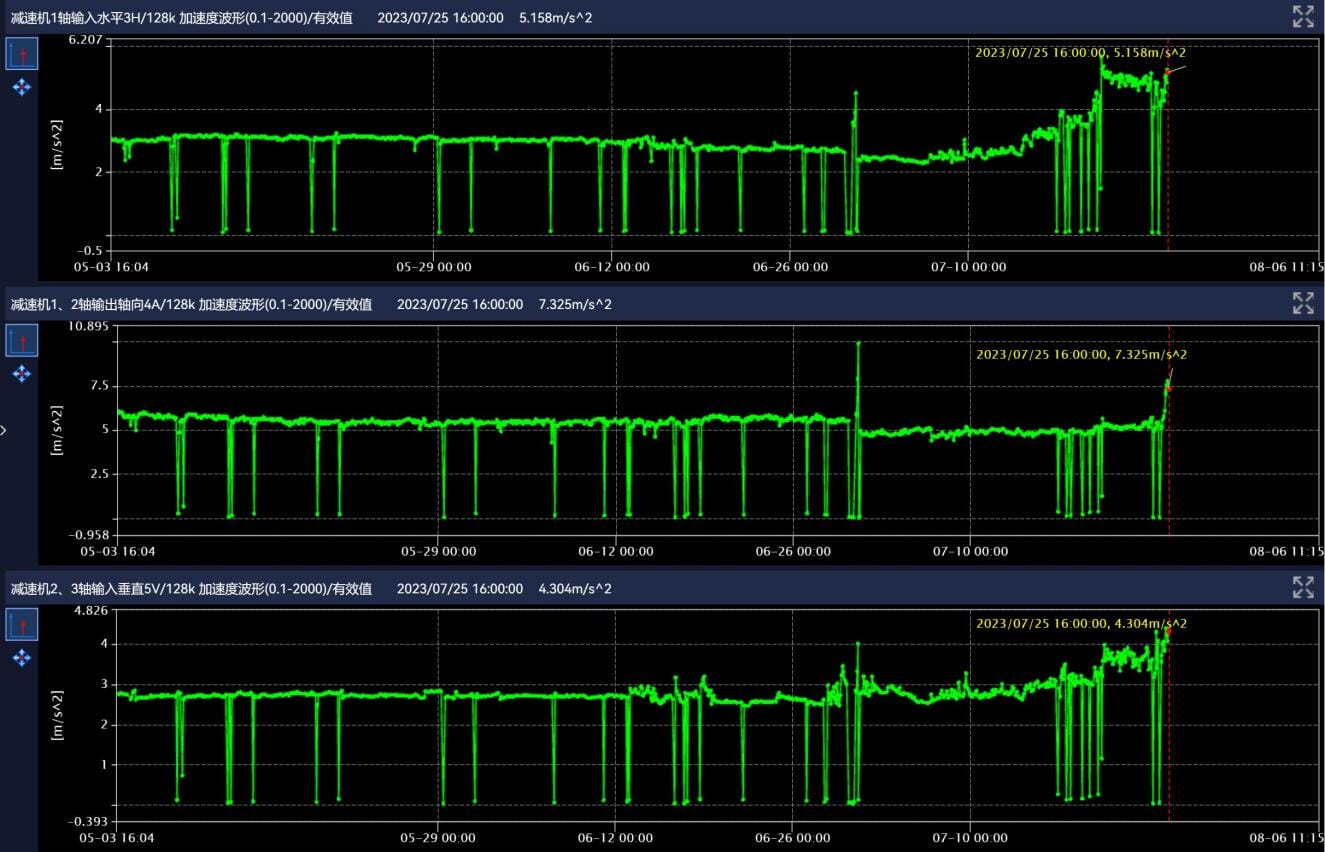

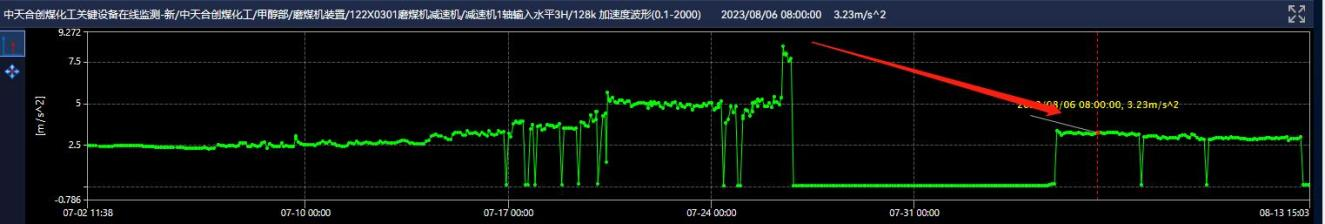

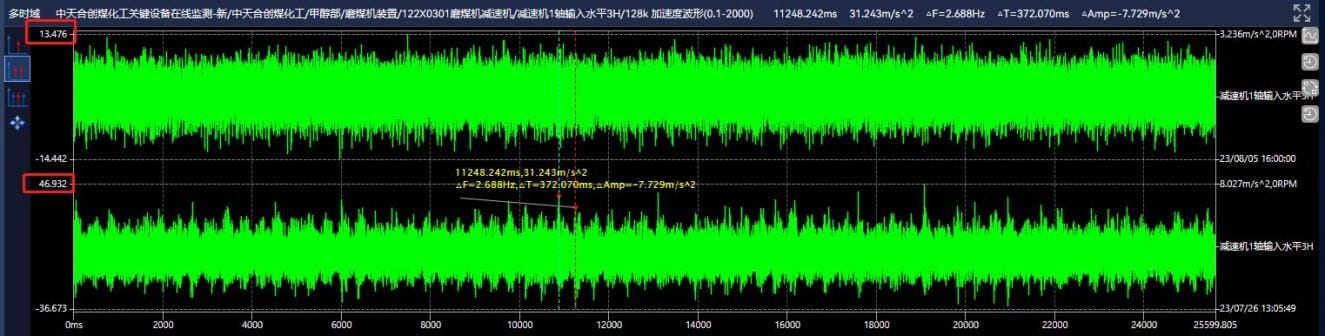

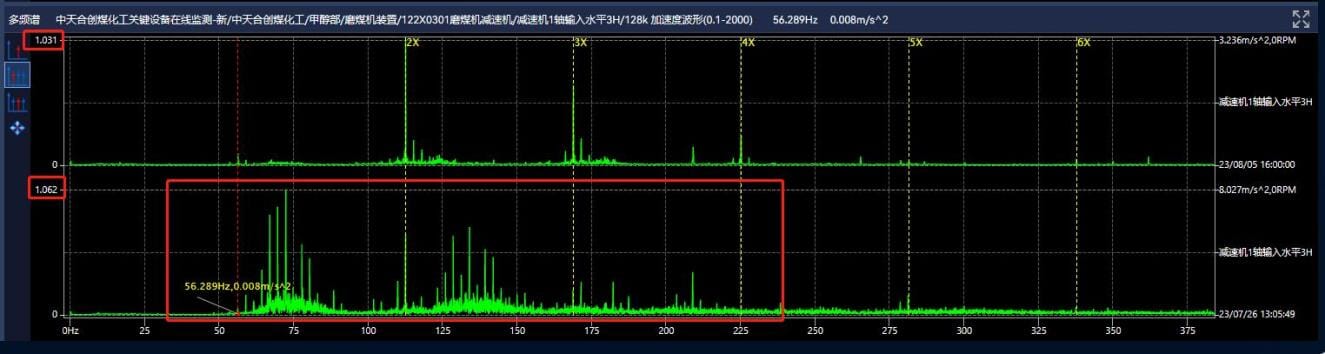

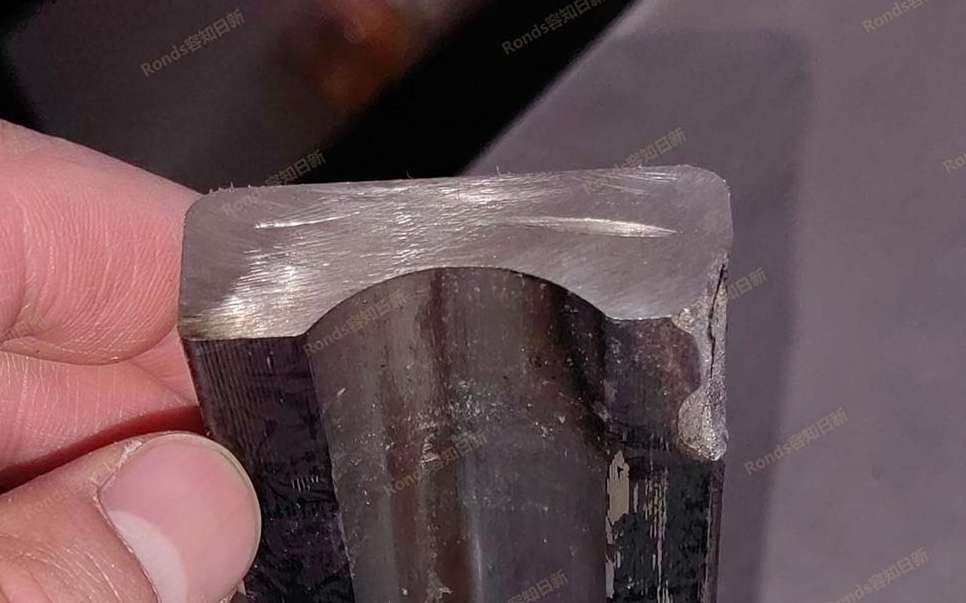

Zhongtian Hechuang Coal Chemical 122X0301 coal mill reducer

Zhongtian Hechuang Coal Chemical 122X0301 coal mill reducerLearn More

-

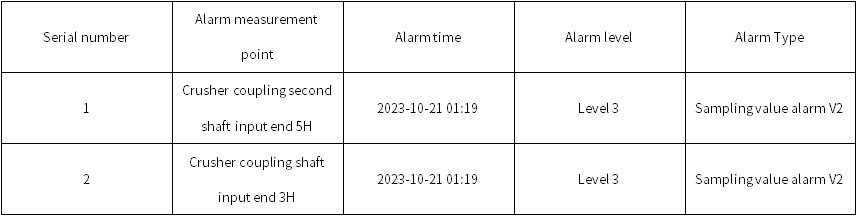

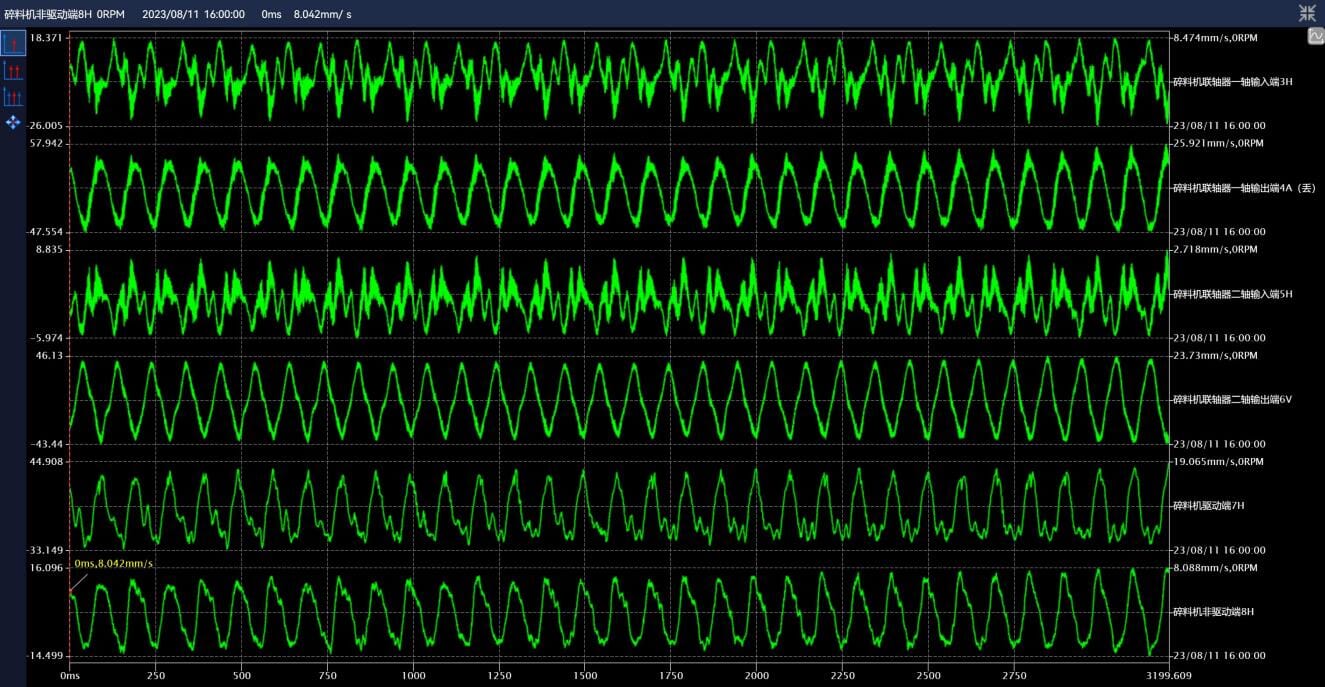

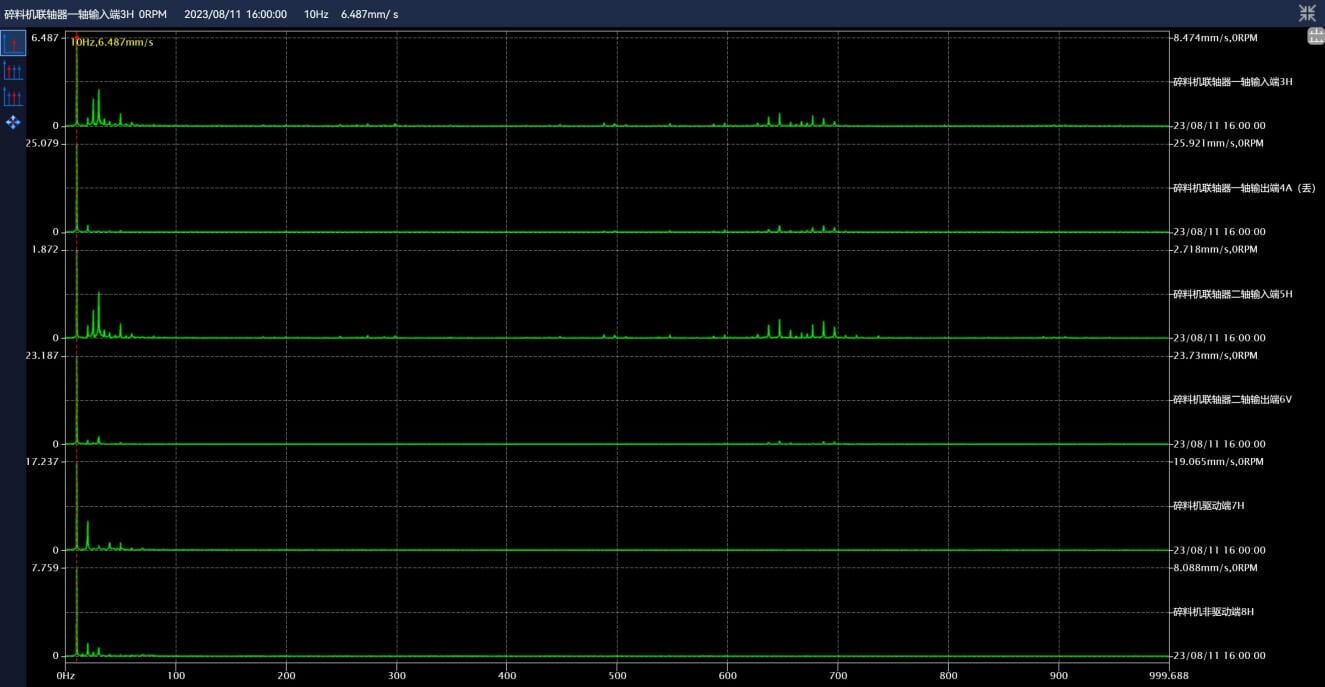

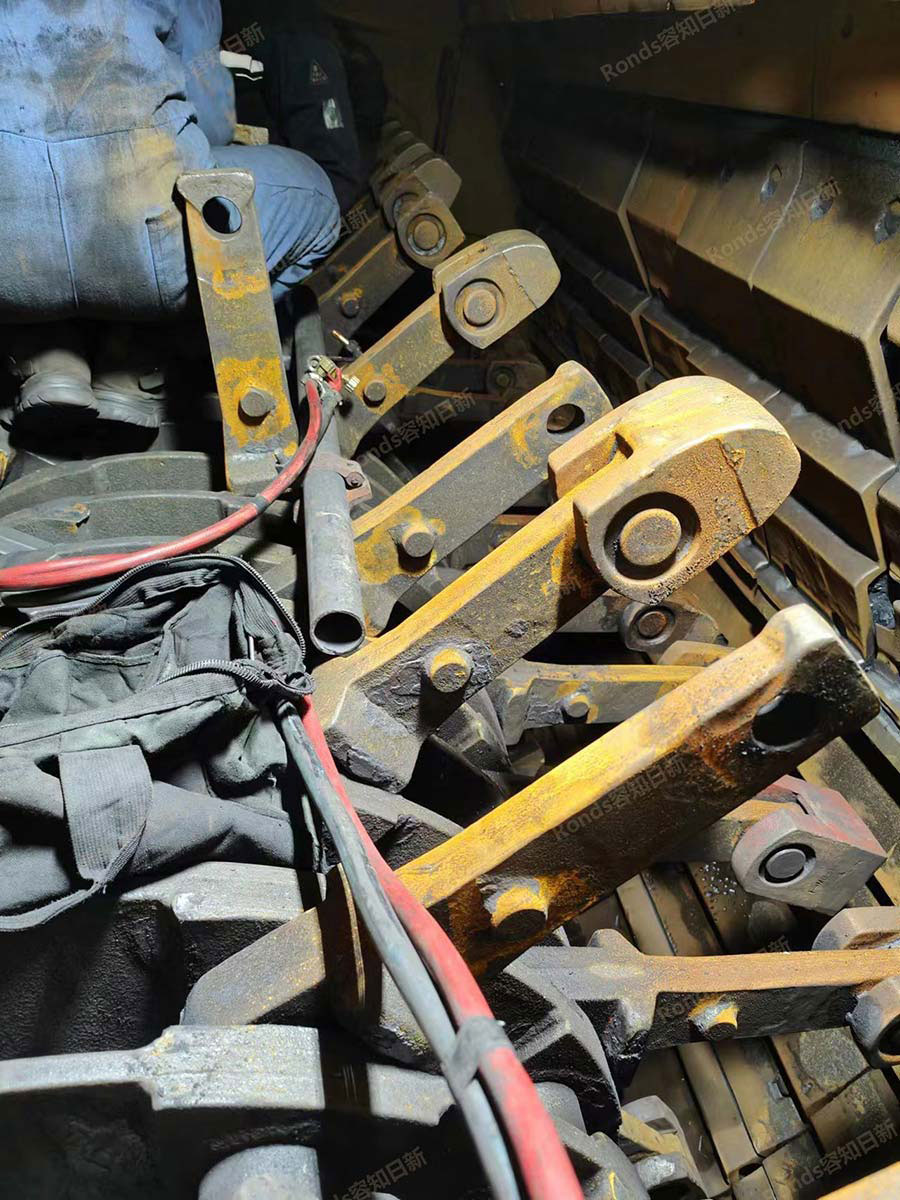

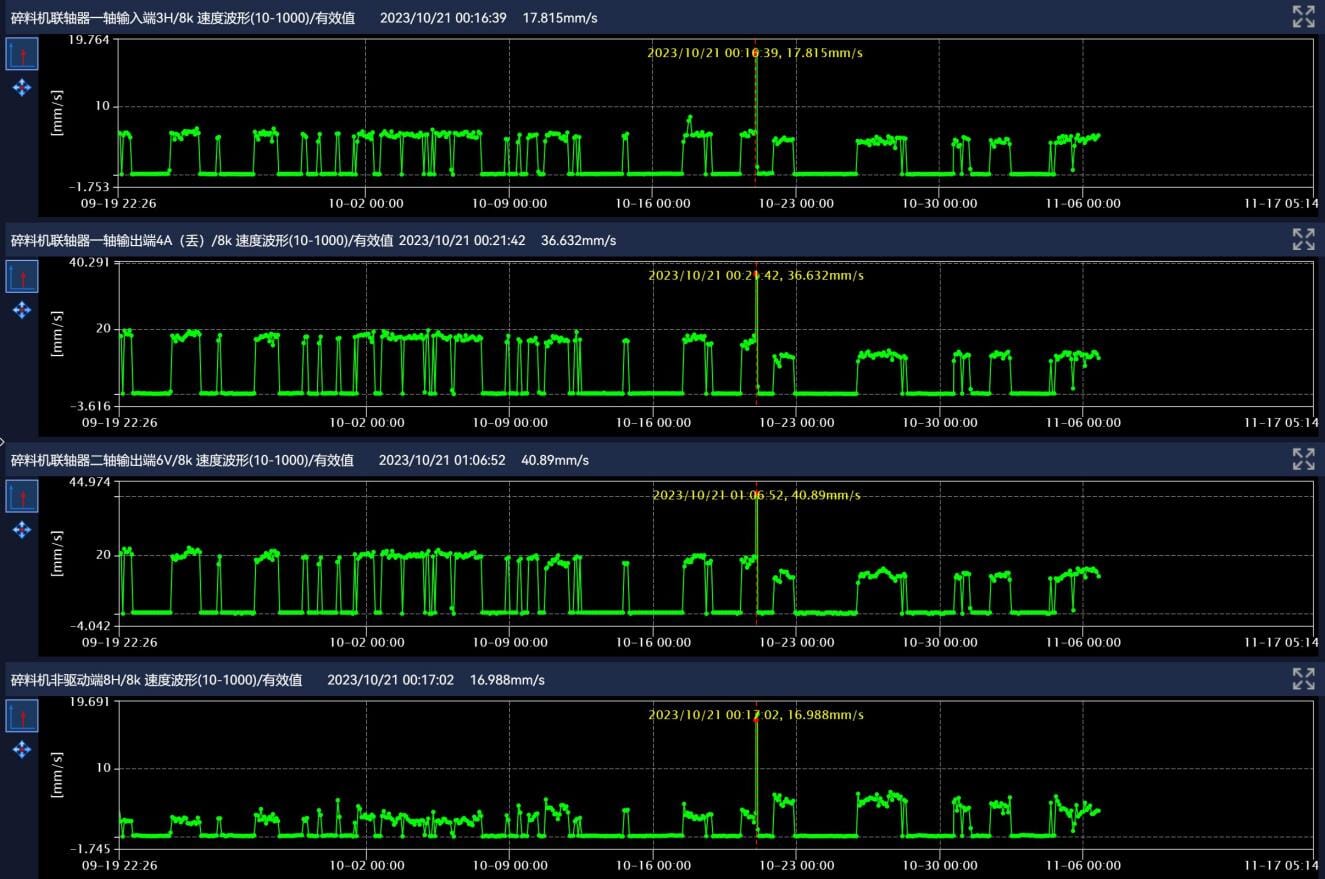

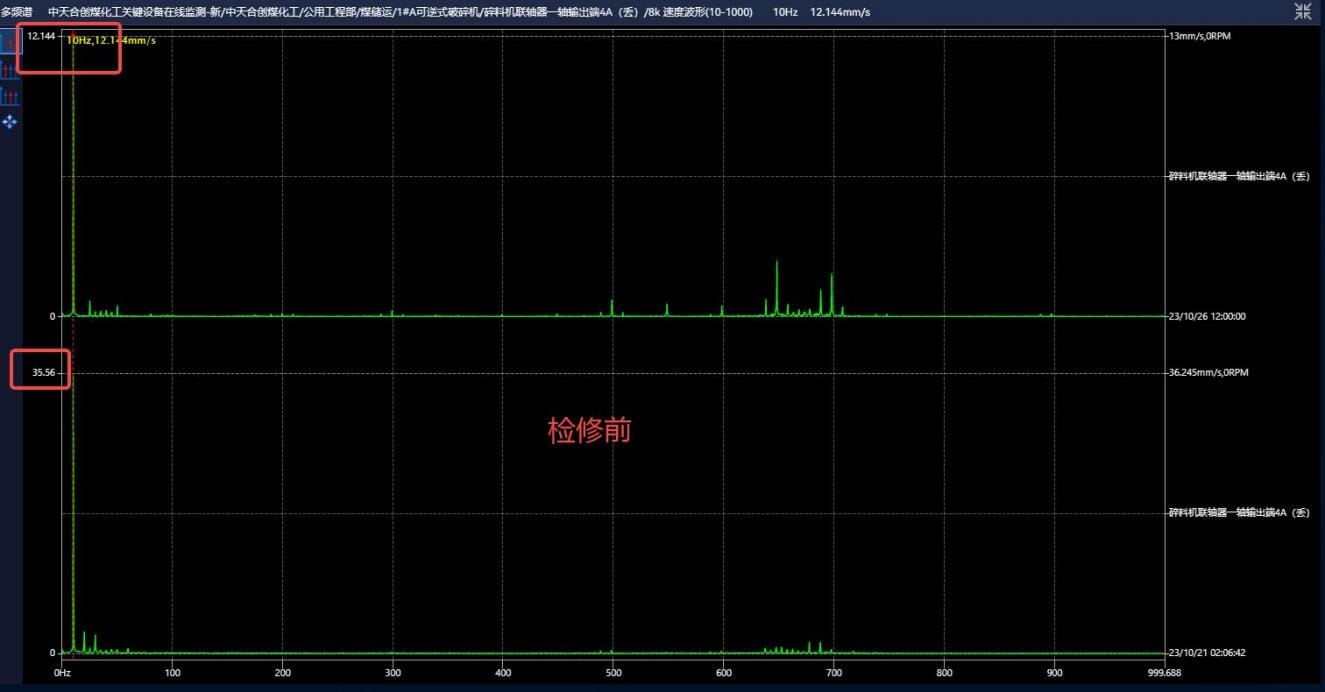

Zhongtian Hechuang Coal Chemical 1#A reversible crusher

Zhongtian Hechuang Coal Chemical 1#A reversible crusherLearn More

-

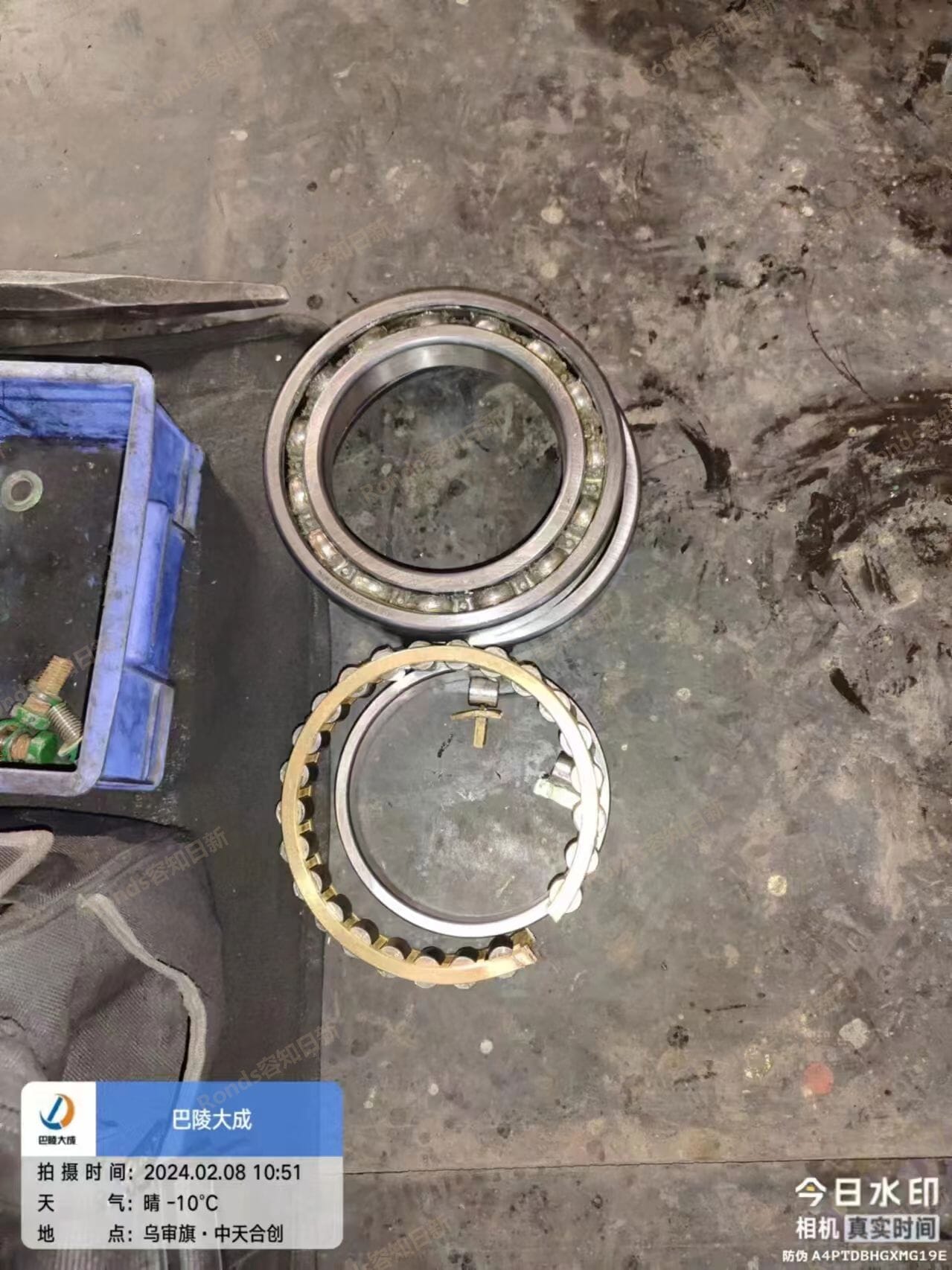

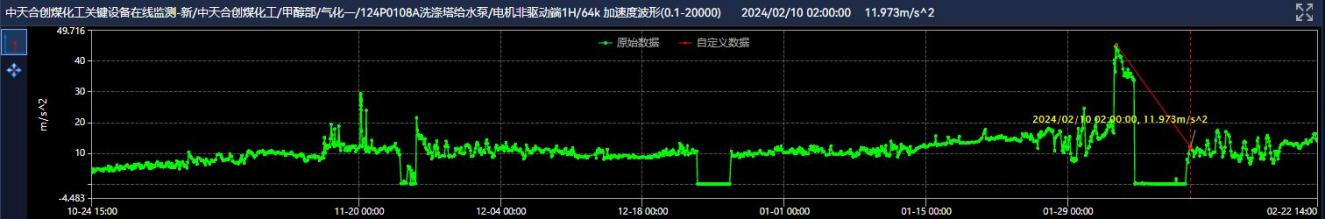

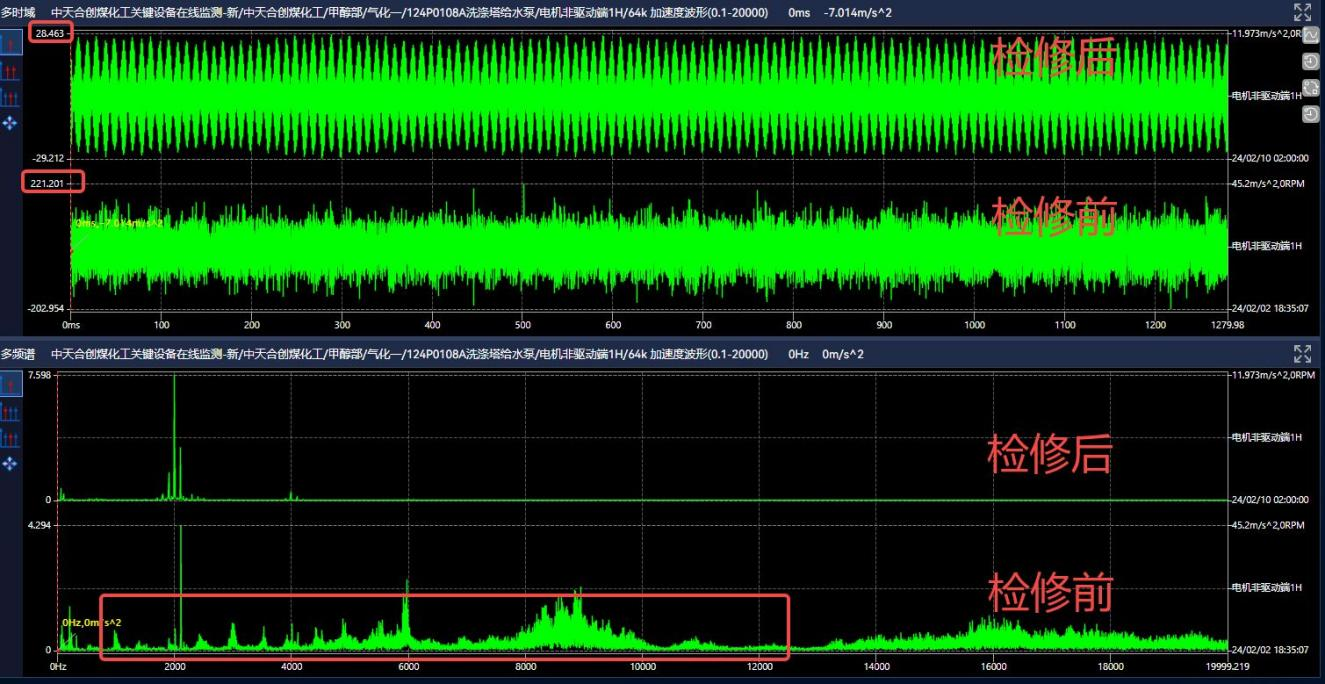

Zhongtian Hechuang Coal Chemical 124P0108A Washing tower water pump

Zhongtian Hechuang Coal Chemical 124P0108A Washing tower water pumpLearn More

Start Your Journey to Intelligent Industrial Equipment Maintenance