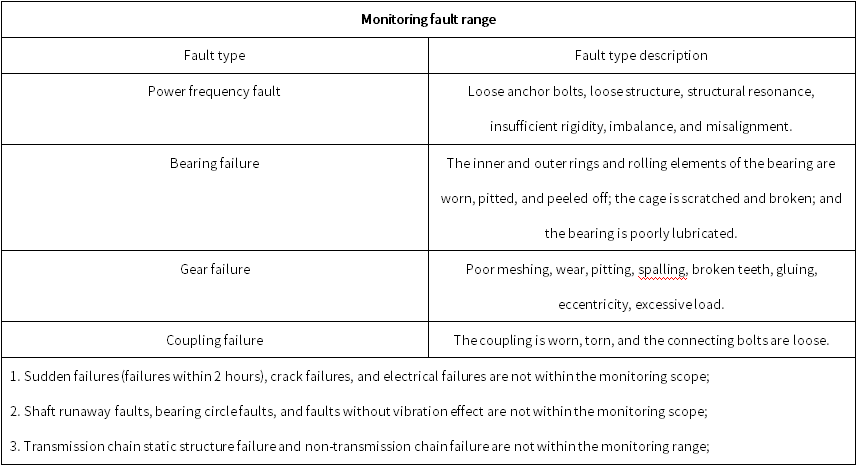

Case Duration:

December 2019 - Present (5+ Years)

Client Background:

Wannianqing Cement is the first listed company in the building materials industry of Jiangxi Province and is the early adopter of domestic new dry-process cement technology line in China.

The company now has six clinker production bases in Wannian, Yushan, Ruijin, Yudu, Leping and De'an, seven grinding enterprises, with annual clinker production capacity of 15 million tons and cement production capacity of 26 million tons, and a high brand awareness and customer recognition in East China.

Client Requirements & Solutions

Assist enterprises to build high-speed and efficient intelligent operation and maintenance system

Deploy online monitoring systems to improve efficiency:

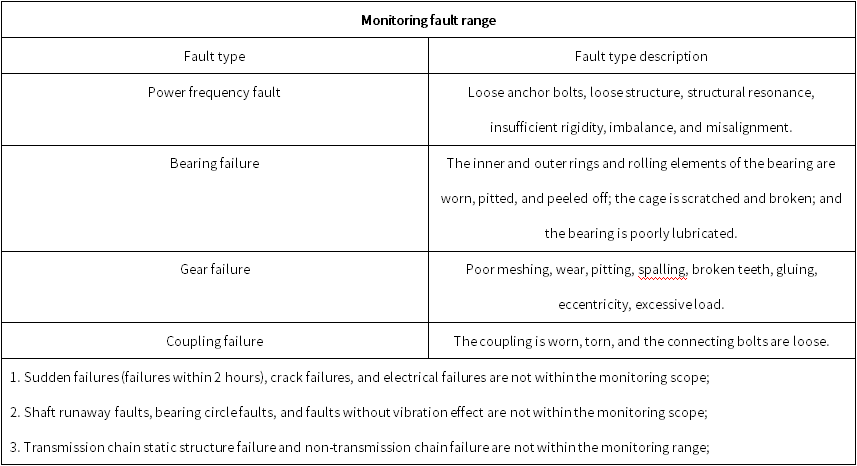

Deploying online monitoring systems for key equipment in various plant areas enables real-time access to equipment status data, ensuring timely alerts. This facilitates remote automatic inspection of equipment, early prediction of equipment issues, and the rational formulation of maintenance plans. As a result, it significantly reduces the daily inspection pressure on maintenance personnel and enhances their capabilities.

Construct high-speed and efficient Intelligent operation and maintenance system:

Use 5G technology to build a fast and stable communication system, guaranteeing fast and real-time mastery of equipment status data, and effectively guaranteeing the timeliness of alarms. Online monitoring combines the experience and knowledge of Ronds experts and the client's experts to assist the client in building an efficient intelligent operation and maintenance system.

Application Value

Operational cost reduction and Efficiency improvement, ensure equipment safety:

Ronds has deployed online monitoring in the four major bases of Ruijin, Dean, Le'an, and Wannian. Since December 2020, over 120 closed-loop cases of various equipment failures have been generated. In just one base, Ruijin Wannianqing, direct economic losses were reduced by $0.241 million in 2020 and reached $0.609 million in 2021.

Technological achievements transfer:

The online monitoring system built with 5G technology was successfully selected as the benchmark project of Jiangxi Province's "03 Special Projects", with outstanding achievements in technology transfer.

Enhance the professionalism and job satisfaction of operation and maintenance personnel:

Long-term and effective online monitoring allows operation and maintenance personnel to develop a more scientific and rational equipment maintenance mechanism, reducing their workload and significantly improving overall maintenance efficiency.

Success Cases

-

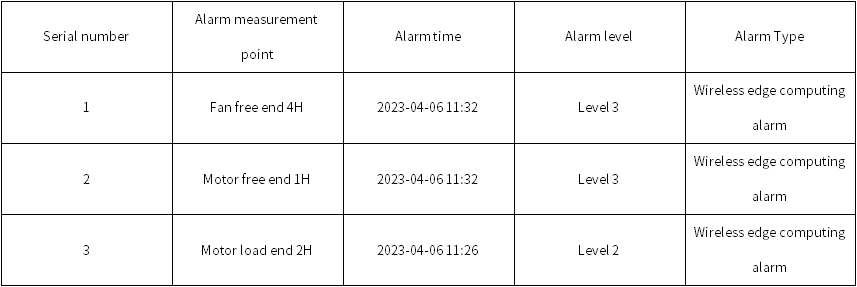

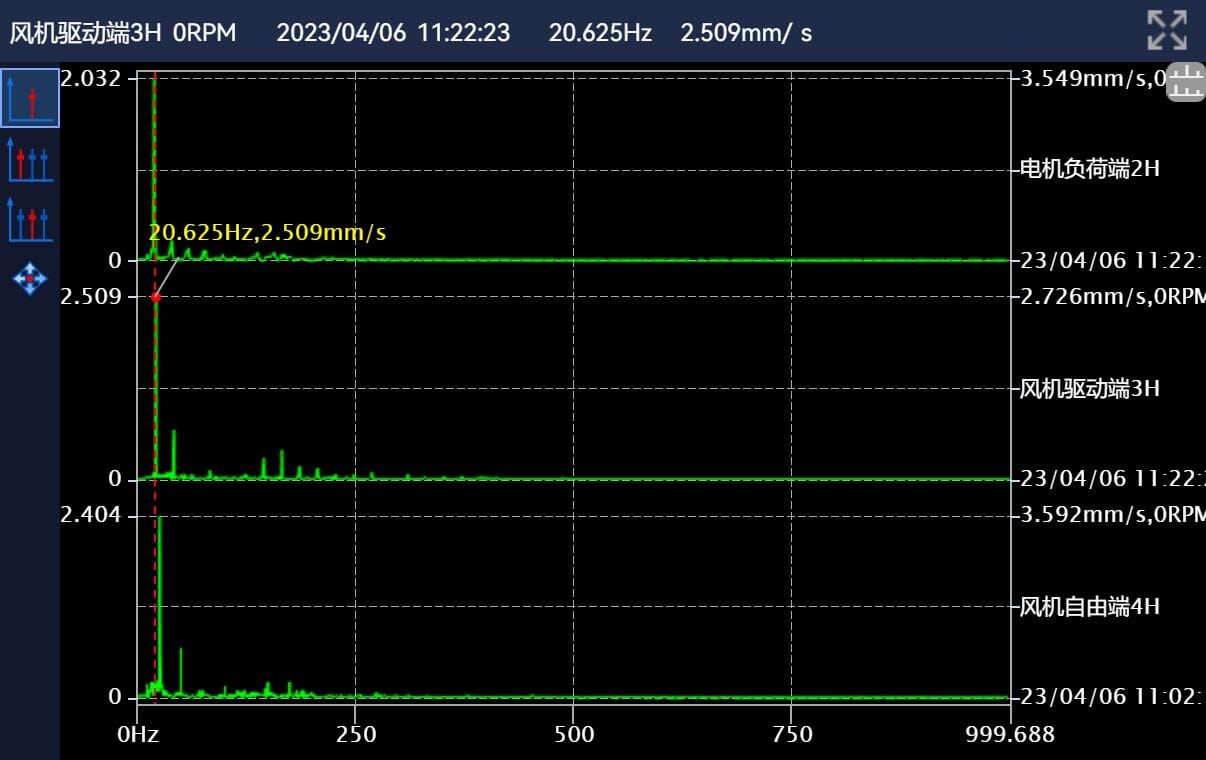

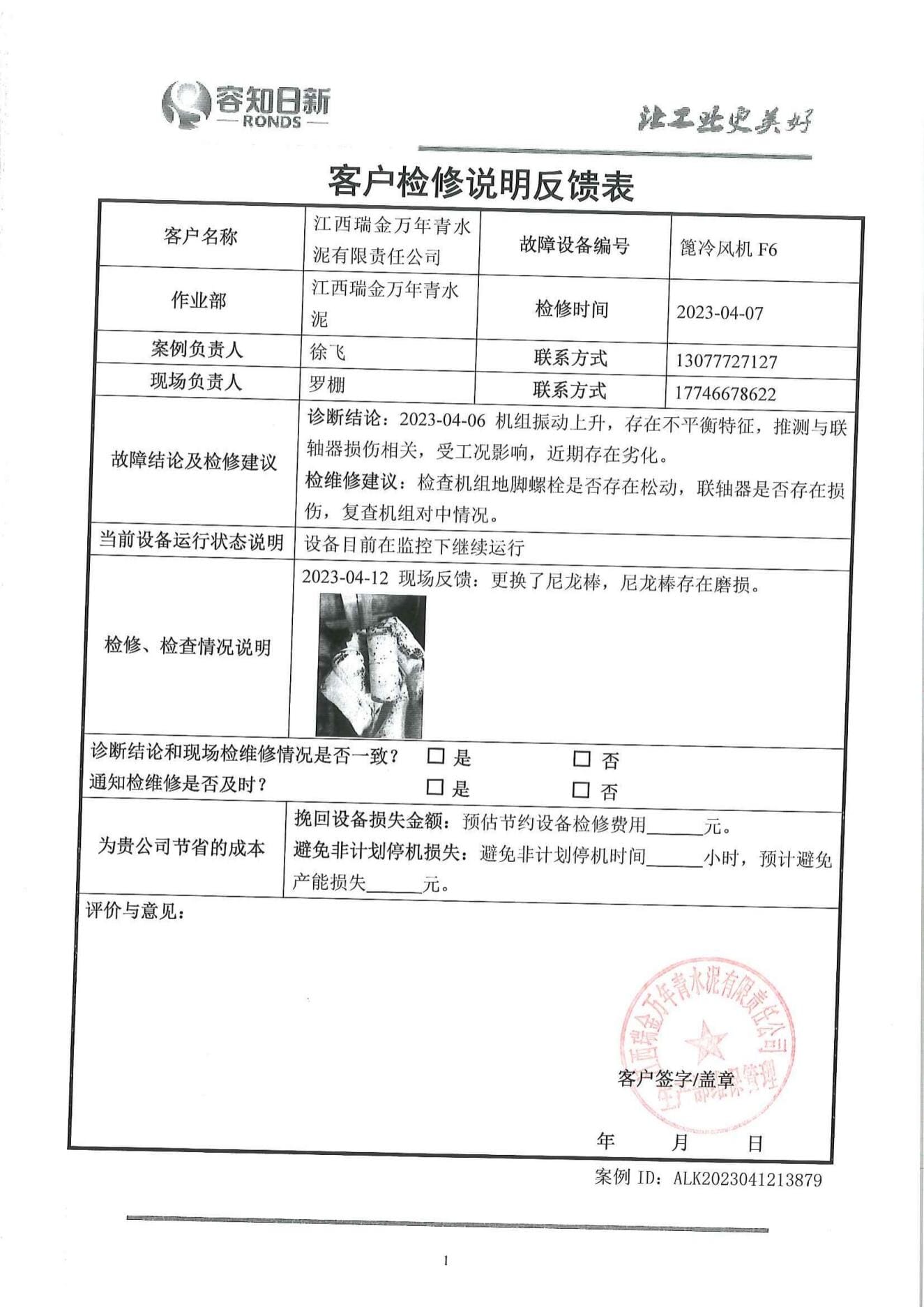

Jiangxi Ruijin Wannianqing Cement Co., Ltd. Grate Cooler F6

Jiangxi Ruijin Wannianqing Cement Co., Ltd. Grate Cooler F6Learn More

-

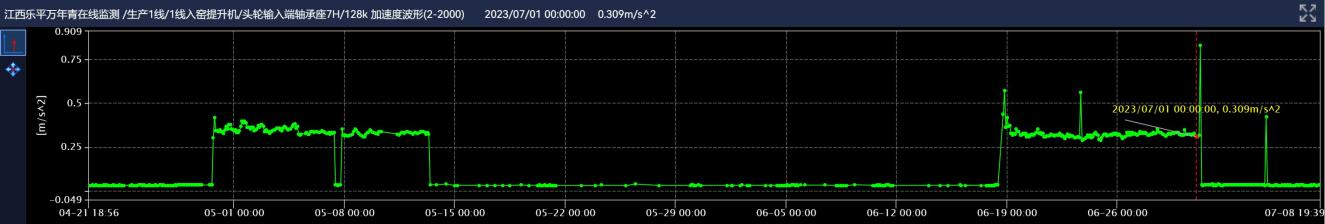

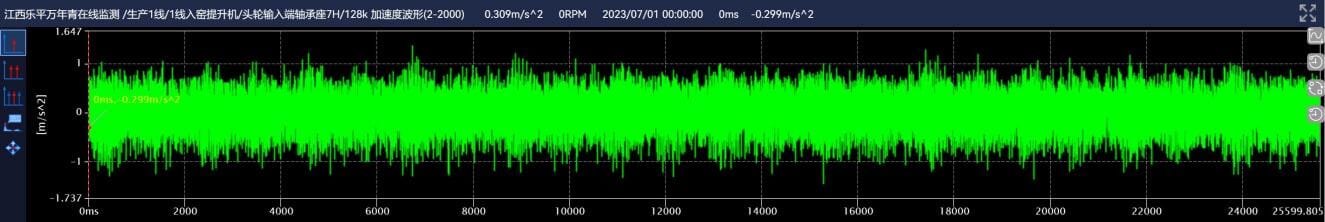

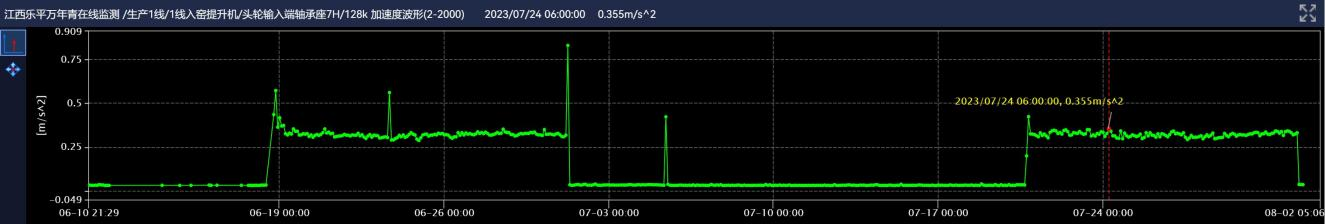

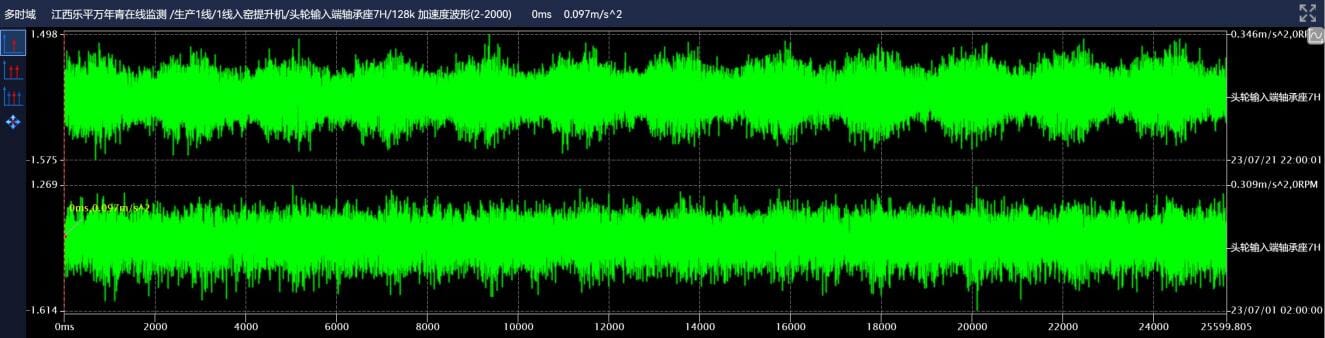

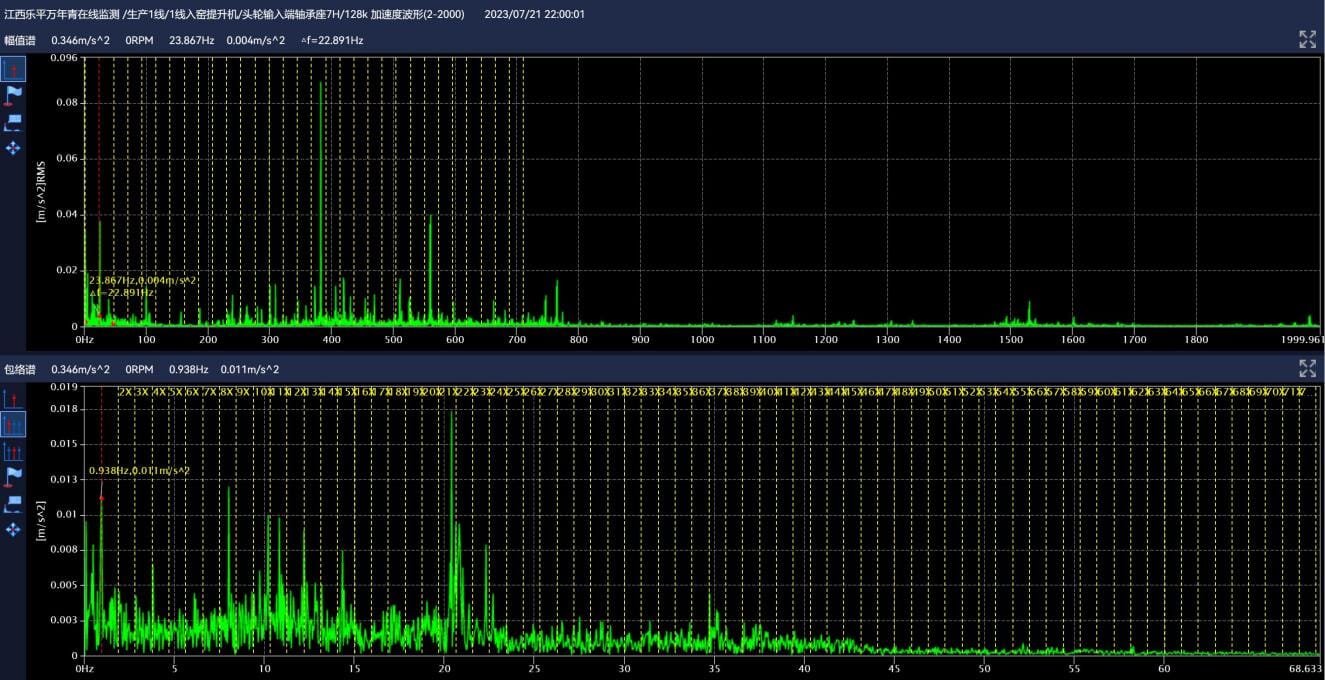

Leping Wannianqing Cement Line 1 kiln elevator

Leping Wannianqing Cement Line 1 kiln elevatorLearn More

-

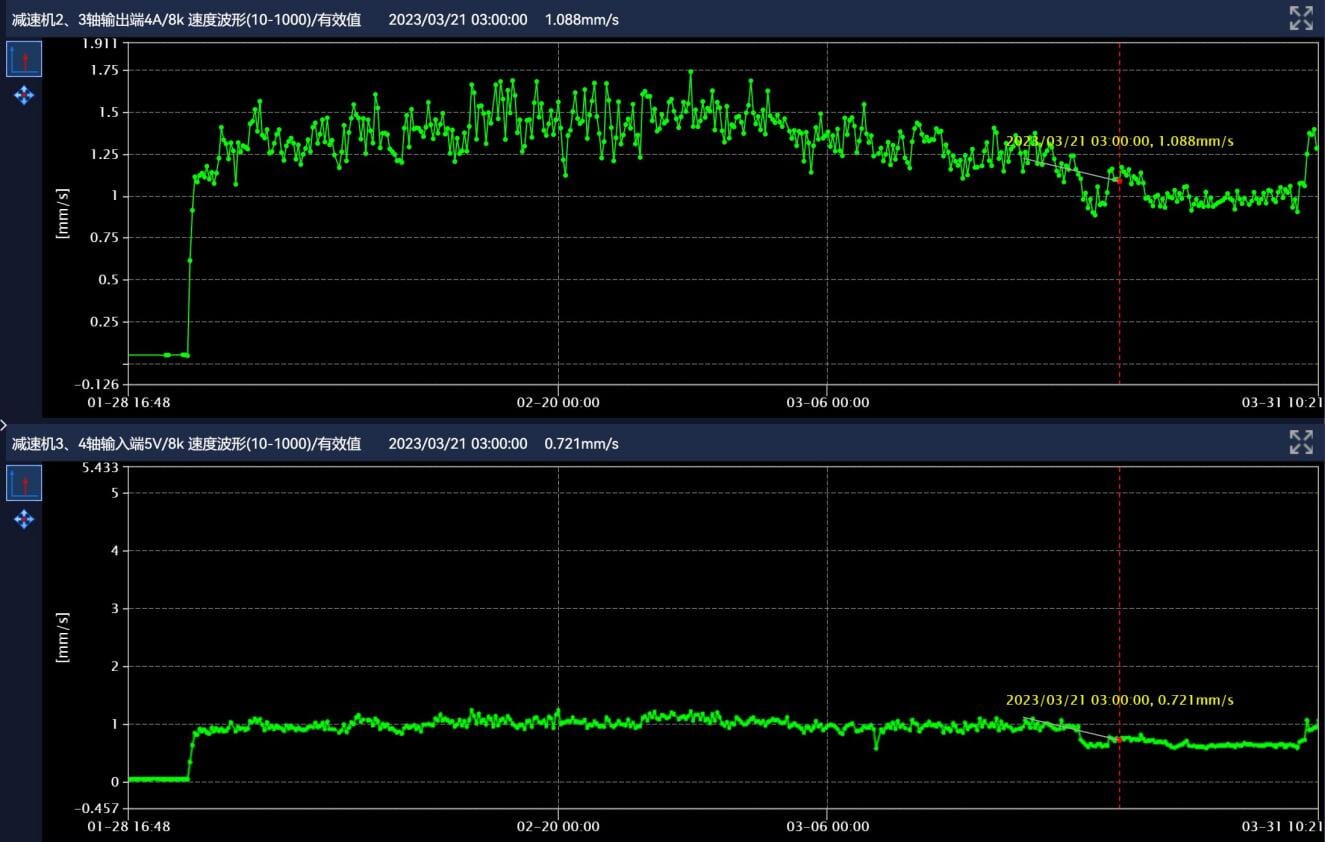

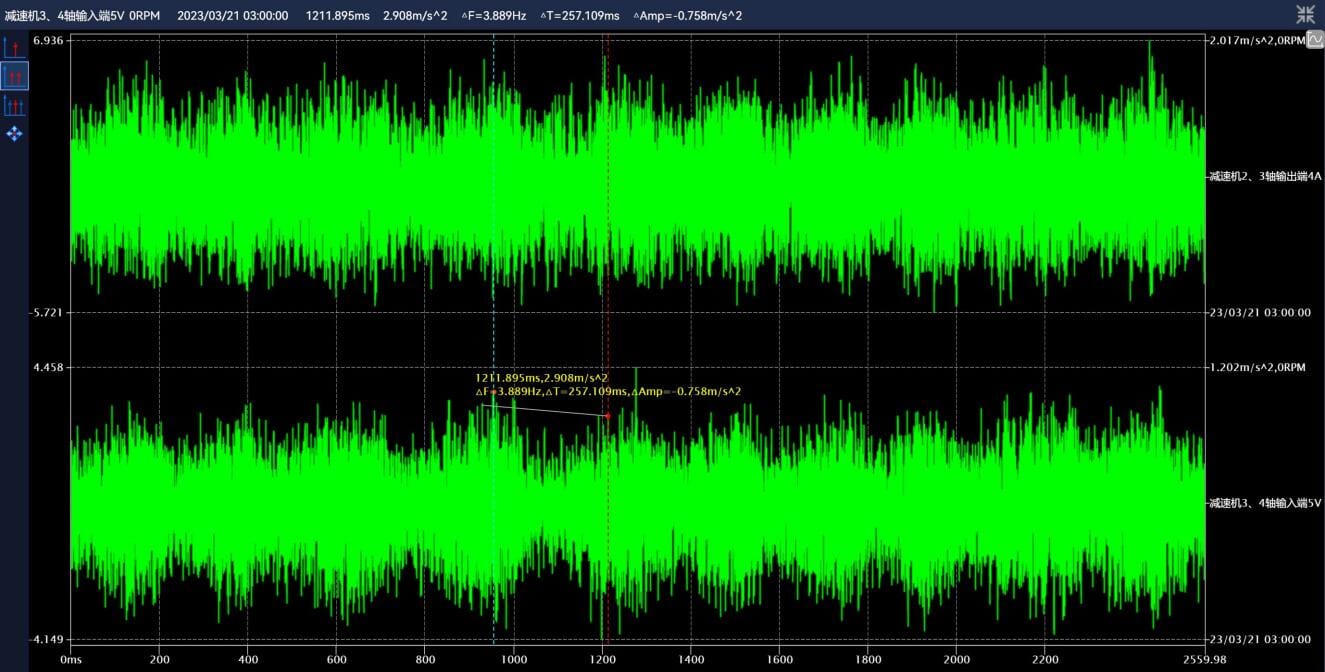

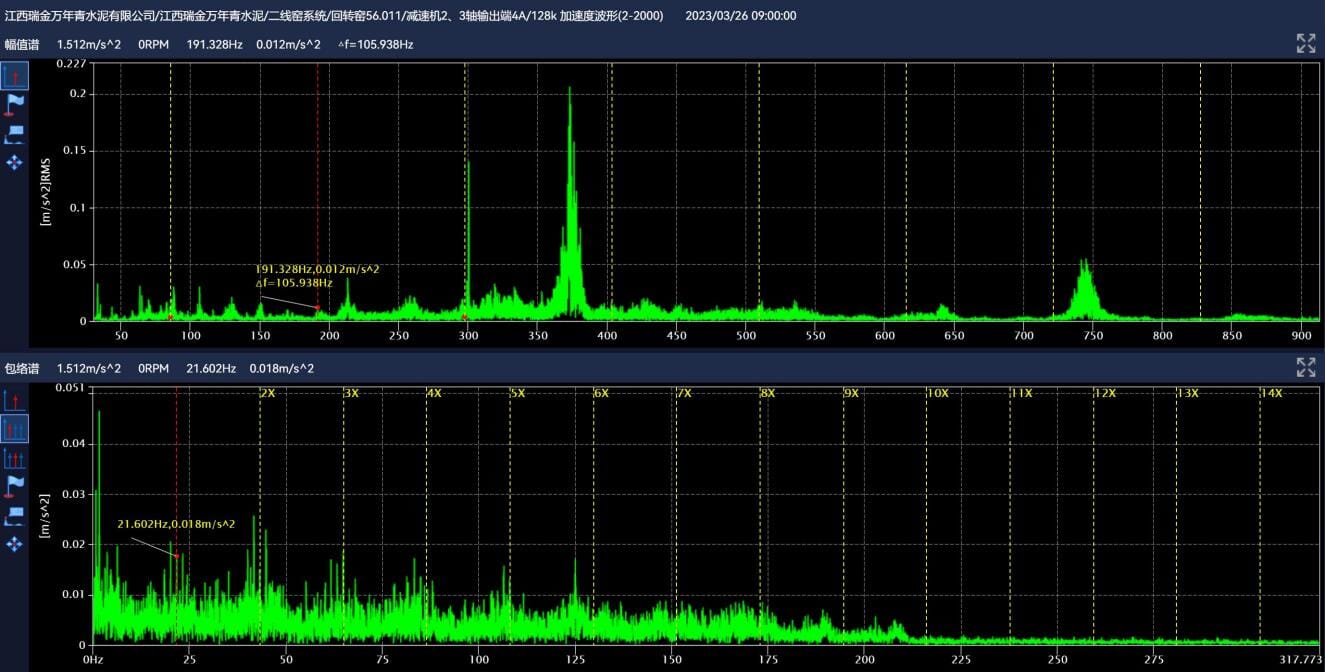

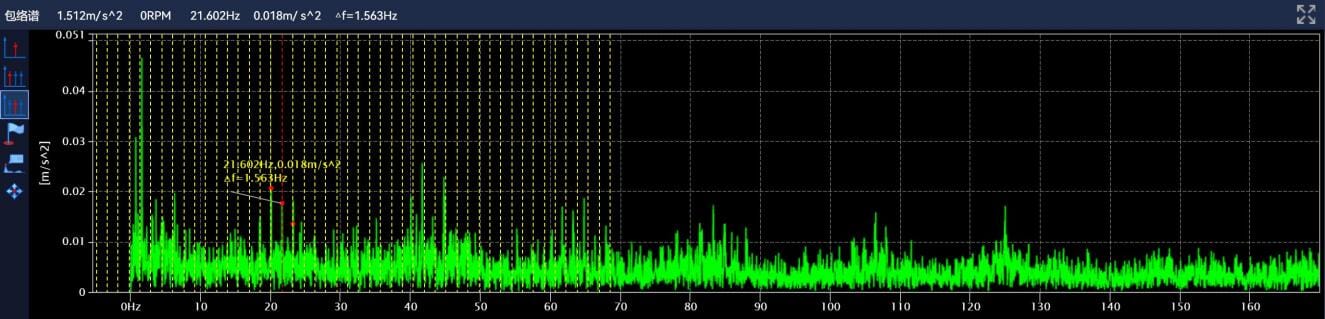

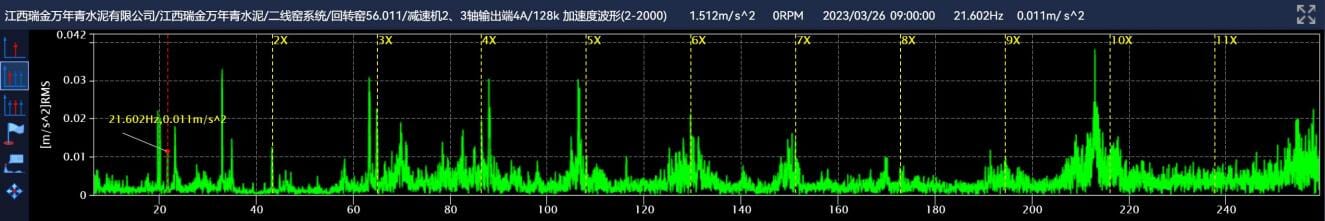

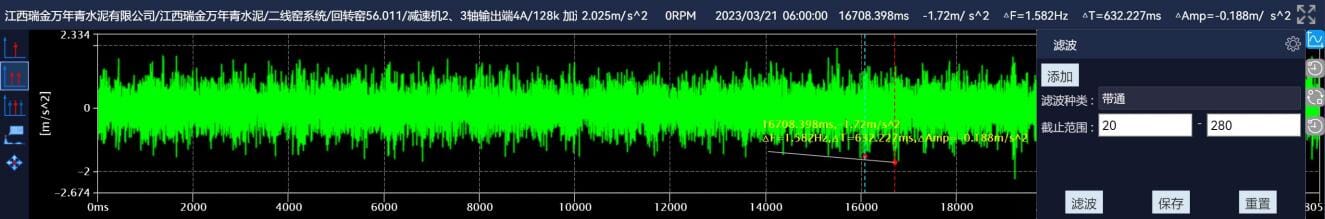

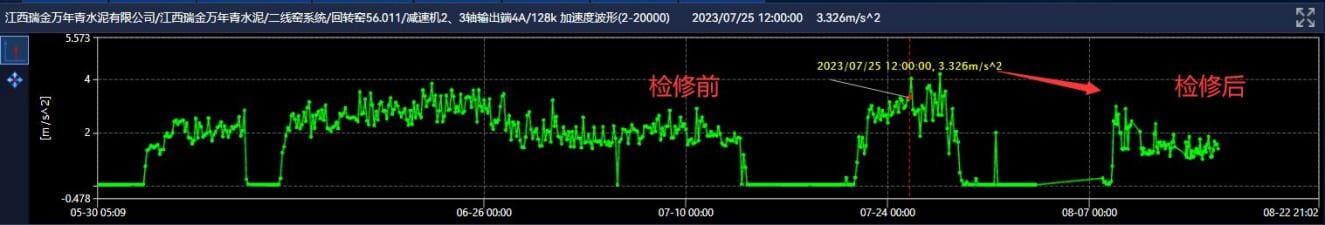

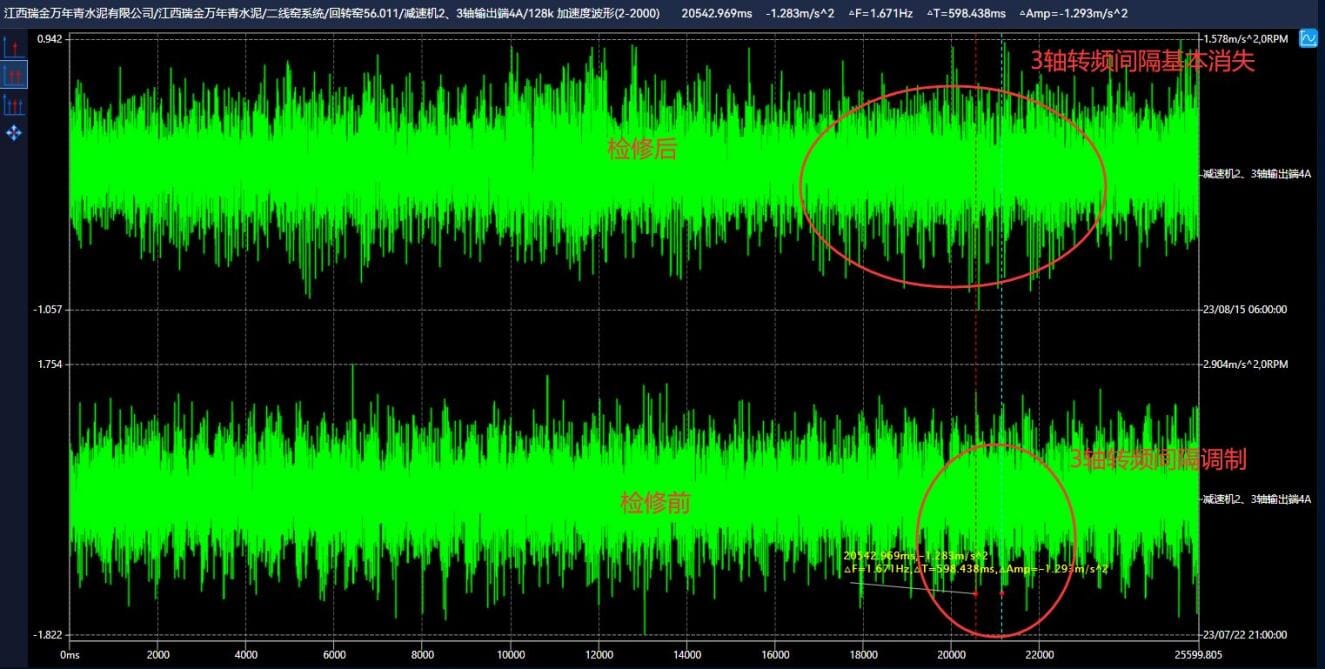

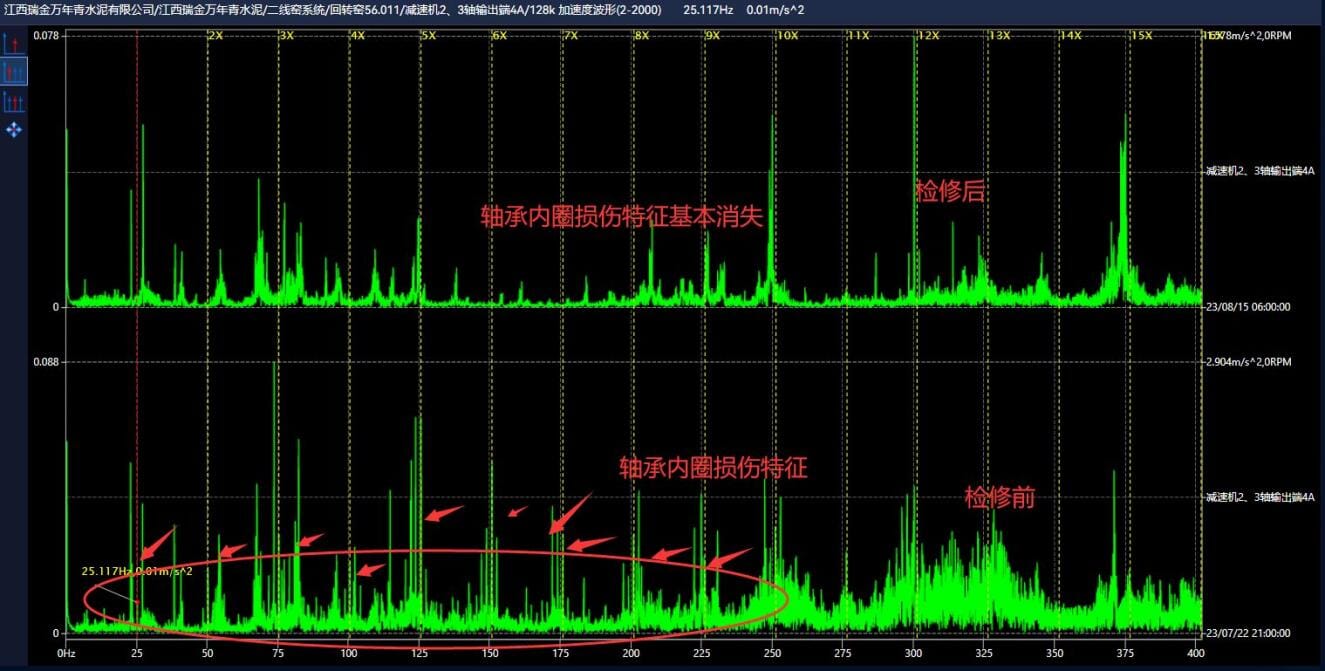

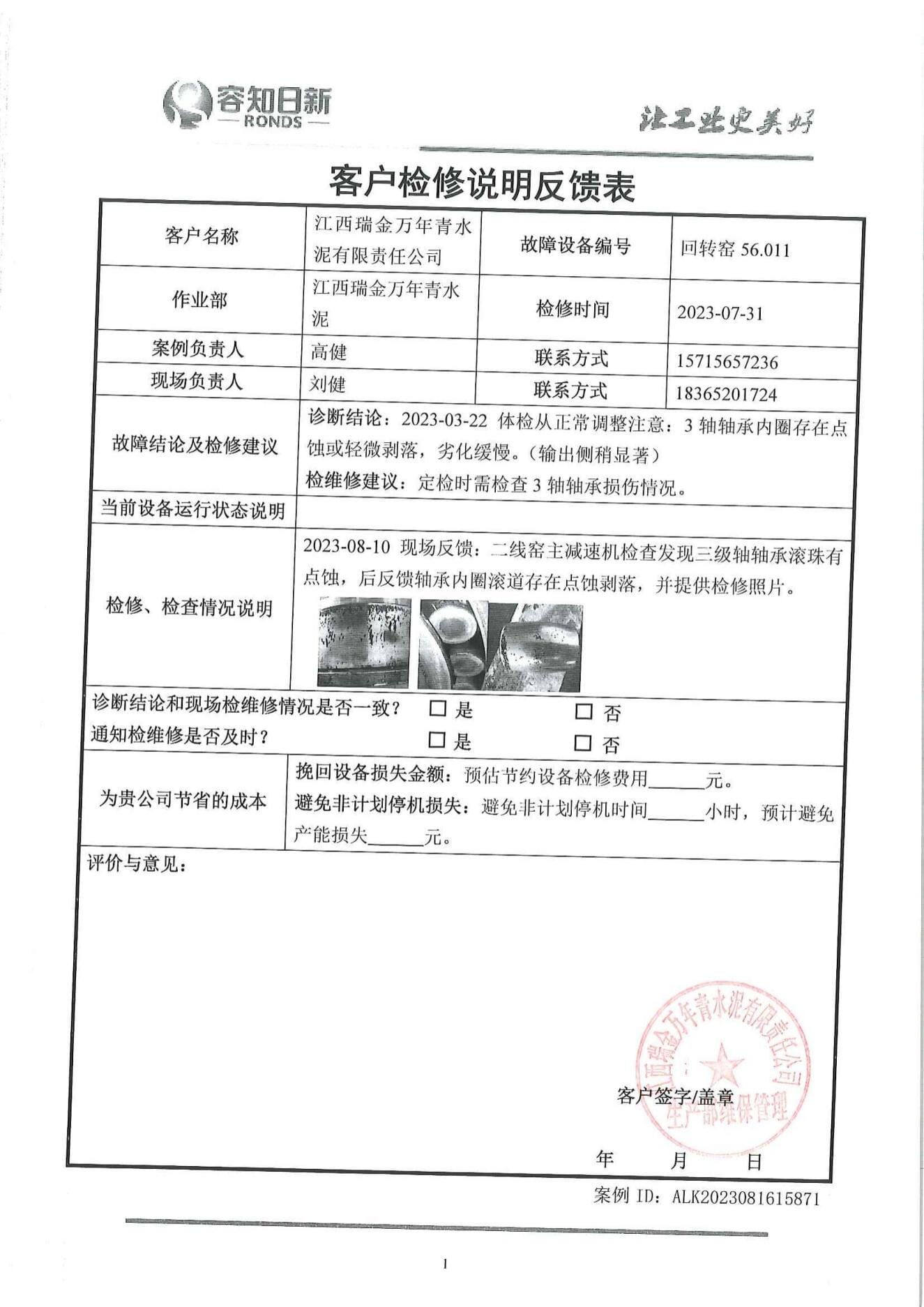

Jiangxi Ruijin Wannianqing Cement Co., Ltd. Rotary Kiln 56.011

Jiangxi Ruijin Wannianqing Cement Co., Ltd. Rotary Kiln 56.011Learn More

-

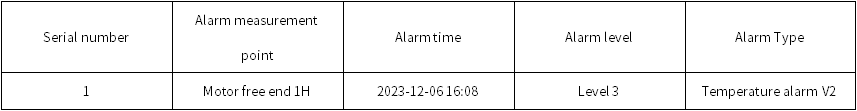

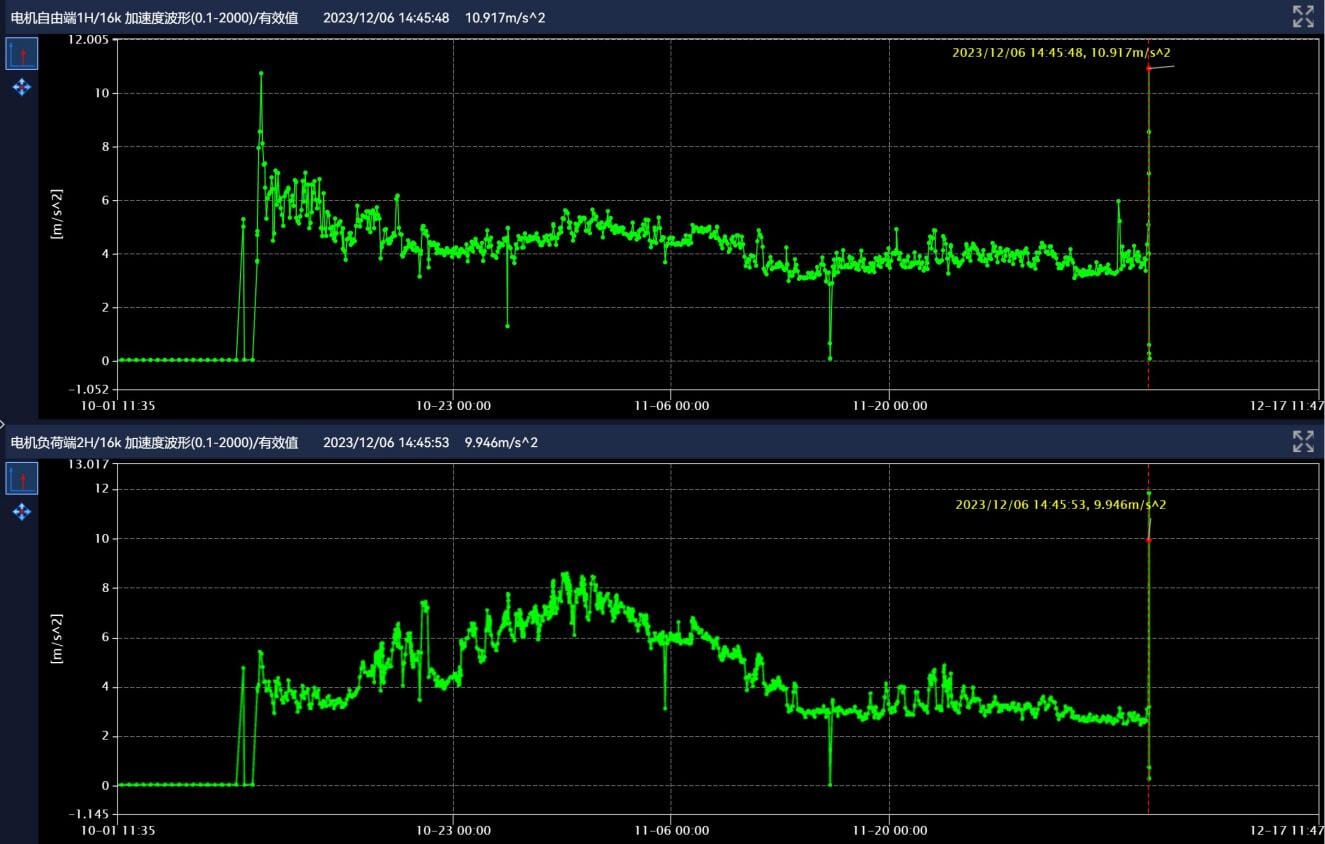

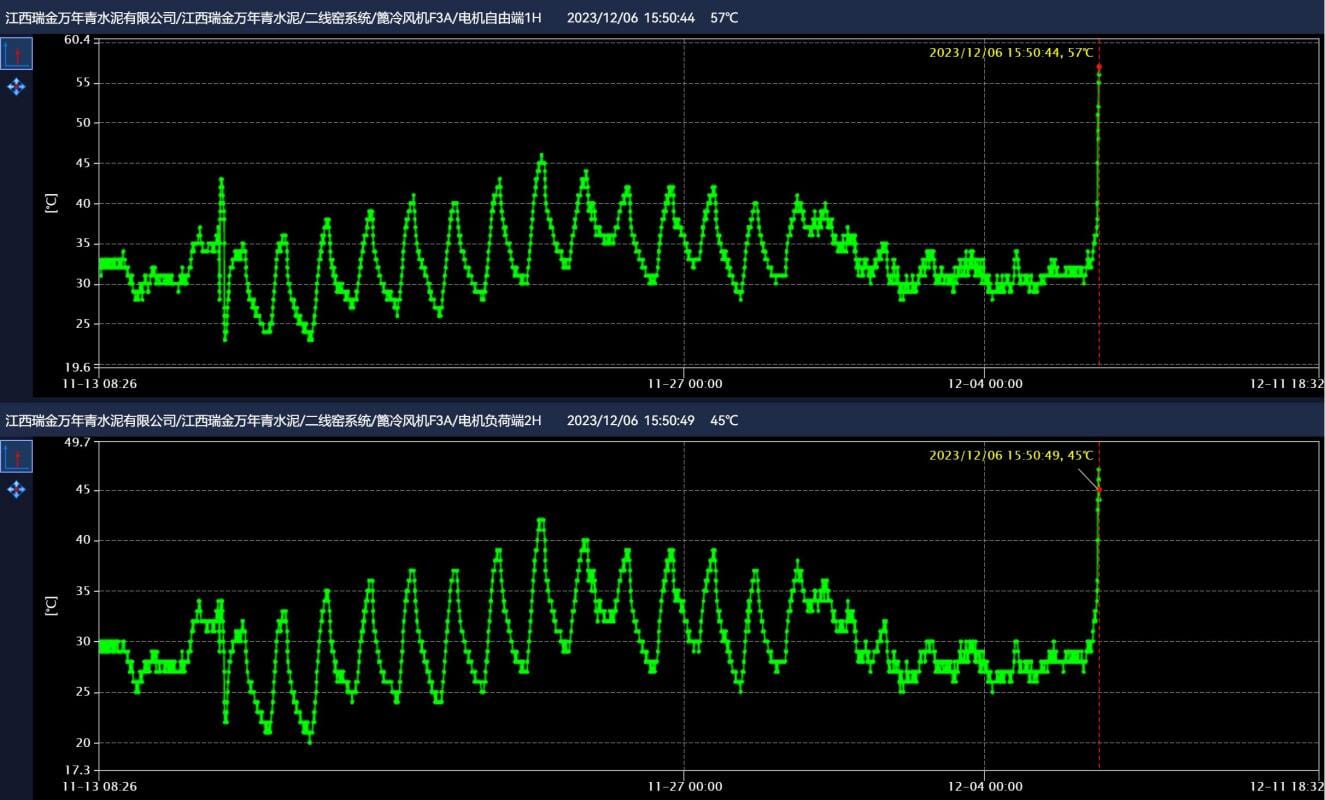

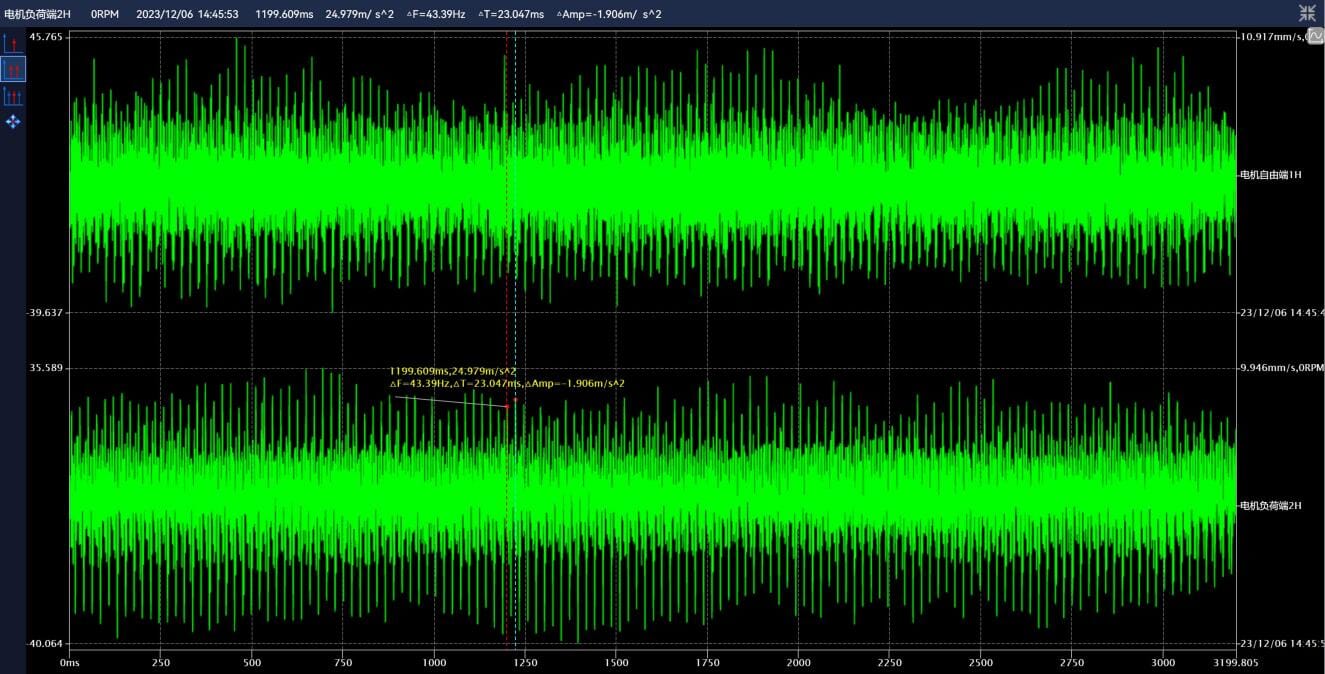

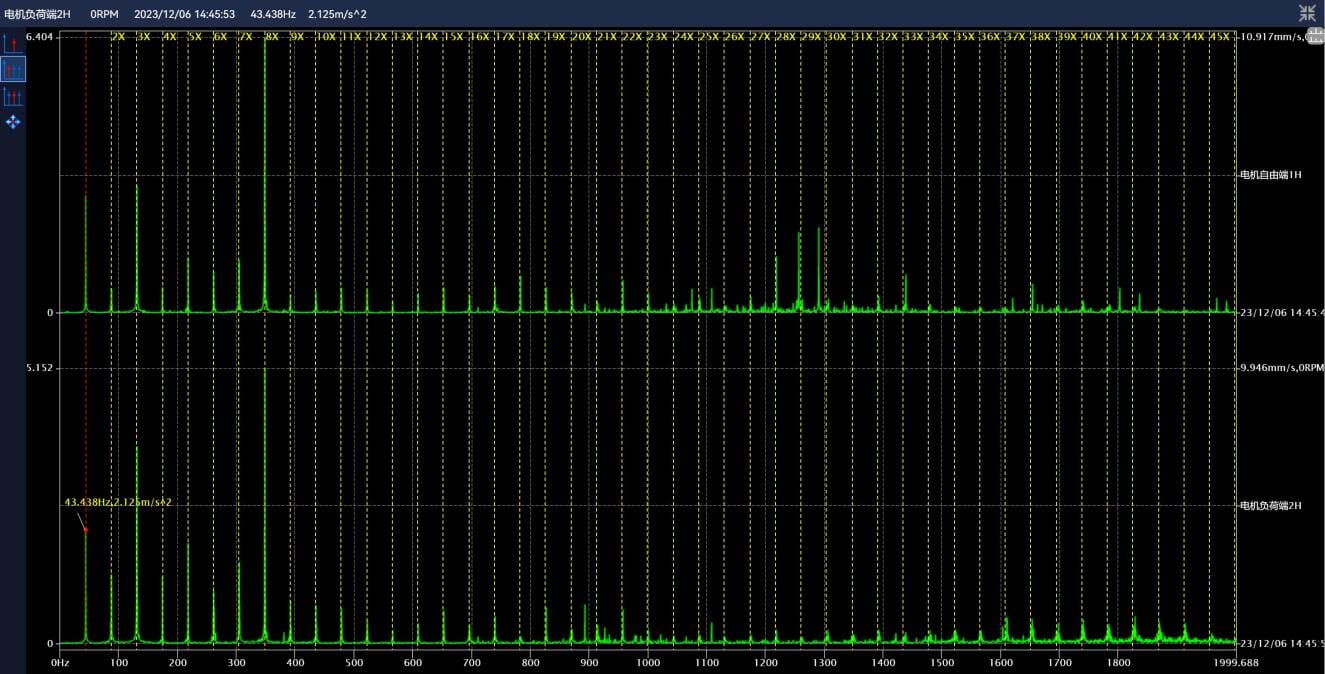

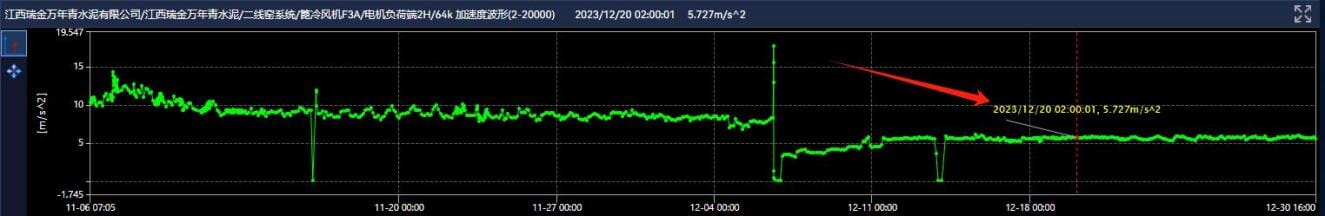

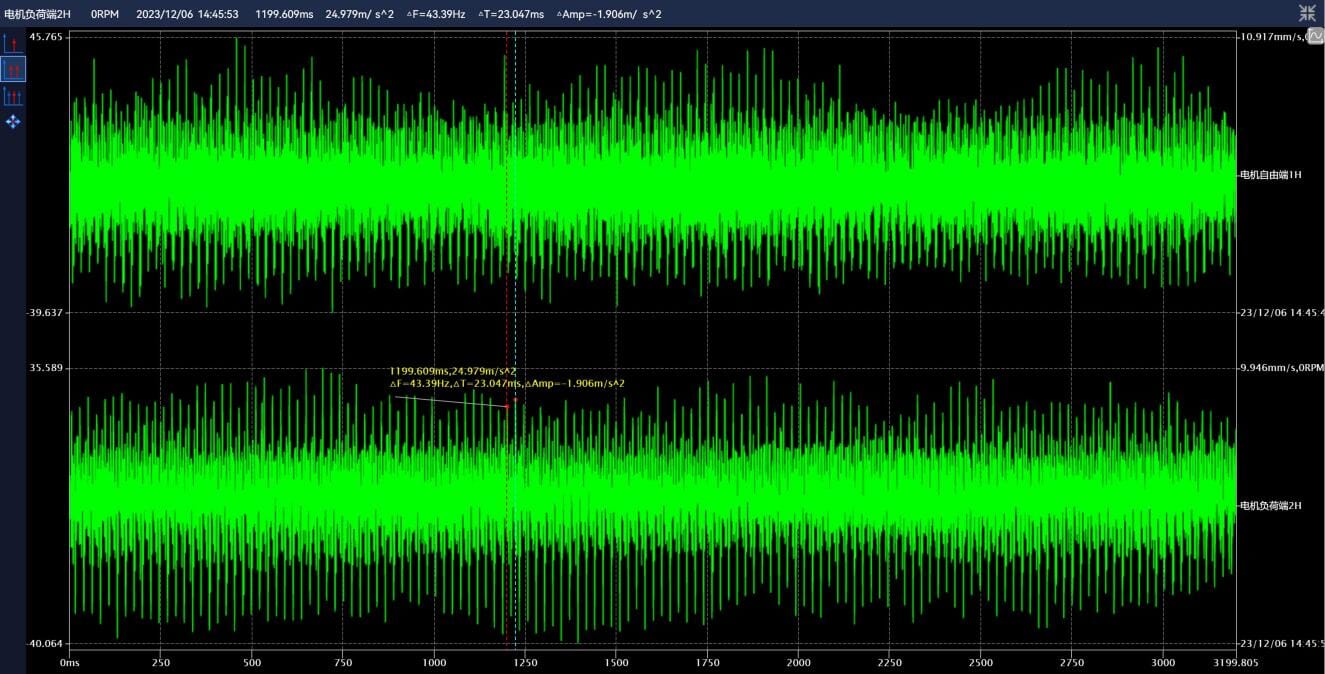

Jiangxi Ruijin Wannianqing Cement Grate Cooling Fan F3A

Jiangxi Ruijin Wannianqing Cement Grate Cooling Fan F3ALearn More

Start Your Journey to Intelligent Industrial Equipment Maintenance