Case Duration:

2016 - Present (9+ Years)

Client Background:

As a specialized special steel manufacturing group under CITIC Group and CITIC Pacific Ltd., CITIC Pacific Special Steel has become China’s leader in special steel production, market dominance, and industry standard-setting. The group operates “Ten Core Production Bases,” including six special steel manufacturing bases, two raw material supply bases, and two processing bases.

Client Background

As a specialized special steel manufacturing group under CITIC Group and CITIC Pacific Ltd., CITIC Pacific Special Steel has become China's leader in special steel production, market dominance, and industry standard-setting. The group operates "Ten Core Production Bases," including six special steel manufacturing bases, two raw material supply bases, and two processing bases.

Aligned with its 14th Five-Year Plan objectives, the Group aims to:

1. Achieve first-class domestic and partially world-class intelligent manufacturing standards;

2. Advance "Four Initiatives" in its intelligent, integrated, digital and networked development;

3. Strengthen "Three Centers": Data Center, Service Center, and Network Center

Client Requirements & Solutions

Comprehensive Intelligent O&M Solution for "1 Cloud + 4 Edge Centers + 10 Bases"

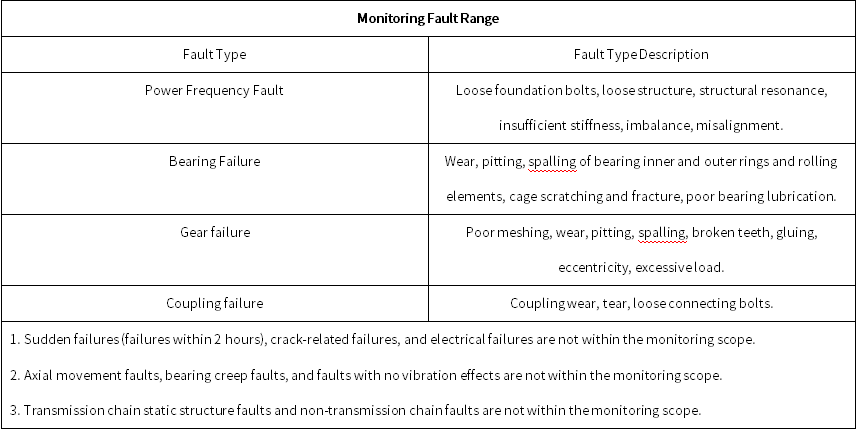

Equipment Intelligent Monitoring & Real-Time Status Control:

As of December 2024, equipment monitoring coverage across CITIC Pacific Special Steel bases includes:

1. Qingdao Special Steel: 860+ equipment units | 14,000 monitoring points

2. Daye Special Steel: 360+ equipment units | 4,400 monitoring points

3. Xingcheng Special Steel: 700+ equipment units | 8,300 monitoring points

4. Tianjin Steel Pipe: 160+ equipment units | 2,900 monitoring points

5. Nanjing Steel: 500+ equipment units | 5,900 monitoring points

6. Yangzhou Taifu: 60+ equipment units | 800 monitoring points

7. Other bases: 50+ equipment units | 500+ monitoring points

Integrated Platform, Expert System & Standardization:

Focused on four core centers (Xingcheng, Qingdao, Daye, Tianjin), RONDS assisted in building:

1. An intelligent O&M platform (condition monitoring + equipment management)

2. Diagnostic centers + expert teams

3. Unified work models, process standards, and system interfaces

Application Value

Innovative "1 Cloud + 4 Edge Centers + 10 Bases" Model:

1. Established four intelligent O&M centers (Xingcheng, Qingdao, Daye, Tianjin) with localized platforms

2. Implemented group-level oversight platform for key performance indicator management

Zero-Accident Operations & Cost Reduction:

At Qingdao Special Steel since 2020 system launch:

1. Zero unplanned downtime incidents for critical host equipment

2. Annual savings: CNY 9M+ in emergency repair costs

3. Additional CNY 6M/year production value from increased uptime

4. Total annual benefit: CNY 15M+

Knowledge Accumulation & O&M Innovation:

1. Developed independent equipment monitoring/diagnosis capabilities with in-house expert teams

2. Created equipment lifespan prediction curves for precision maintenance planning

3. Built a group-wide failure case database for talent development and advanced applications

Supporting Xingcheng Special Steel's Lighthouse Network Achievement:

RONDS' intelligent equipment management system became a key component in Xingcheng Special Steel's successful bid for the world's first special steel Lighthouse Network designation, earning unanimous approval from the WEF evaluation panel.

Success Cases

-

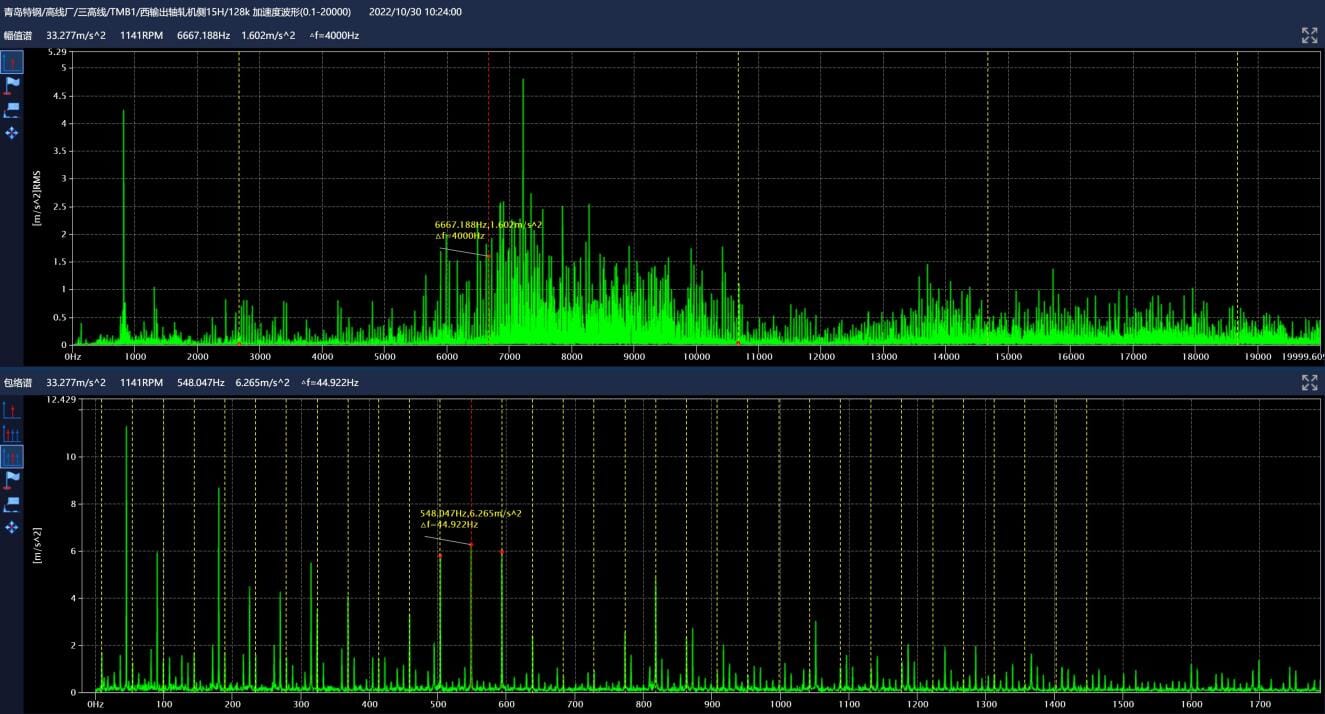

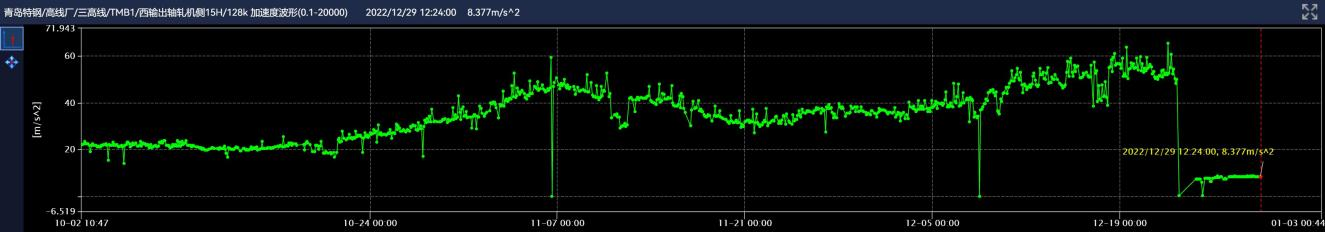

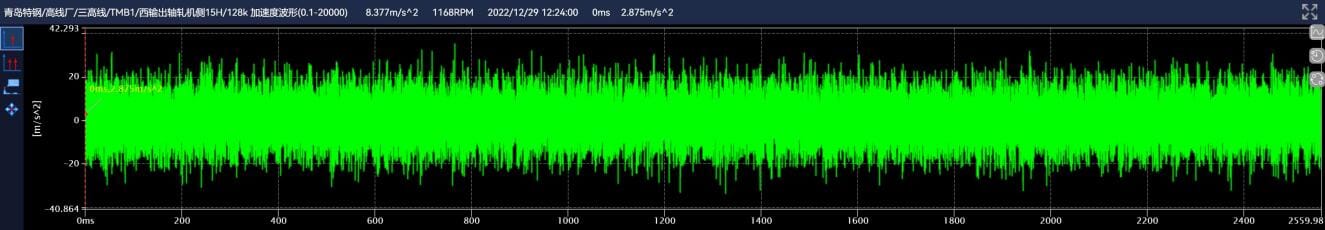

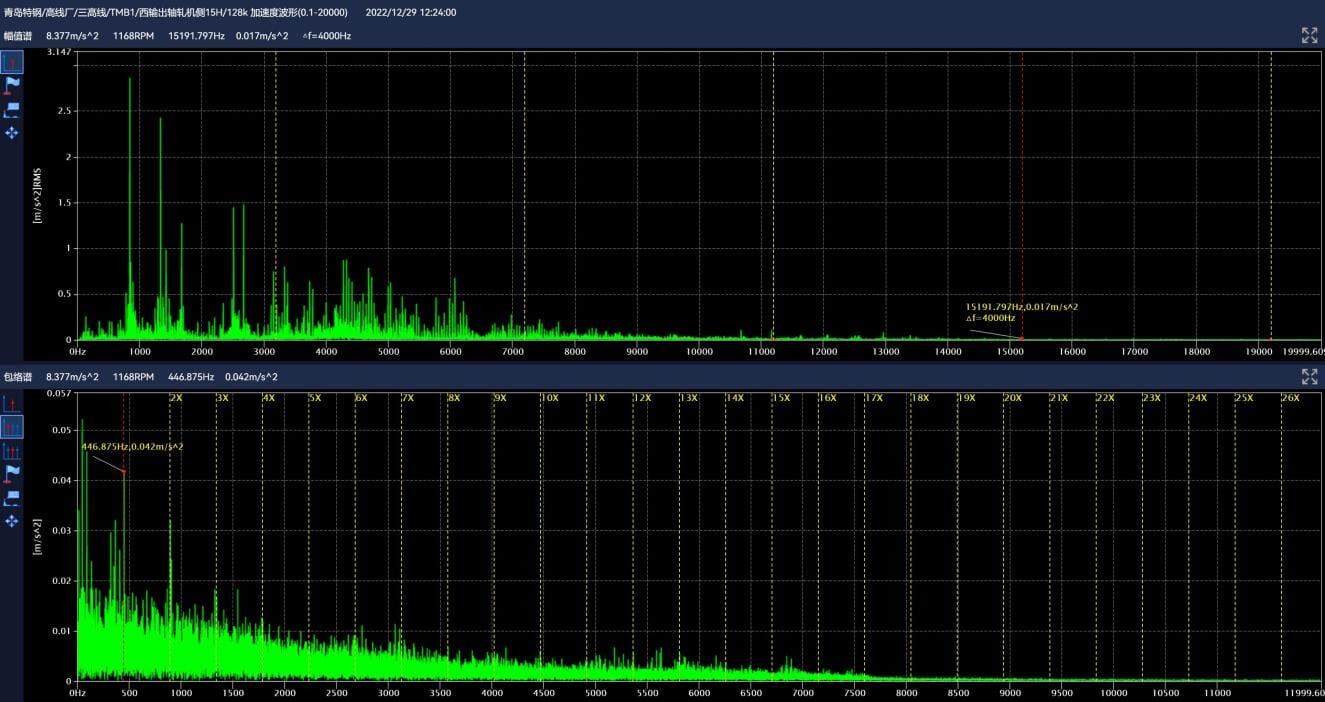

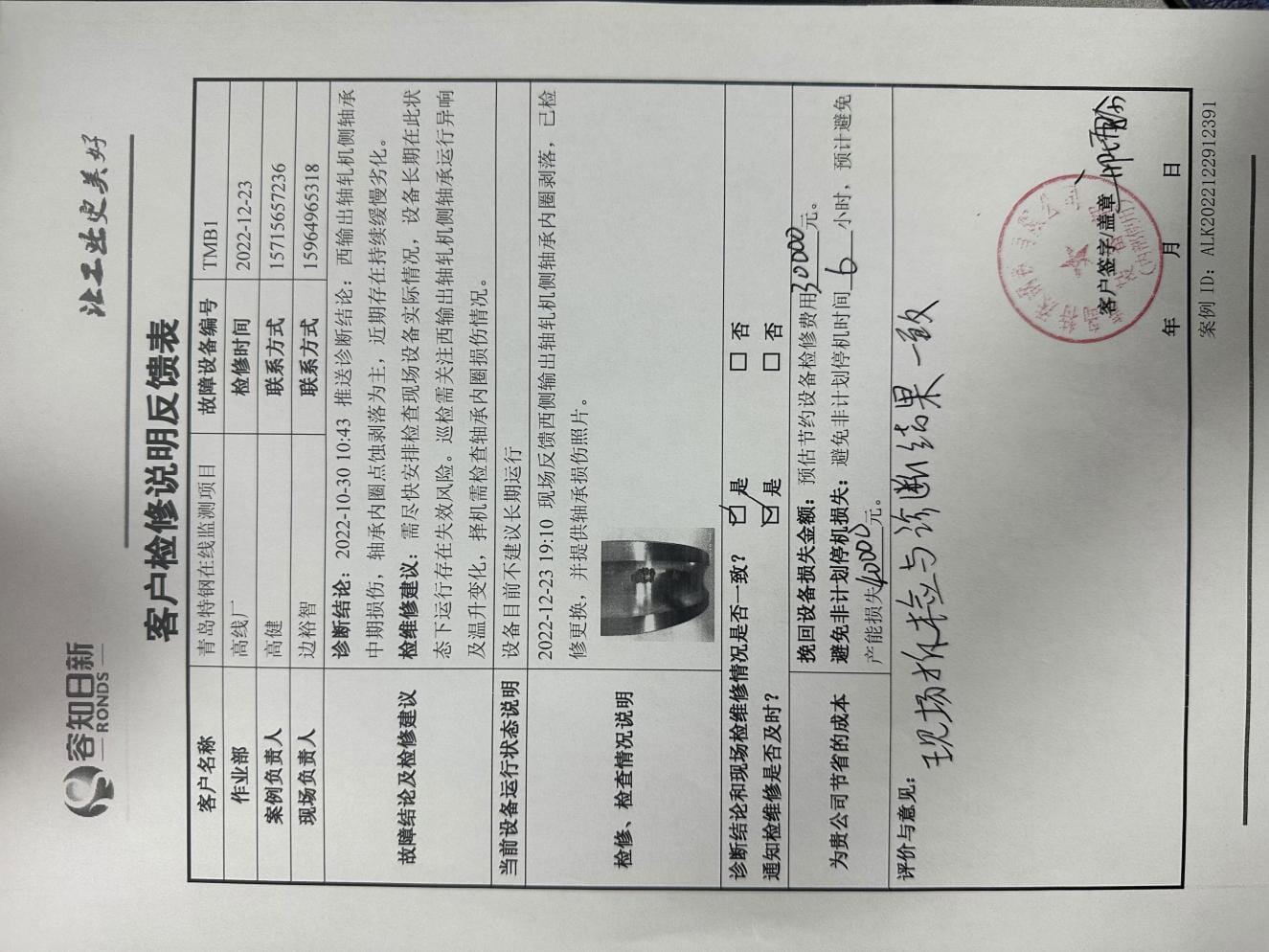

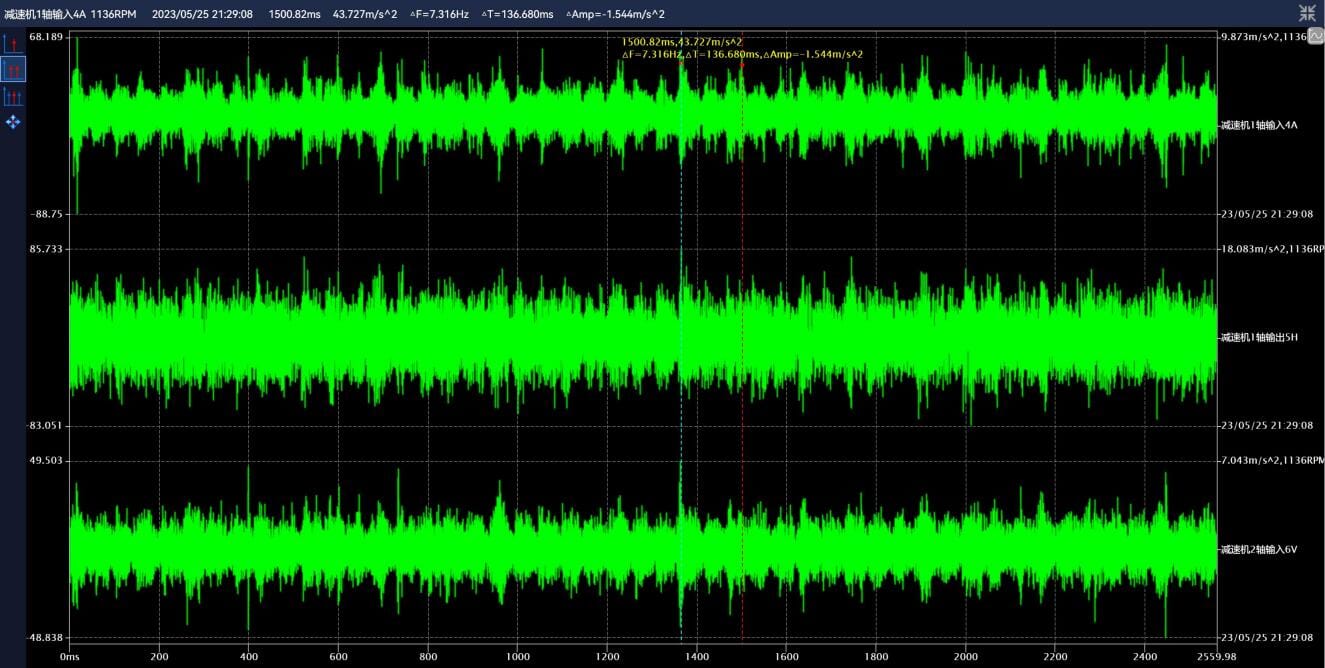

Qingdao Special Steel Co.,Ltd. Online Monitoring Project TMB1

Qingdao Special Steel Co.,Ltd. Online Monitoring Project TMB1Learn More

-

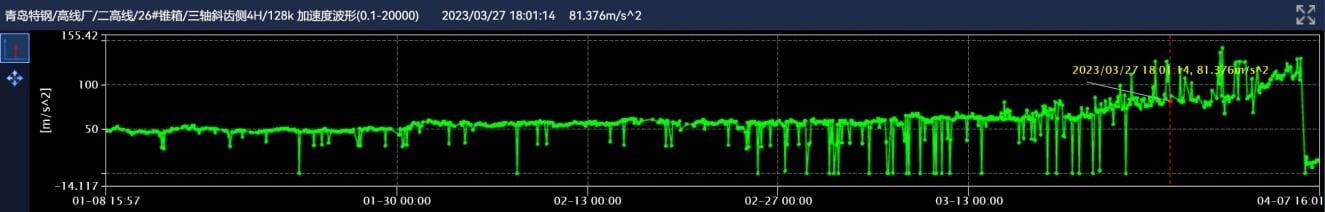

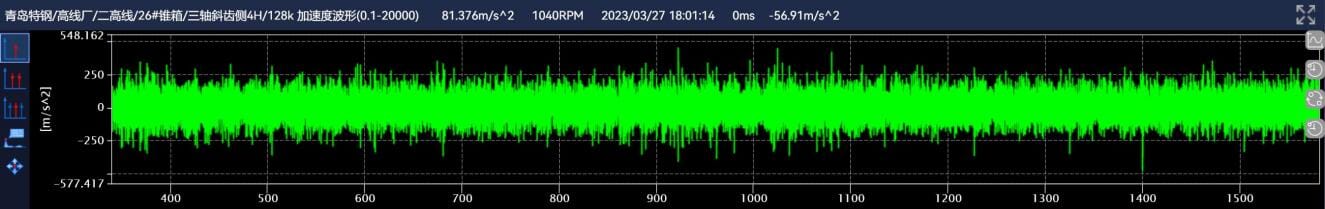

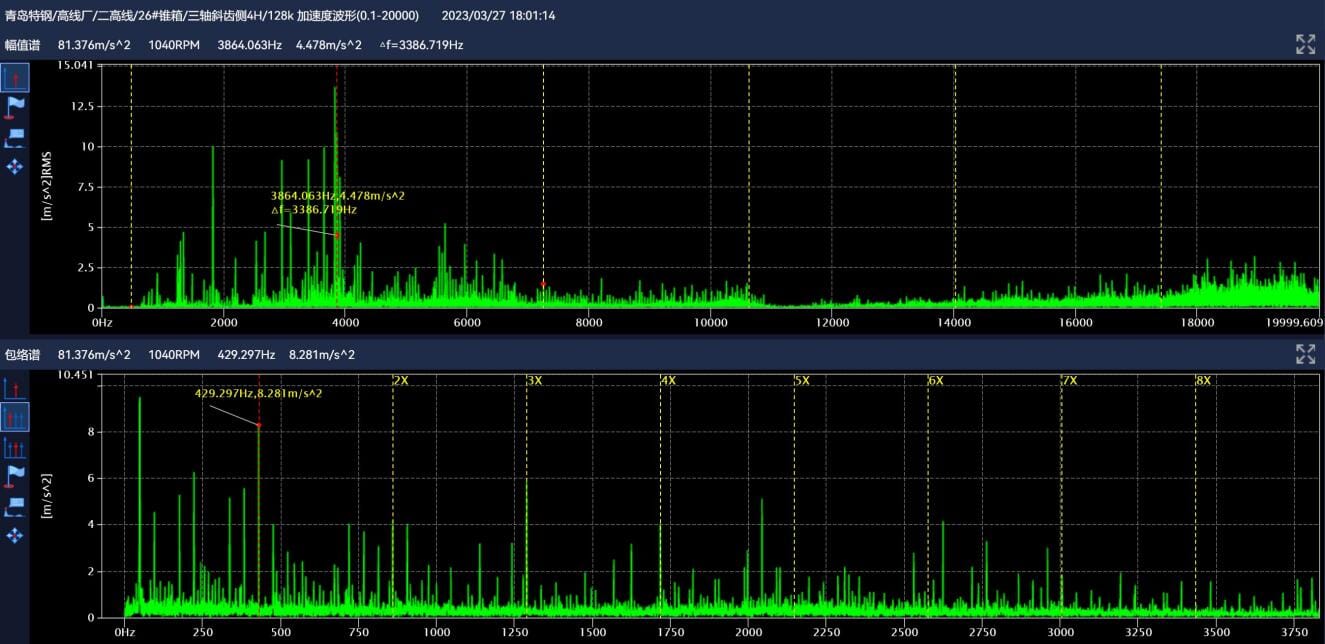

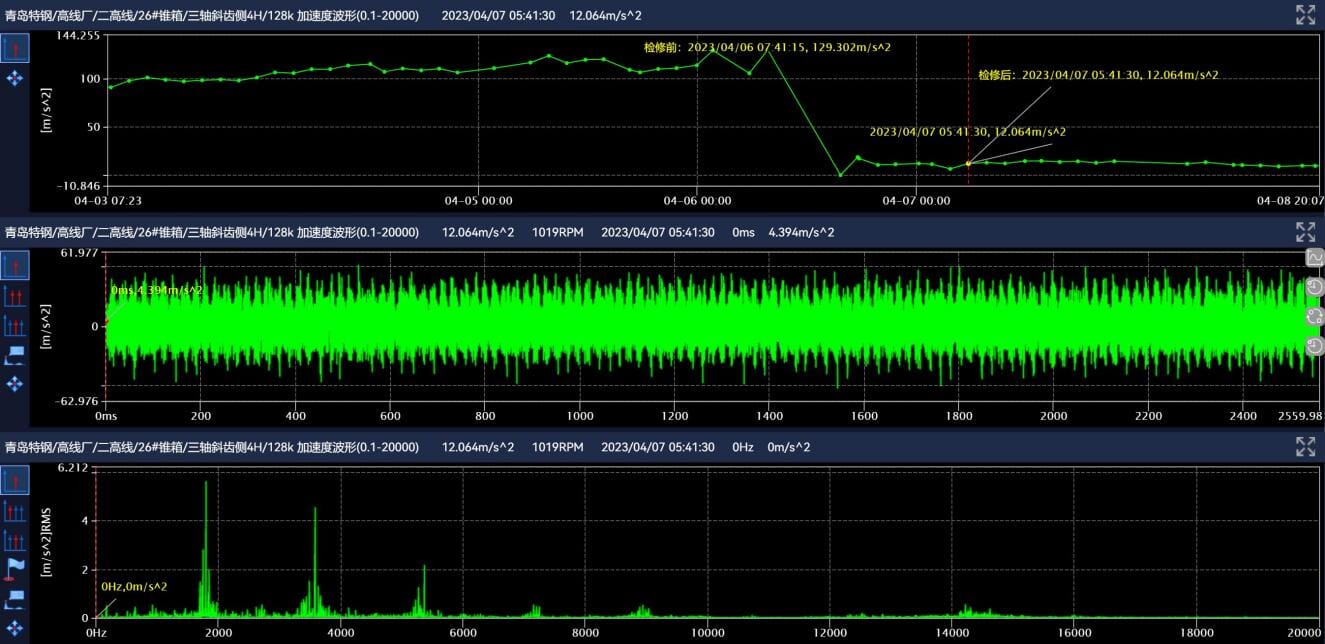

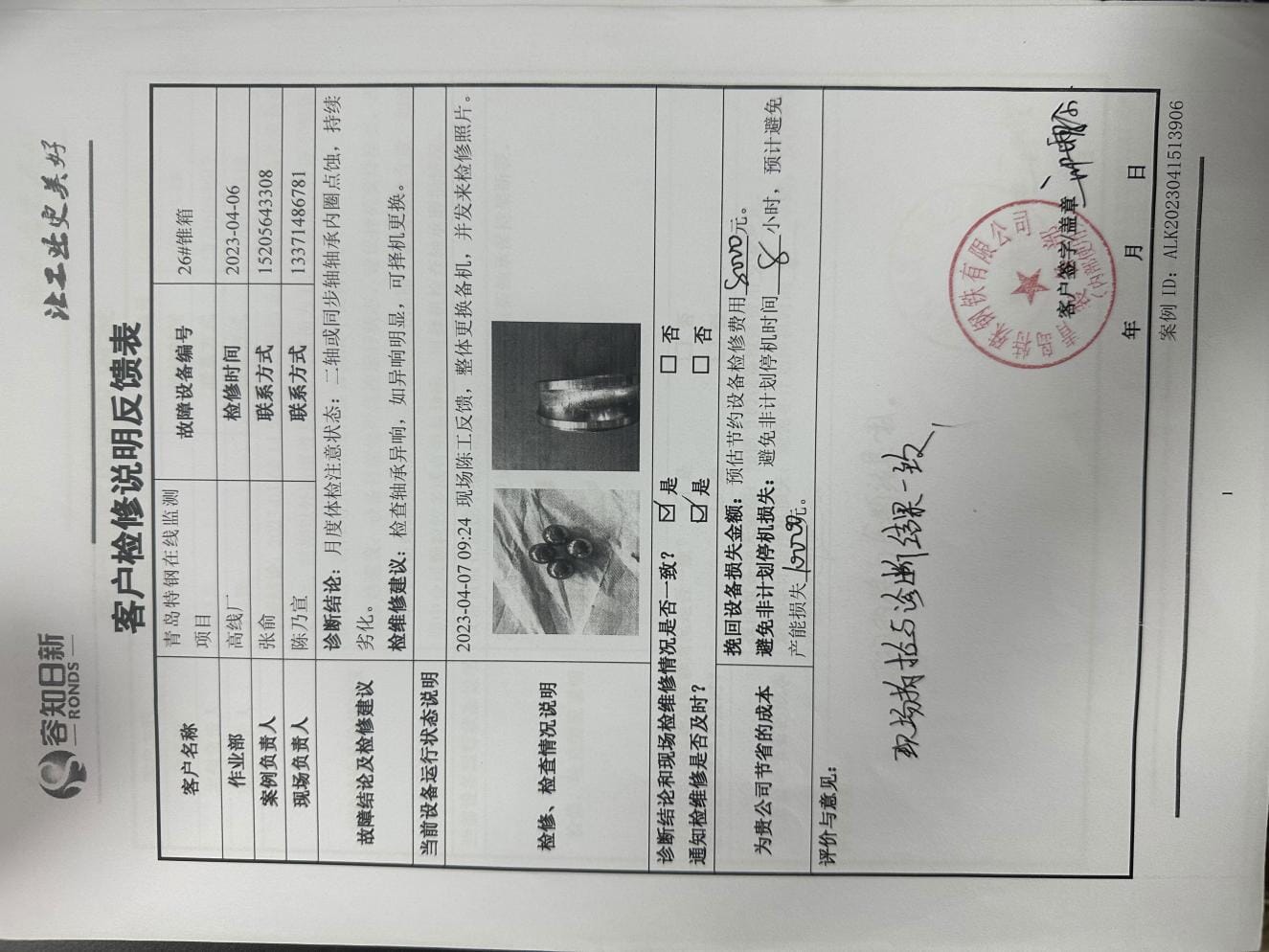

Qingdao Special Steel Co.,Ltd. Online Monitoring Project 26# Cone Box

Qingdao Special Steel Co.,Ltd. Online Monitoring Project 26# Cone BoxLearn More

-

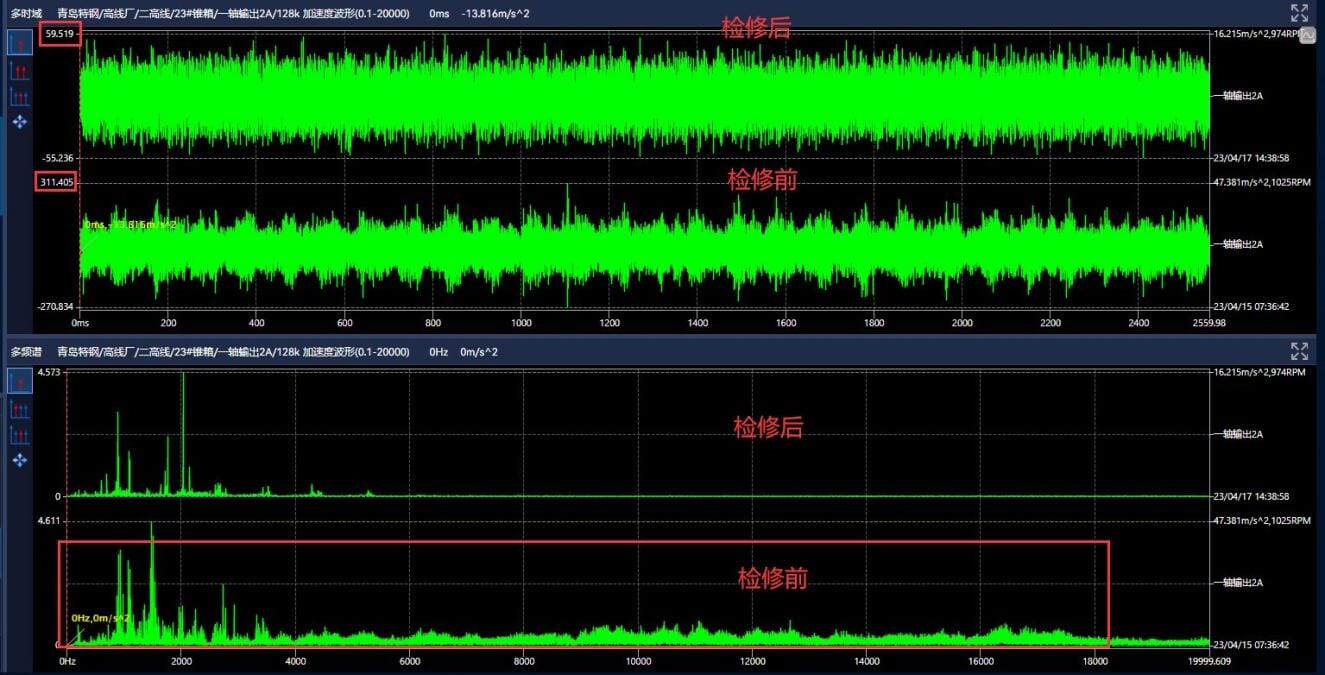

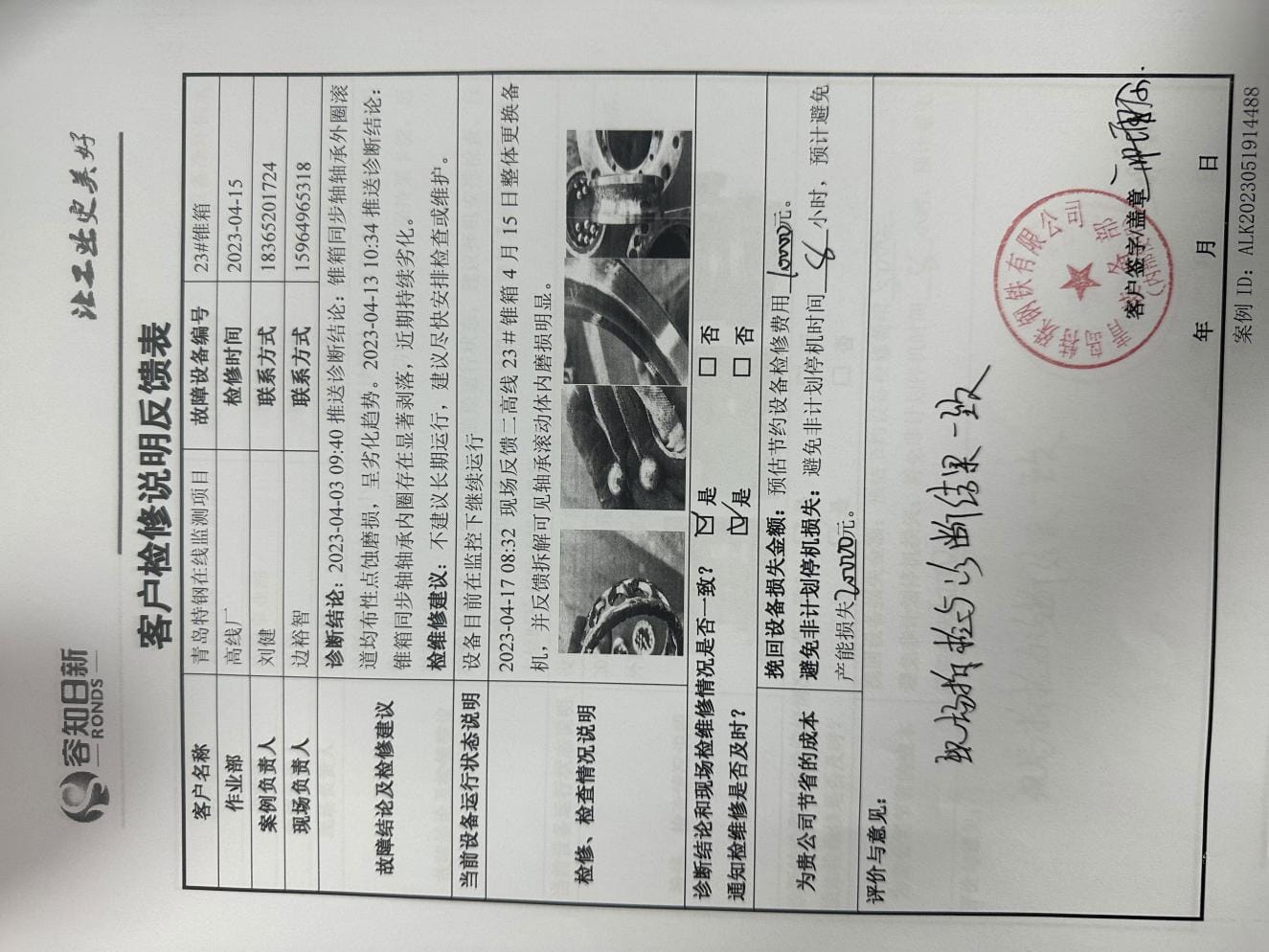

Qingdao Special Steel Co.,Ltd. Online Monitoring Project 23# Cone Box

Qingdao Special Steel Co.,Ltd. Online Monitoring Project 23# Cone BoxLearn More

-

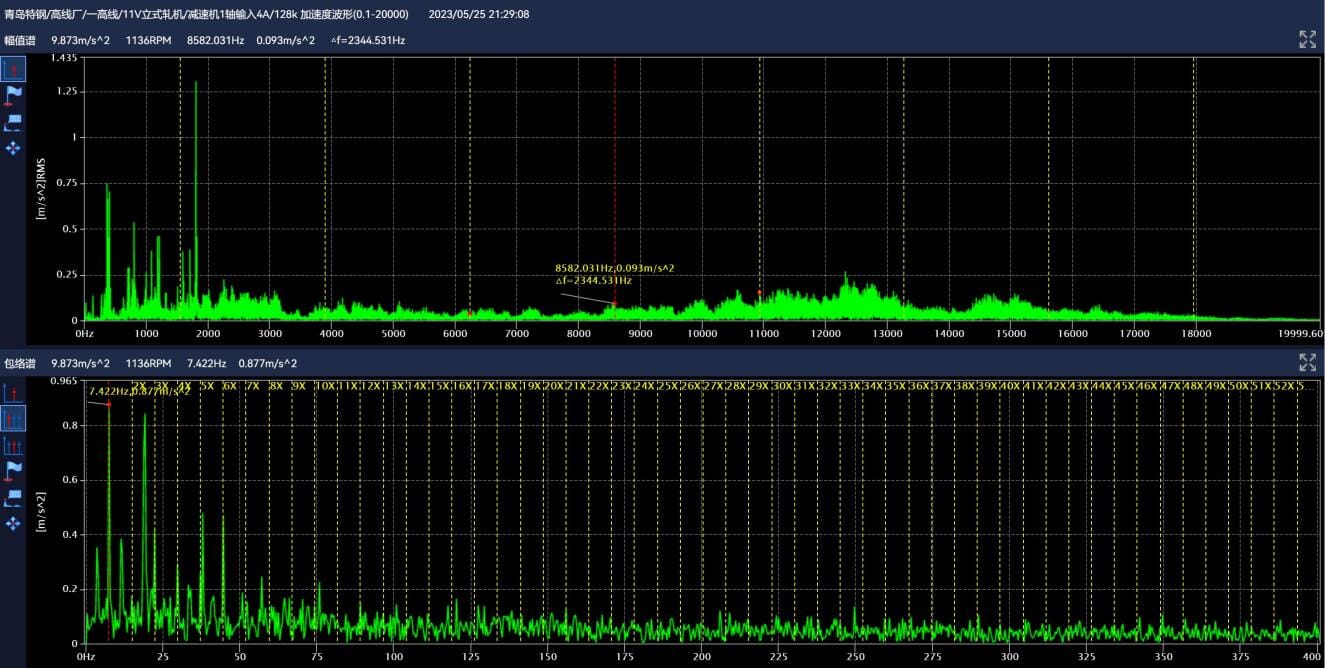

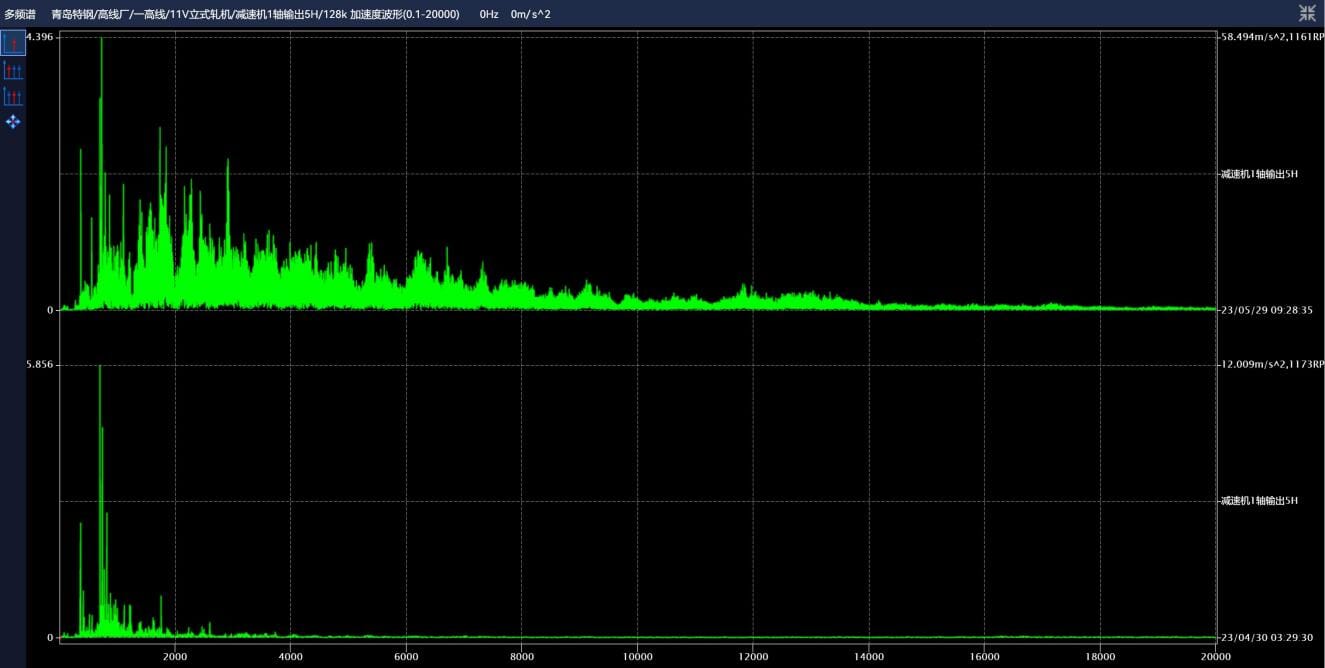

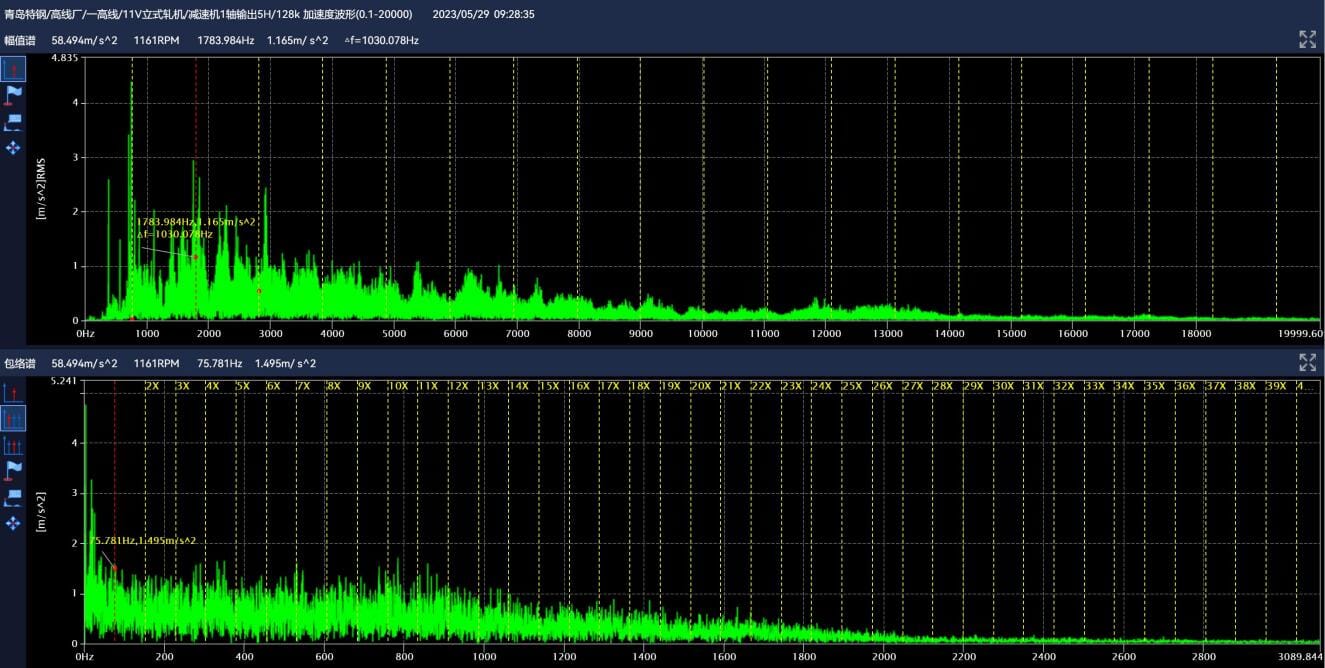

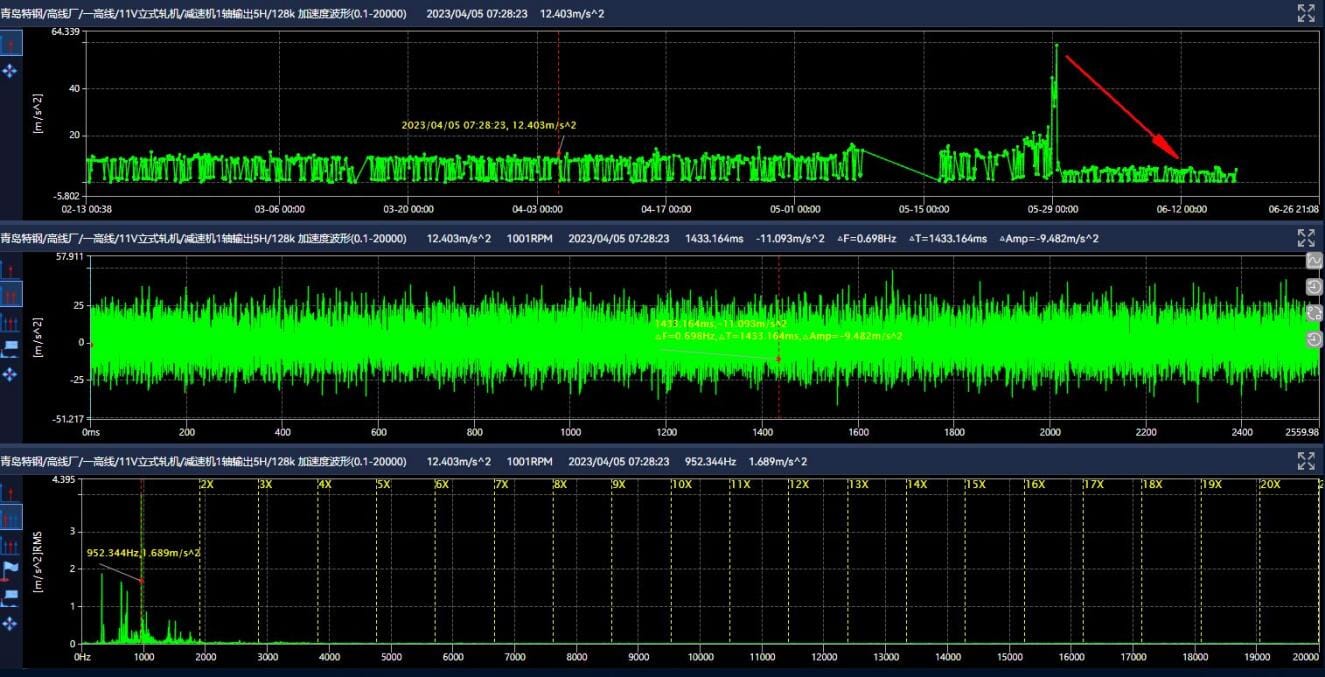

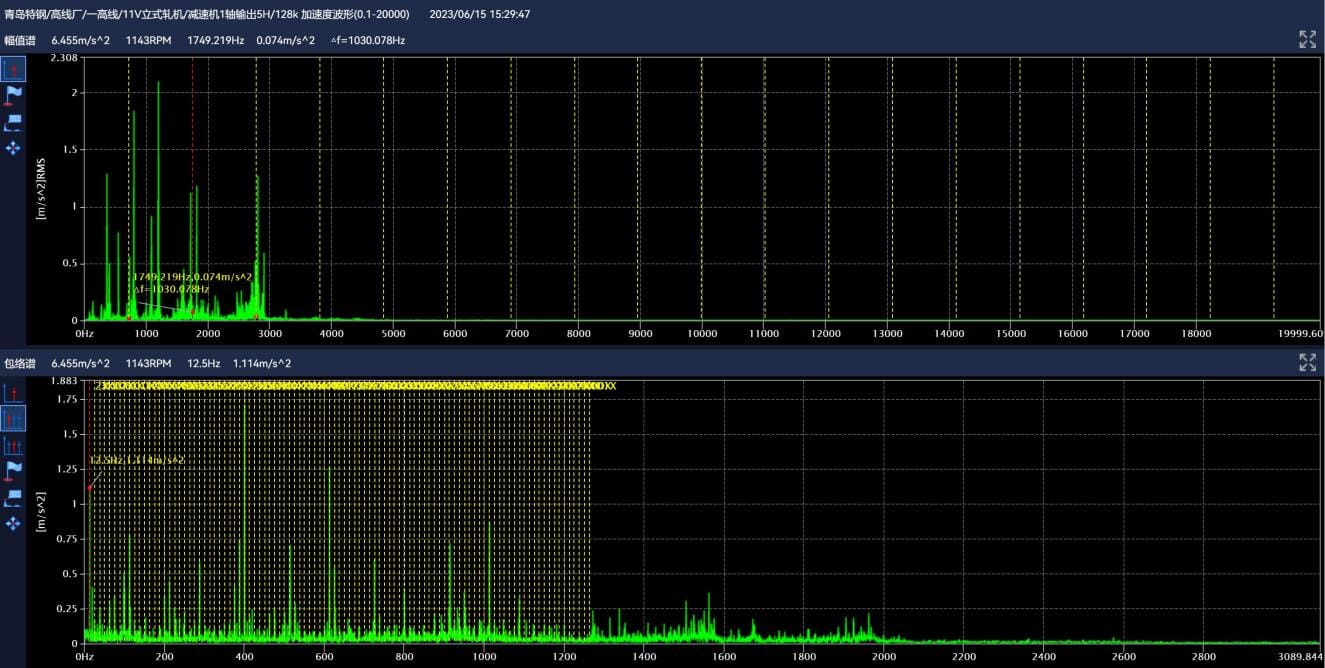

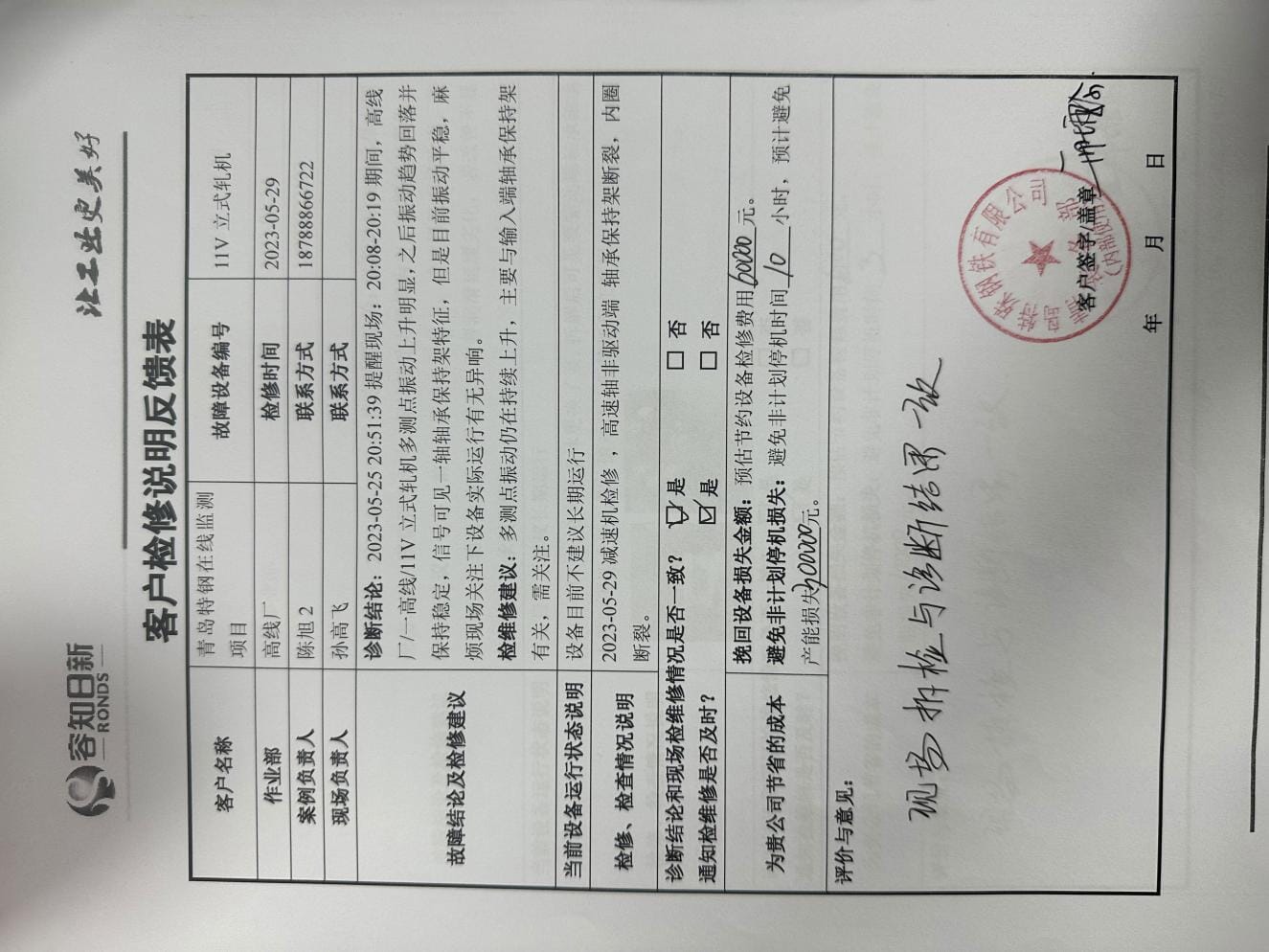

Qingdao Special Steel Co.,Ltd. Online Monitoring Project 11V Vertical Rolling Mill

Qingdao Special Steel Co.,Ltd. Online Monitoring Project 11V Vertical Rolling MillLearn More

Start Your Journey to Intelligent Industrial Equipment Maintenance