Case Duration:

2019 - Present (6+ Years)

Client Background:

As a central state-owned enterprise directly administered by China's central government, China Baowu was designated by SASAC in 2020 as a national model for world-class enterprise development. Key 2023 metrics: Total assets: 1.36 trillion yuan、Steel output: 130 million tons、Revenue: 1.11 trillion yuan、Ranked #44 on 2024 Fortune Global 500 (top global steel producer)

Client Requirements & Solutions

Assist Baowu in its intelligent equipment management, driving business processes and improving management efficiency

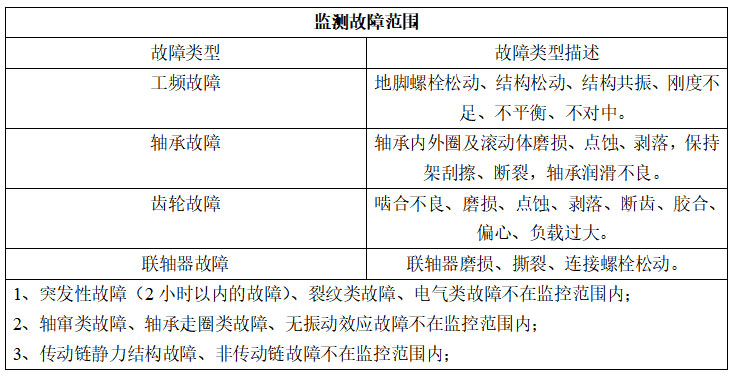

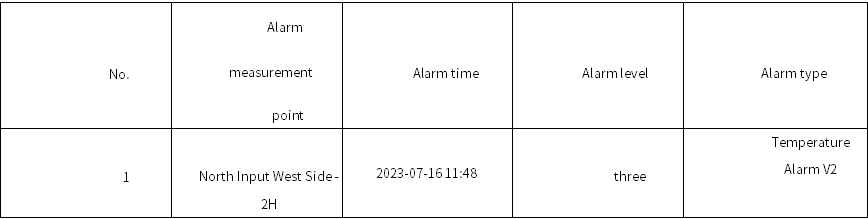

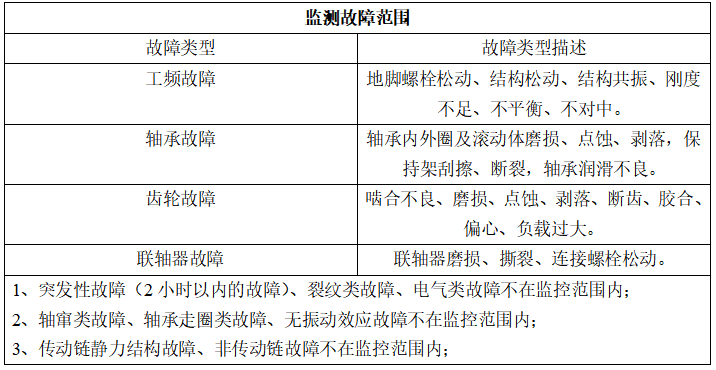

Predictive Maintenance Through Real-Time Equipment Monitoring:

1. Deployed smart monitoring systems across Baowu's production bases for critical assets (fans, pumps, rolling mills)

2. Enabled edge computing and platform integration to support Baowu's intelligent O&M platform

3. Achieved early fault prediction capability

Big Data and Intelligent Algorithm Services:

The customer sought to leverage RONDS' extensive expertise in industrial big data processing and intelligent algorithm development, along with its rich case library, combined with Baowu's on-site specialist knowledge in Intelligent O&M, to develop and iterate intelligent algorithms. RONDS supported the deployment of algorithms on the Baowu's intelligent O&M platform and engaged in in-depth collaboration on the development and iteration of intelligent algorithms to enhance the level of equipment management intelligence.

Driving Business Processes and Improving Management Efficiency:

Experts from both parties collaborated to address industry monitoring challenges and pain points, jointly designing specialized scenario solutions and developing smart hardware for specific applications.

Simultaneously, RONDS integrated data from on-site intelligent monitoring systems with the Baowu's intelligent O&M platform. By applying intelligent algorithm models, quantified results were generated to support business management and decision-making, providing effective support for China Baowu's remote operations, business-driven processes, and analytical decision-making.

Application Value

Full Coverage Across 60+ Production Lines at China Baowu:

Real-time online monitoring implemented across 60+ production lines at:

Ma'anshan Steel Plant

Taiyuan Steel Plant

Shaoguan Steel Plant

Chongqing Steel Plant

Kunming Steel Plant

Comprehensive Monitoring of Critical Equipment for Efficiency Improvement:

• Nearly 12,000+ key equipment units covered across:

1) Iron-making processes

2) Steel-making processes

3) Rolling processes

• Cloud-based data integration achieved

• Significant reduction in equipment failure rates

• Demonstrated production efficiency gains

1. Baoshan Base - Dedicated Smart O&M for Fan Systems

1) 90.8% accuracy rate for system alerts and diagnostics

2) Zero environmental compliance incidents caused by dust removal fan failures

3) 45% reduction in routine inspection workload

4) 25.6% decrease in maintenance workload

2. Songshan Base - Smart O&M for High-Speed Wire Rod Production Line

1) 84 accurate early warnings issued (preventing 12 major failures)

2) 132 hours of unplanned downtime avoided

3) 13,000 tons of production capacity preserved

4) 1 million yuan reduction in equipment maintenance costs

3. Ma'anshan Base - 2250 Hot Rolling Production Line

1) Integrated "Inspection + Maintenance + Spares + Materials" management system

2) 20% improvement in overall equipment condition

3) 10% reduction in per-ton steel production costs (full-cost basis)

4) 500,000-ton additional production capacity secured

Accelerating Baowu's Intelligent Equipment Management Transformation:

1. Enhanced smart O&M system through:

1) Online monitoring solutions

2) Intelligent algorithm deployment

2. Advanced China Baowu's equipment management intelligence through:

1) Digital transformation initiatives

2) Predictive maintenance capabilities

Success Cases

-

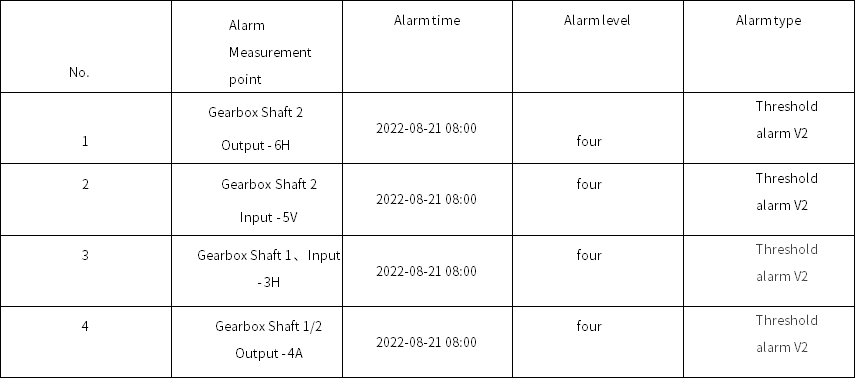

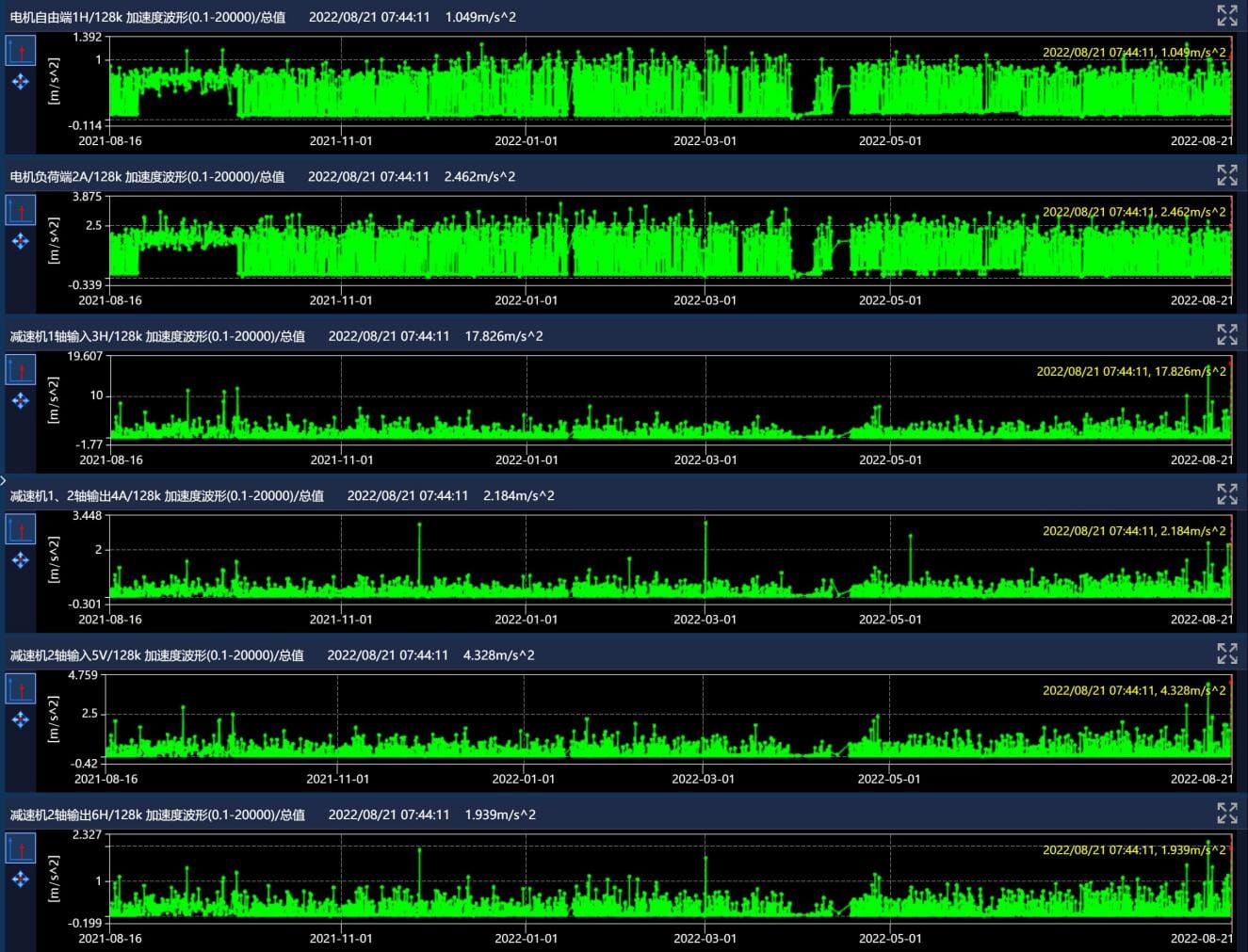

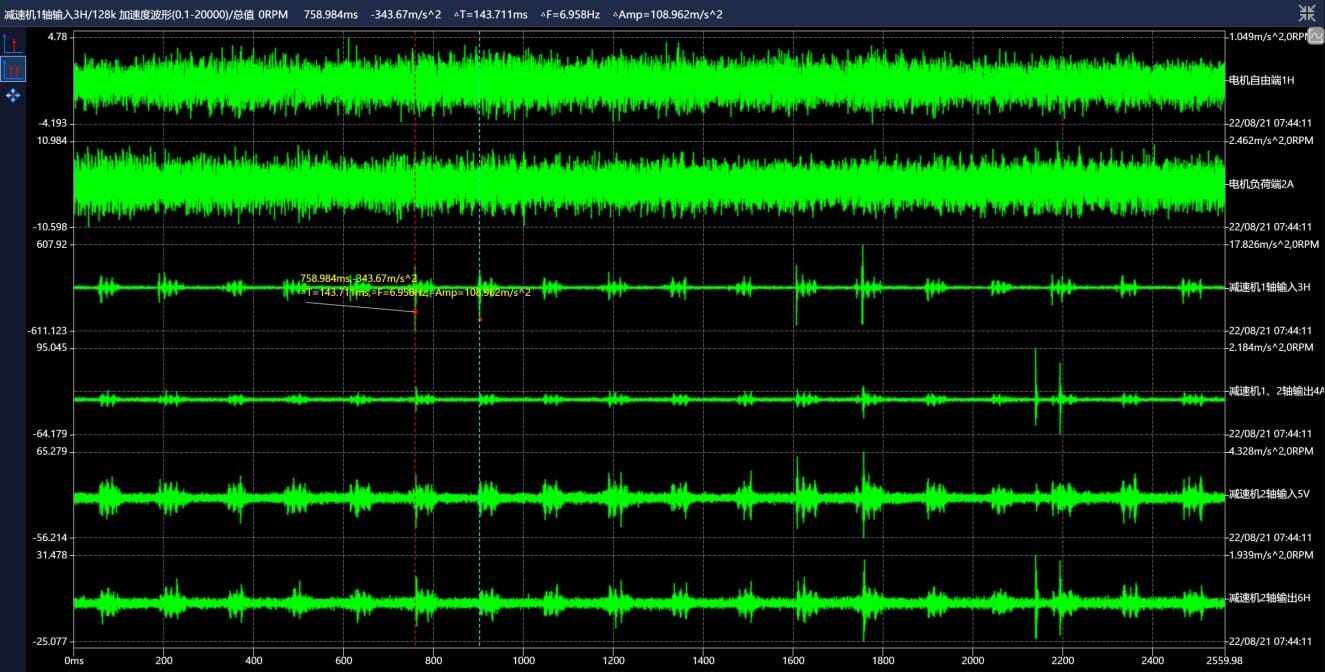

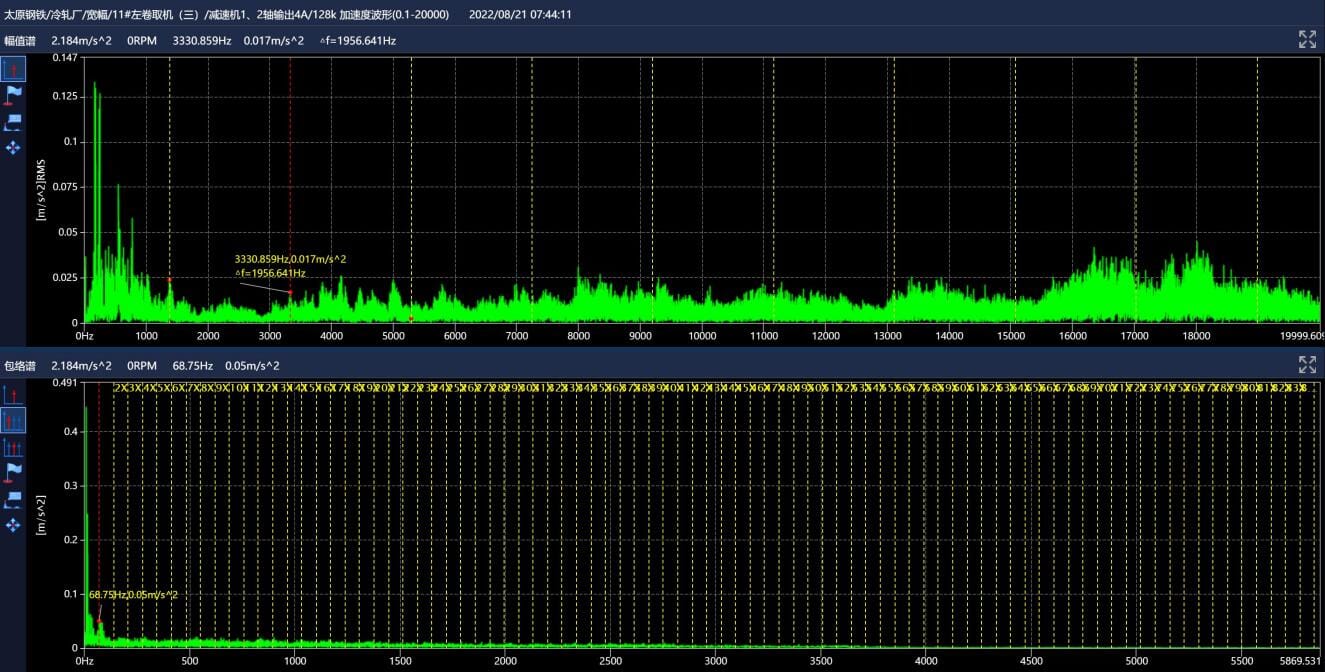

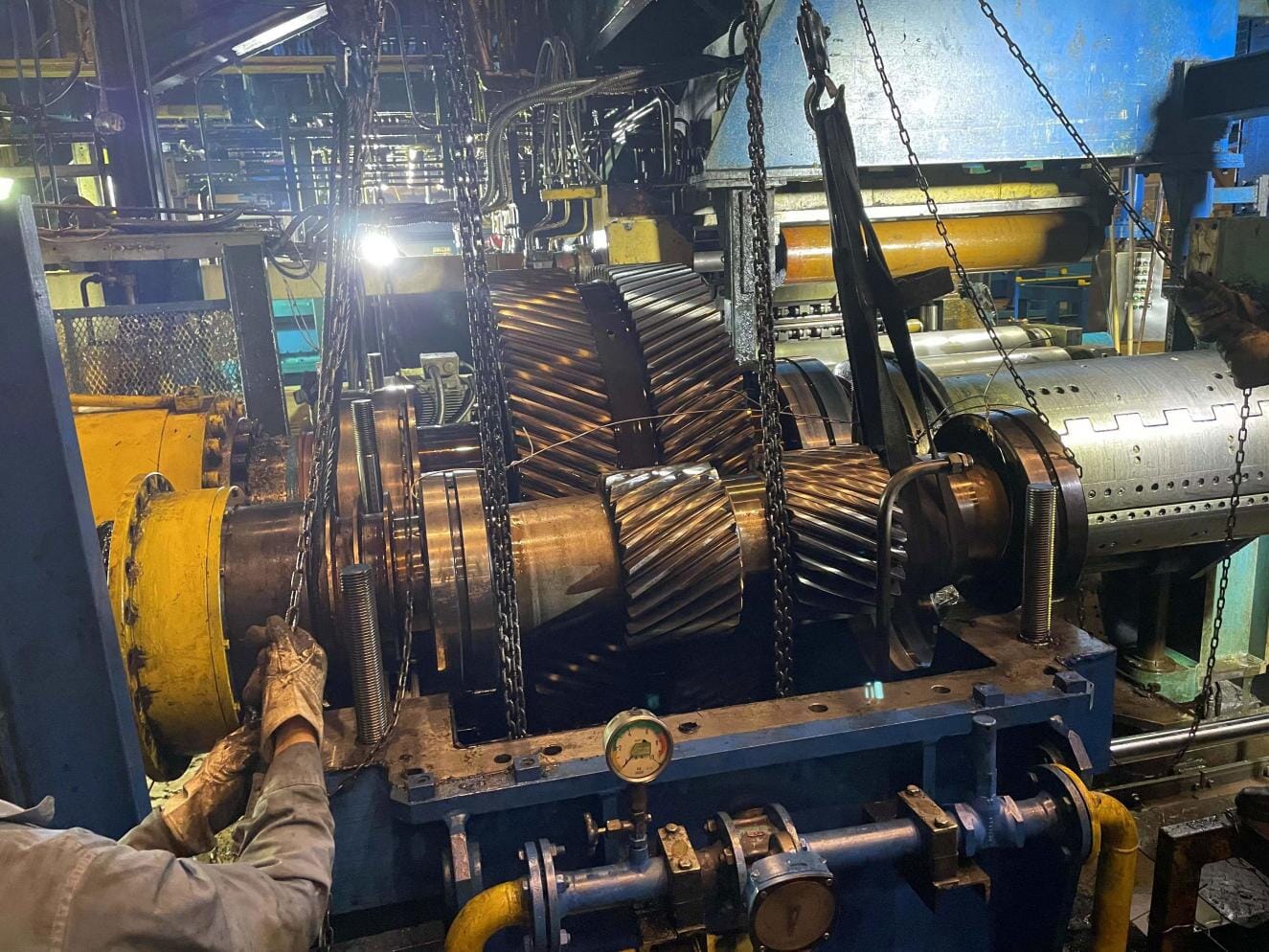

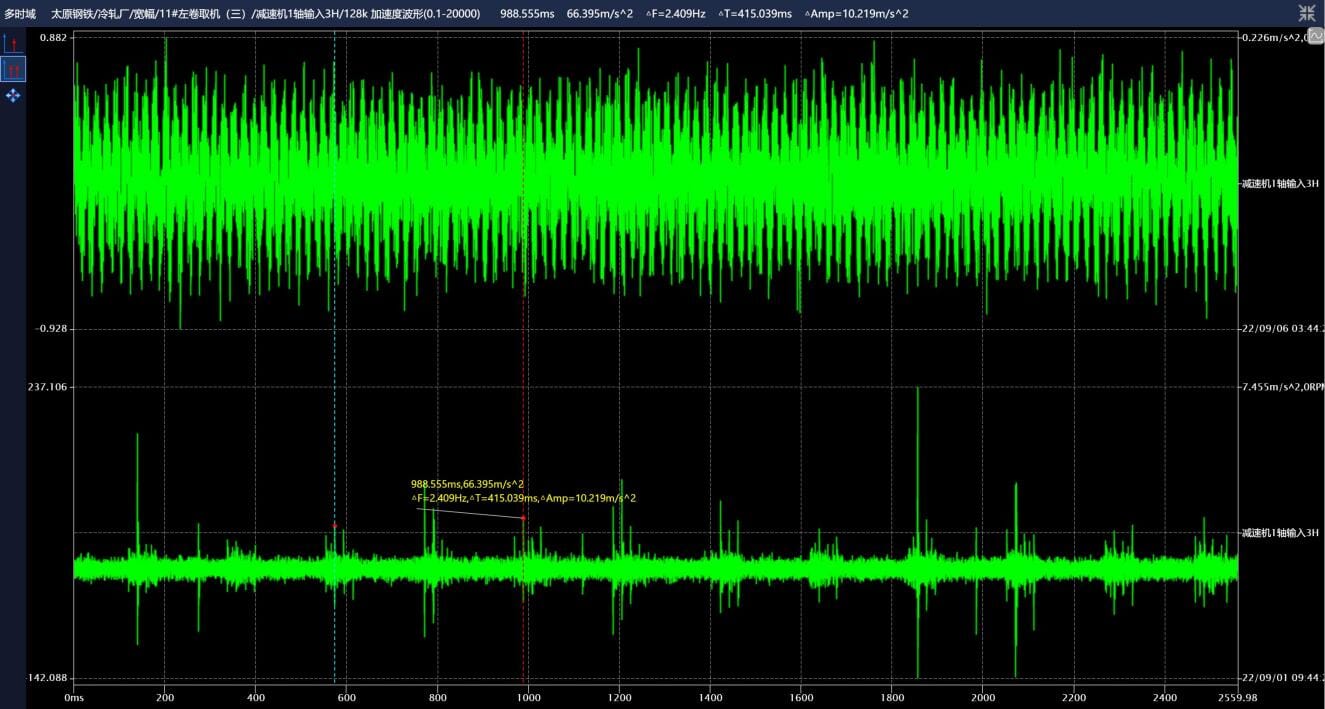

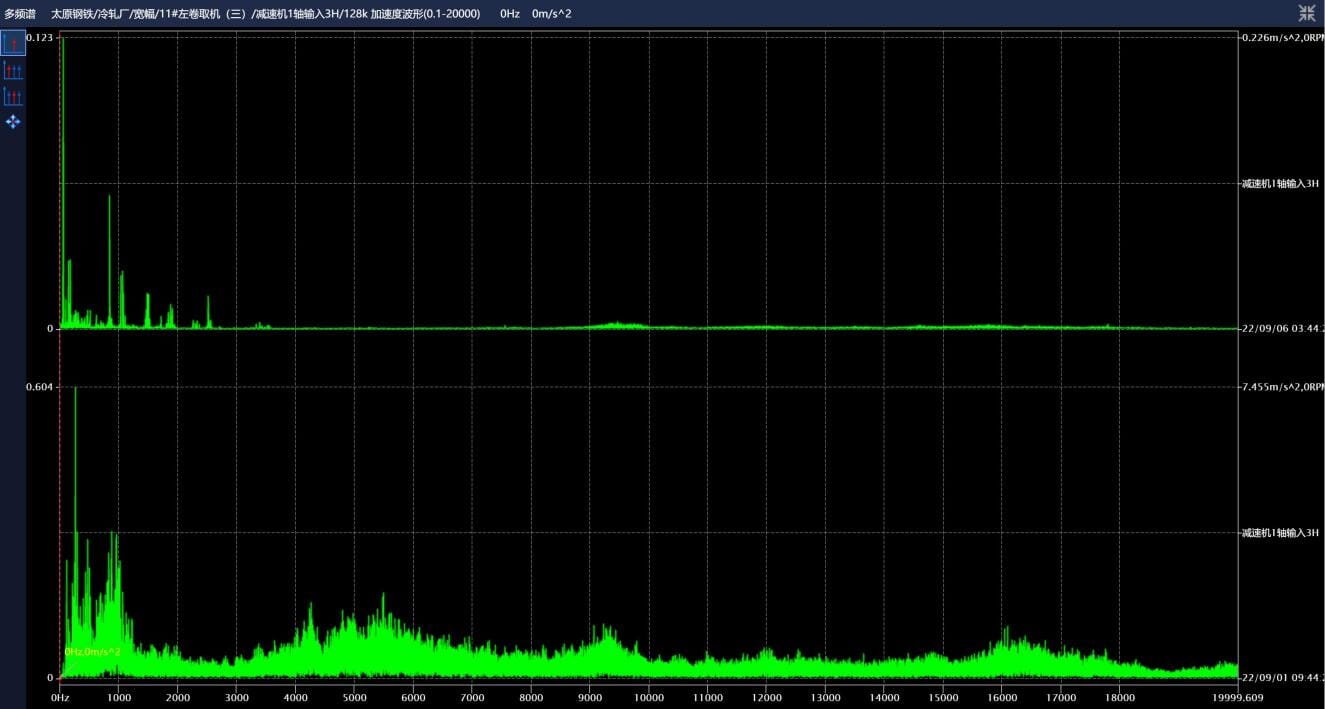

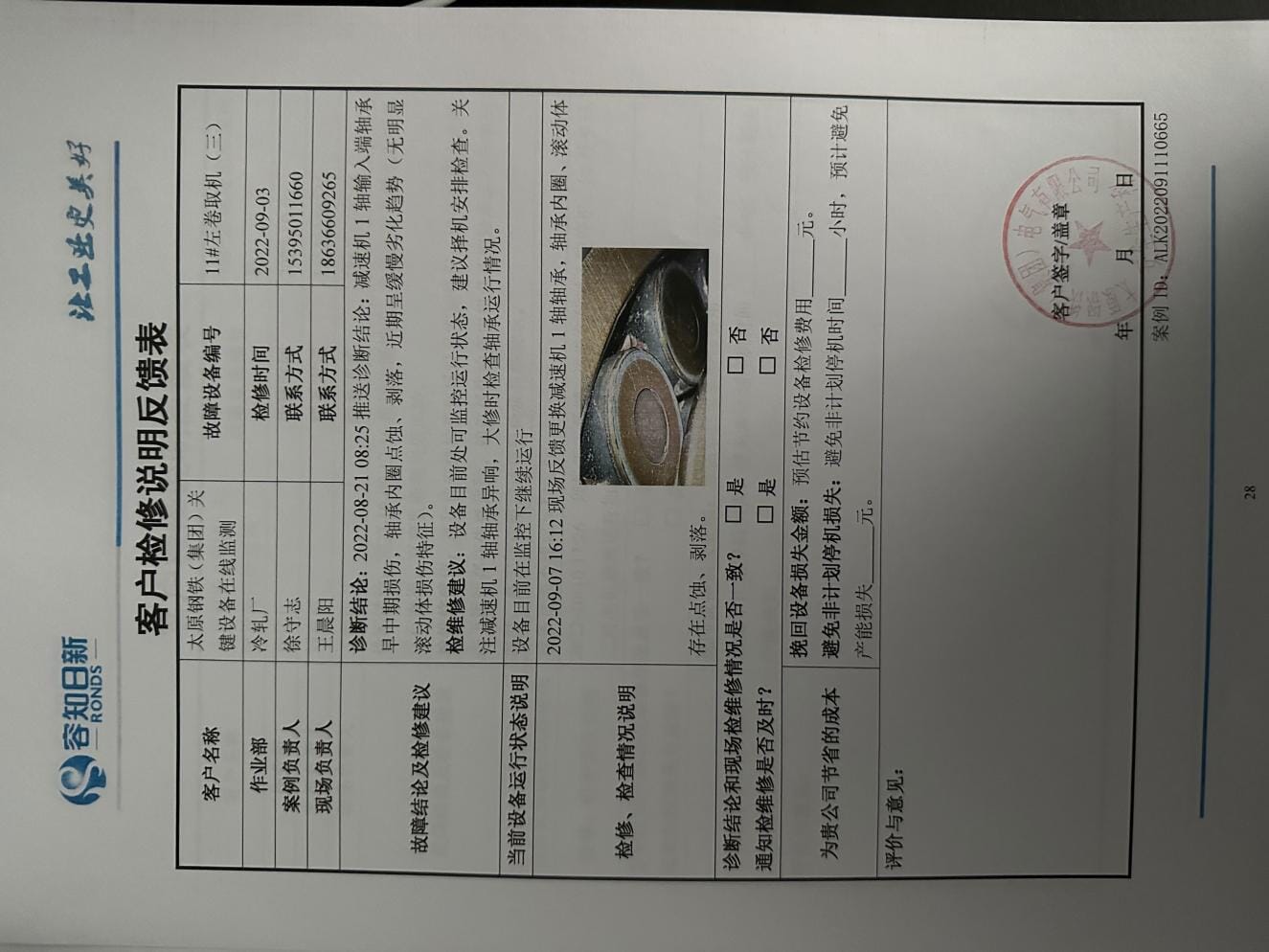

Taiyuan Iron & Steel Group Co., Ltd. #11 Left Coiler (3)

Taiyuan Iron & Steel Group Co., Ltd. #11 Left Coiler (3)Learn More

-

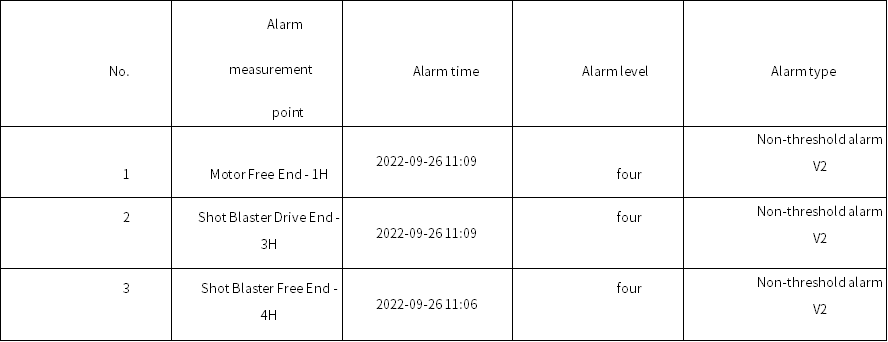

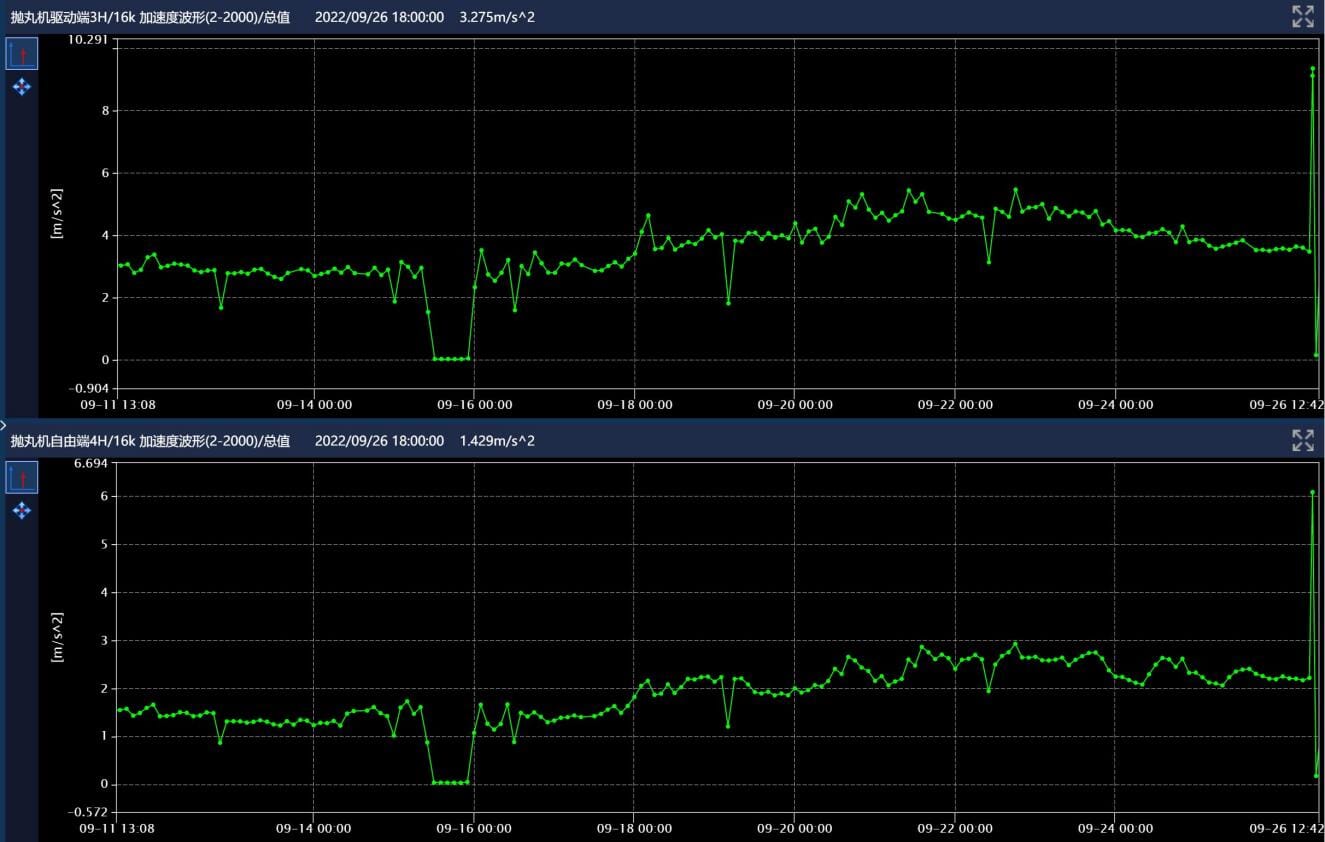

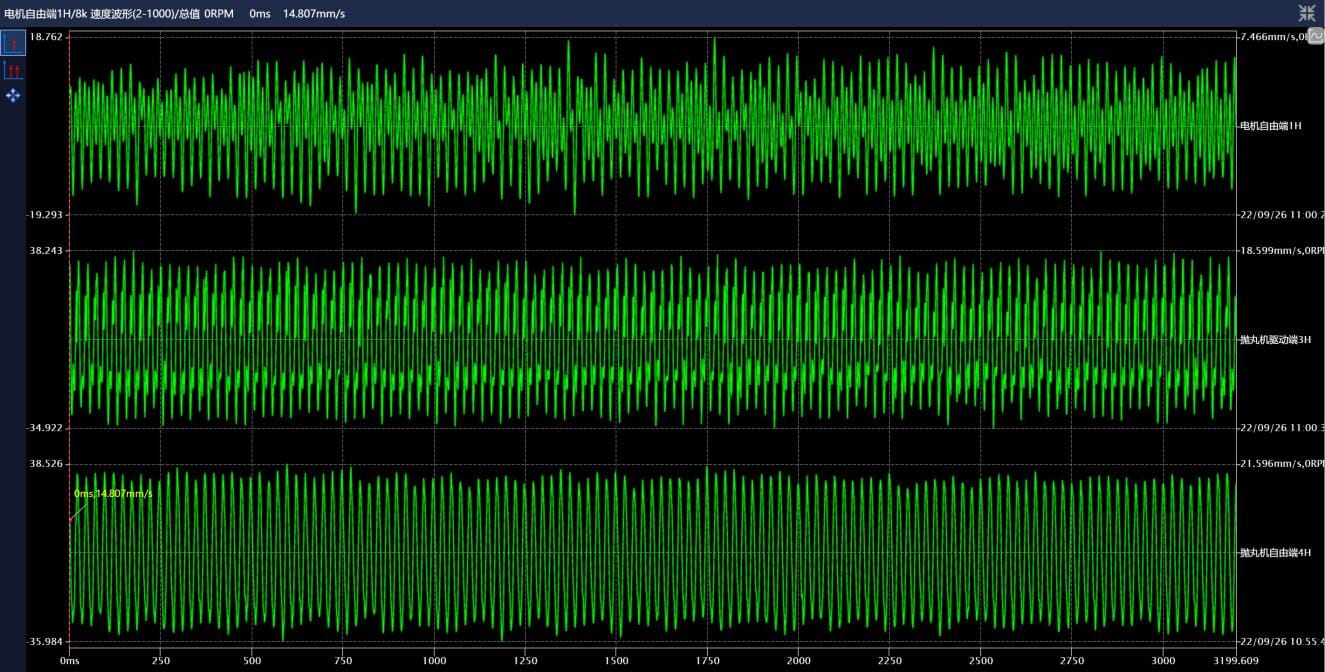

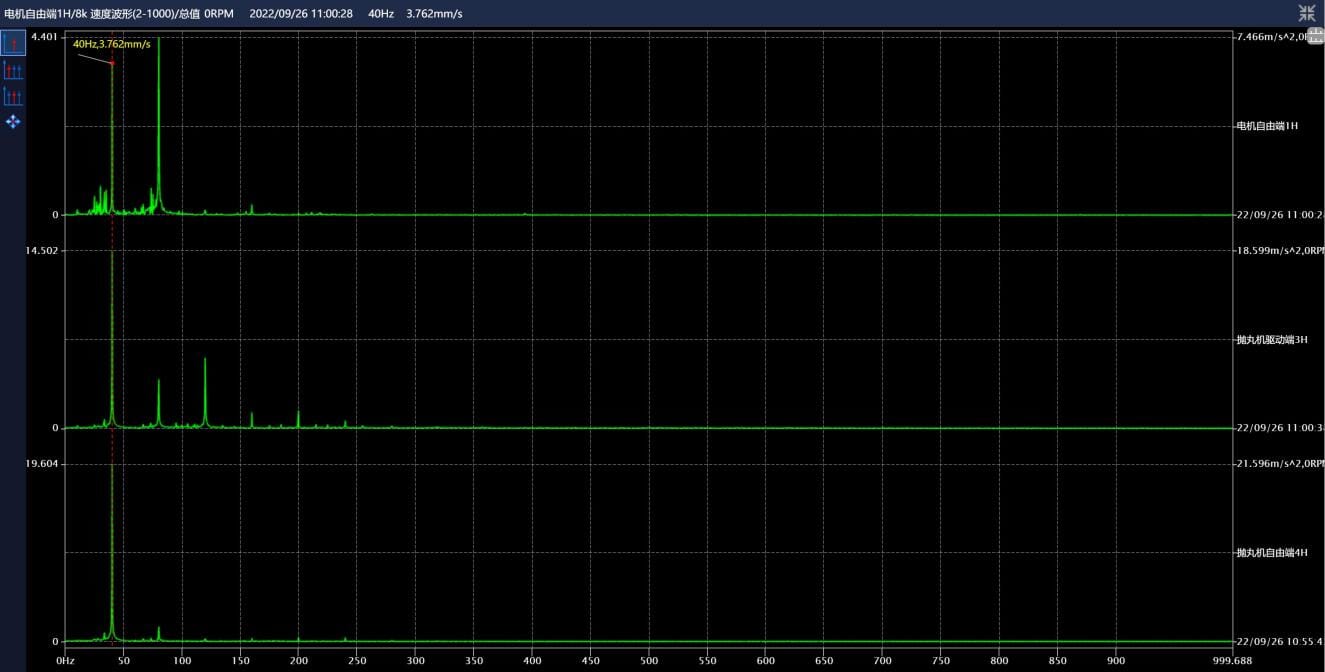

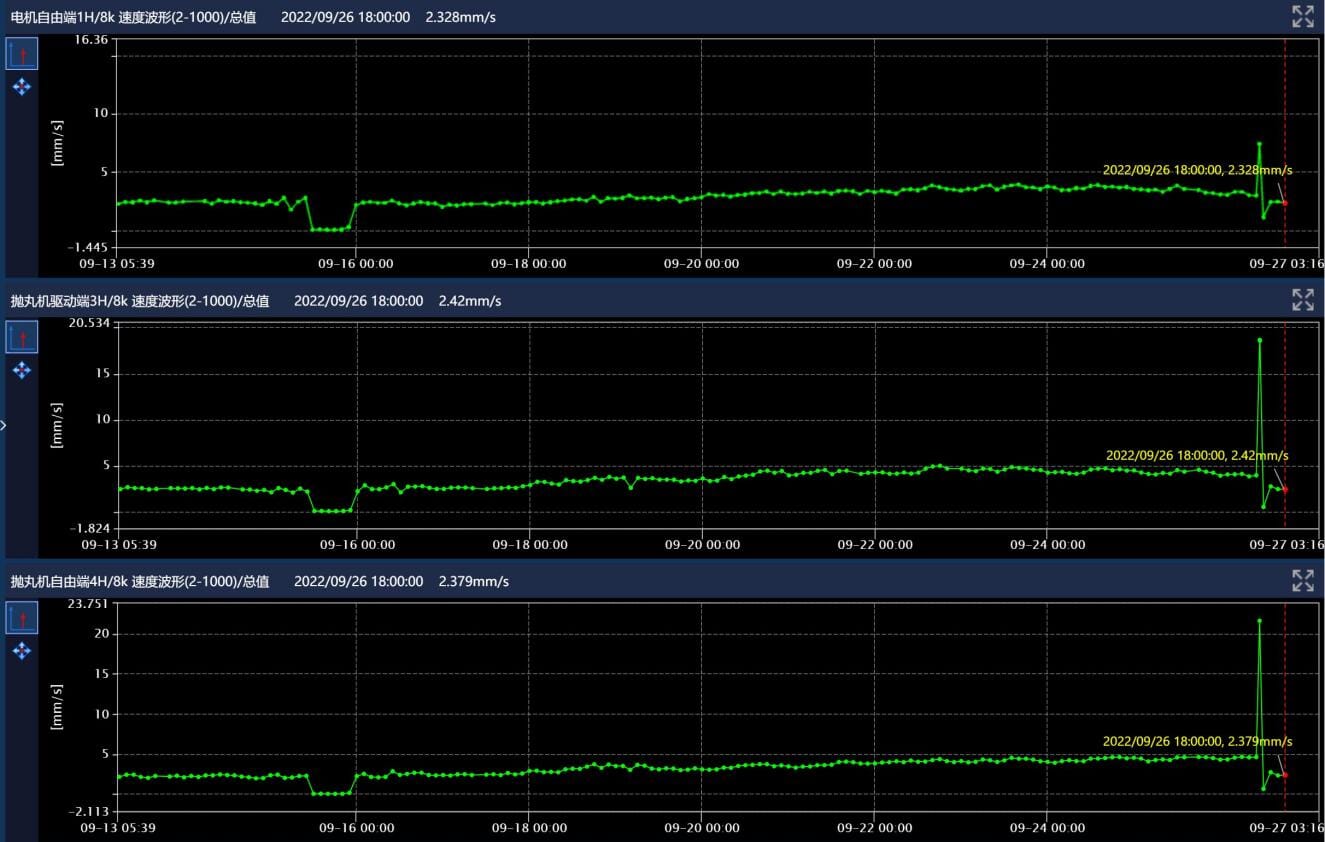

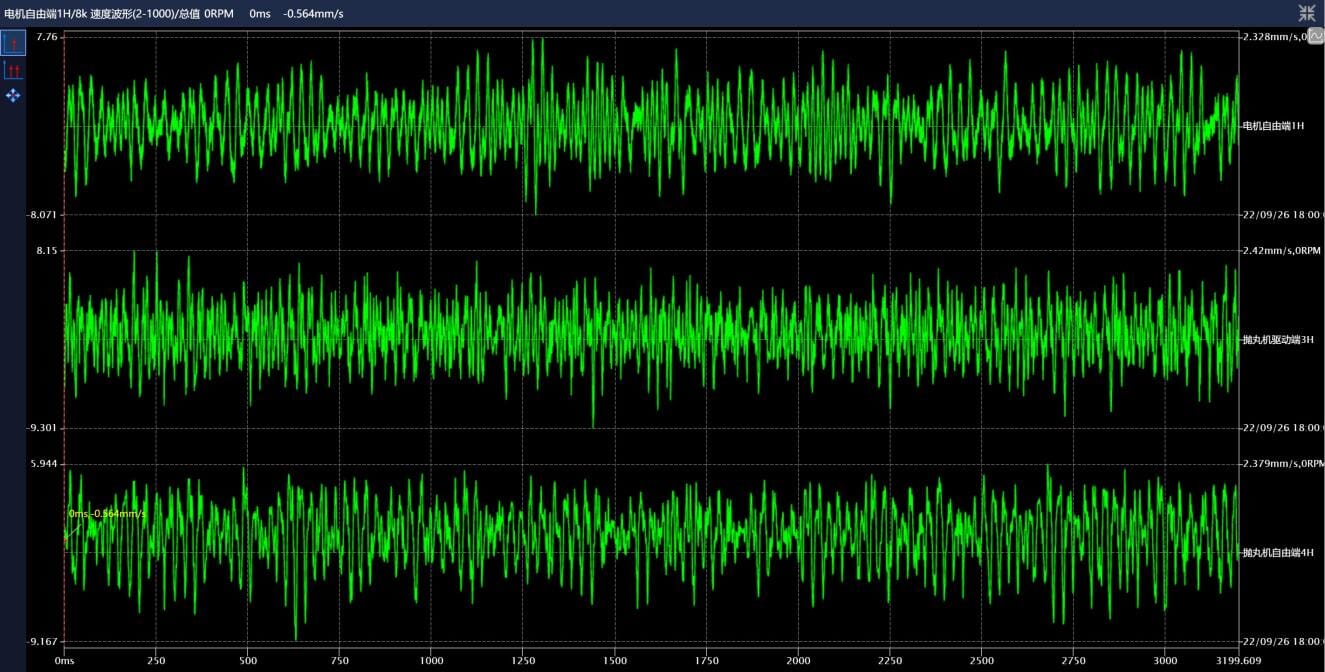

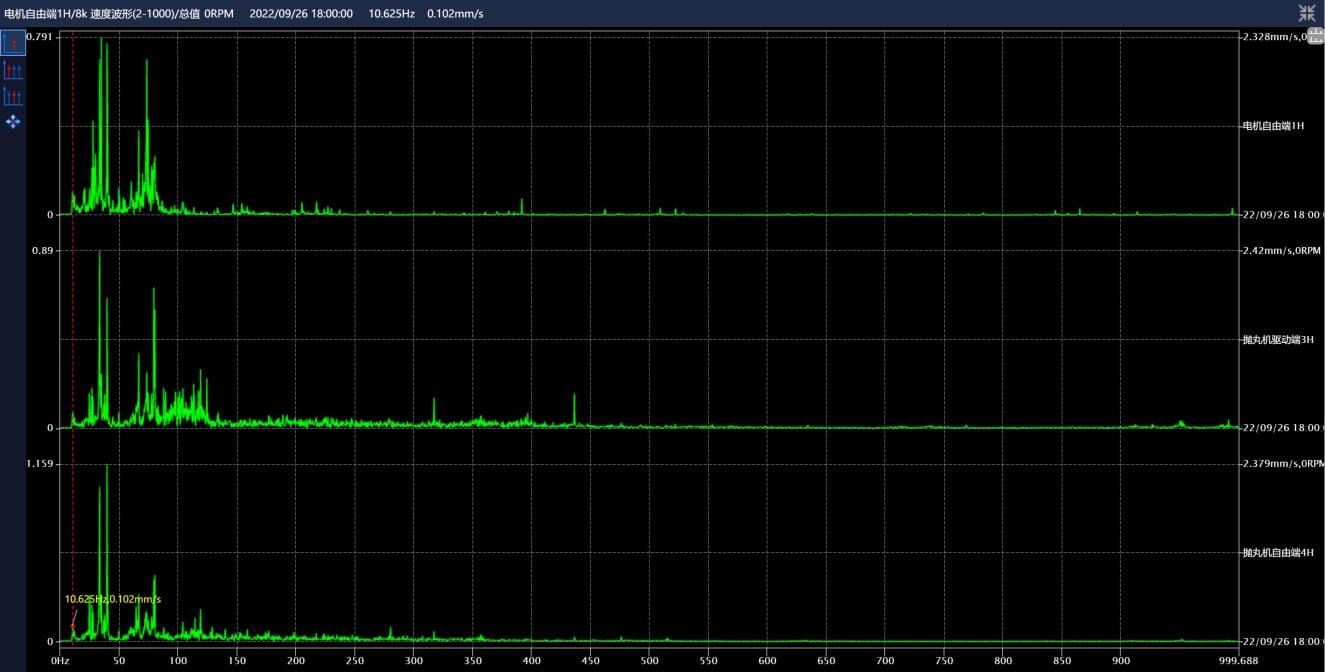

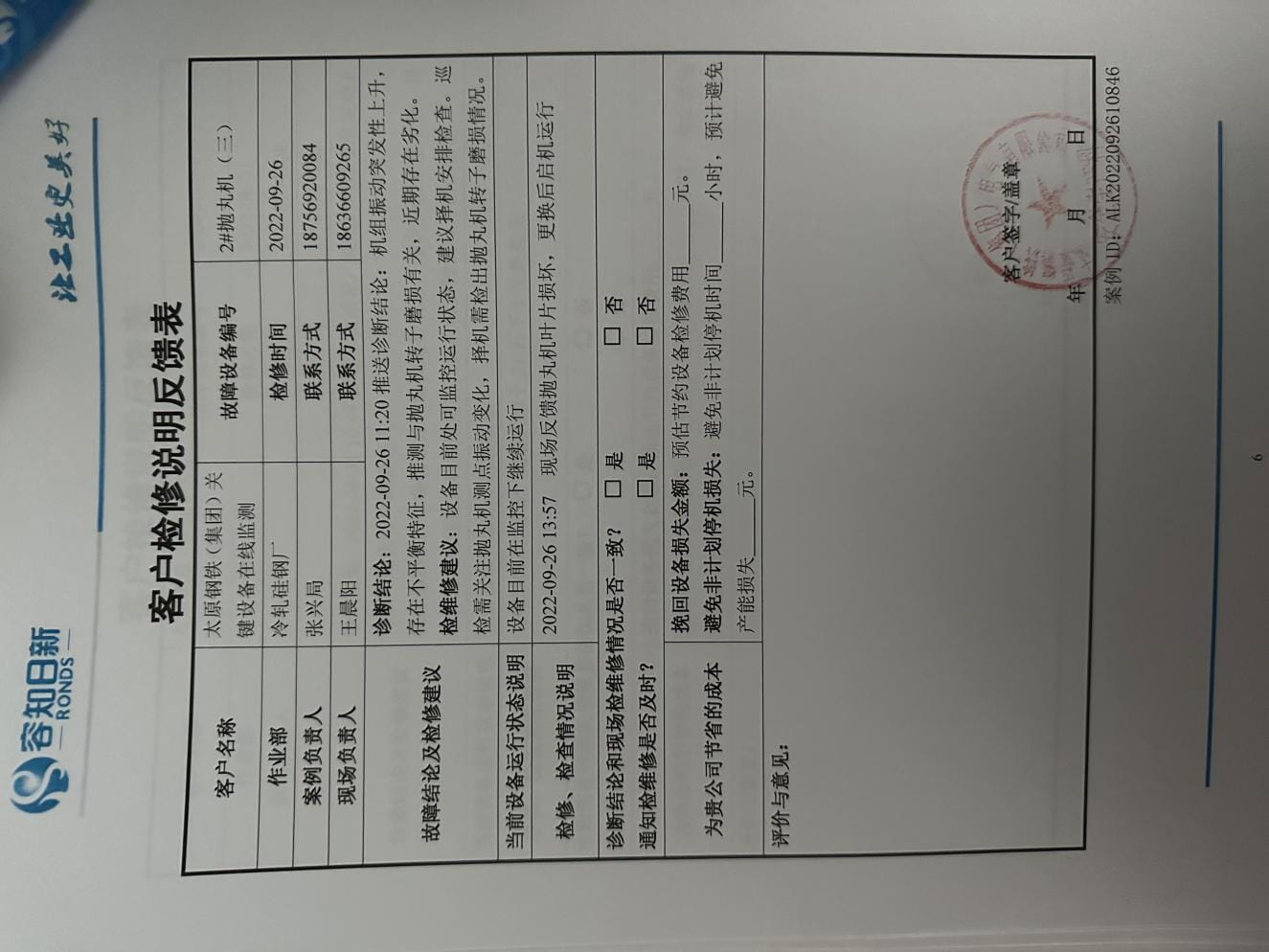

Taiyuan Iron & Steel Group Co., Ltd. #2 Shot Blasting Machine (3)

Taiyuan Iron & Steel Group Co., Ltd. #2 Shot Blasting Machine (3)Learn More

-

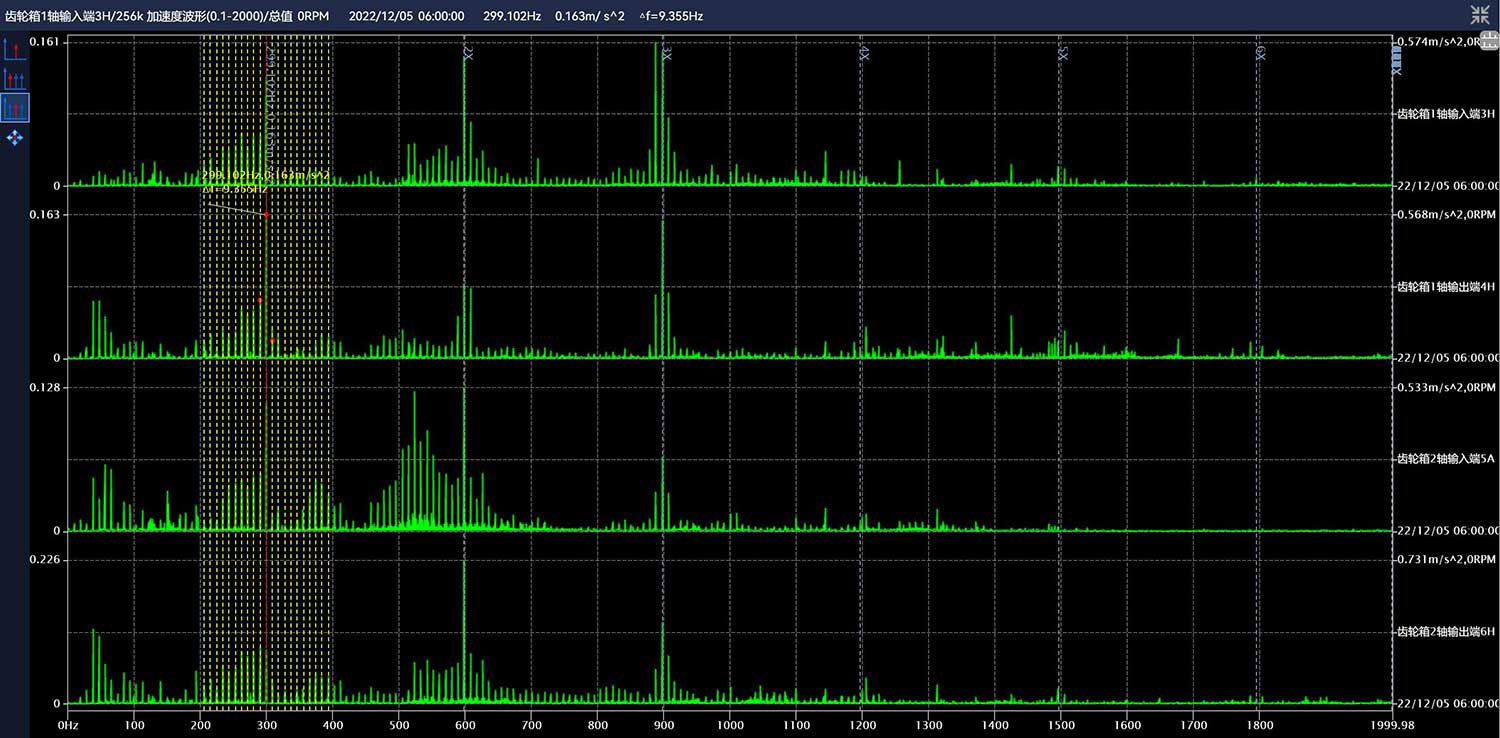

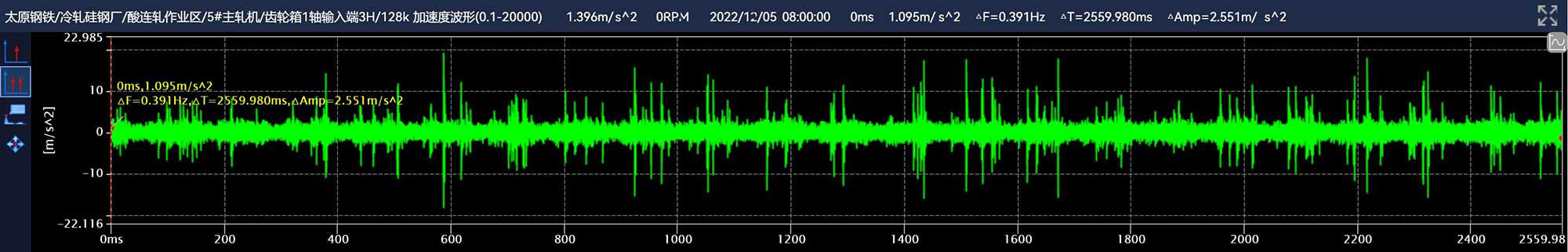

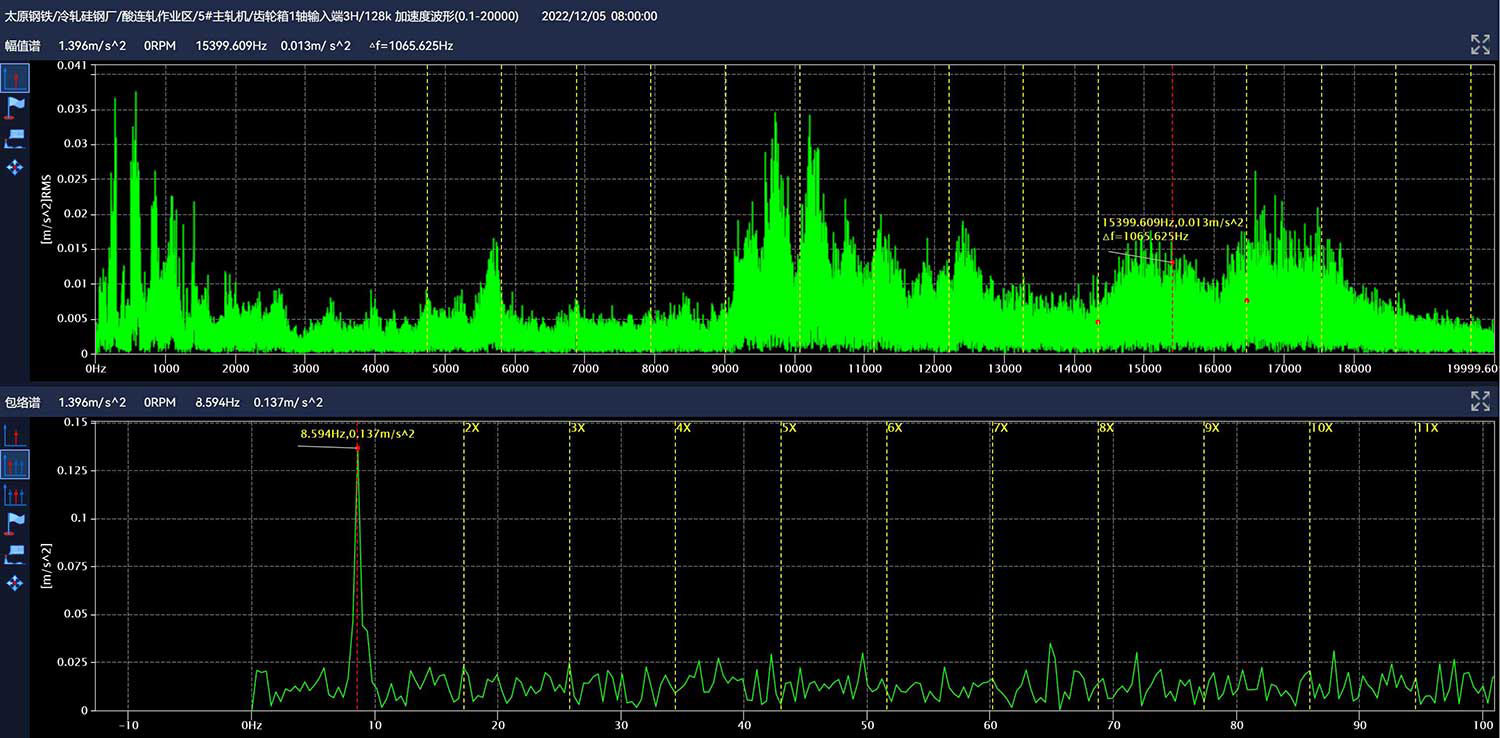

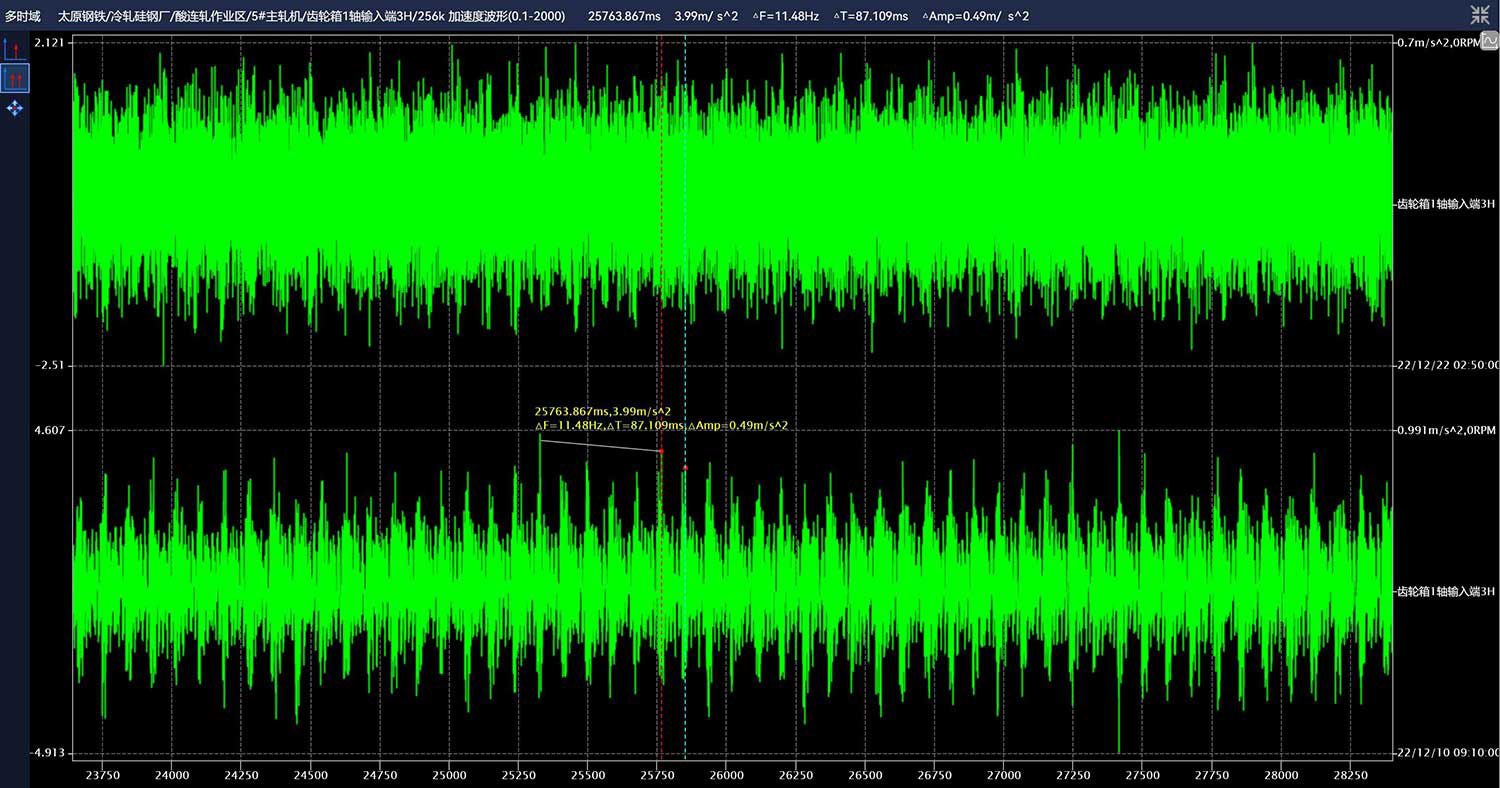

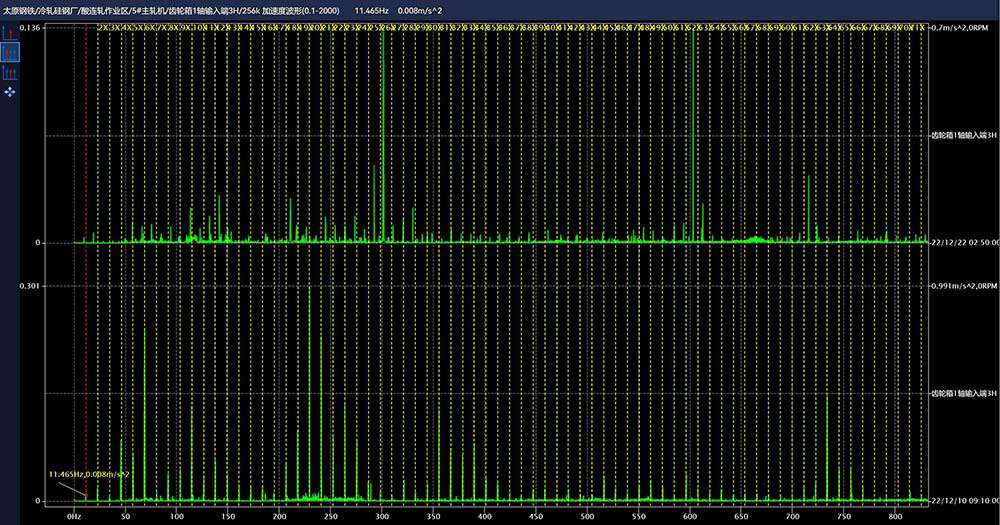

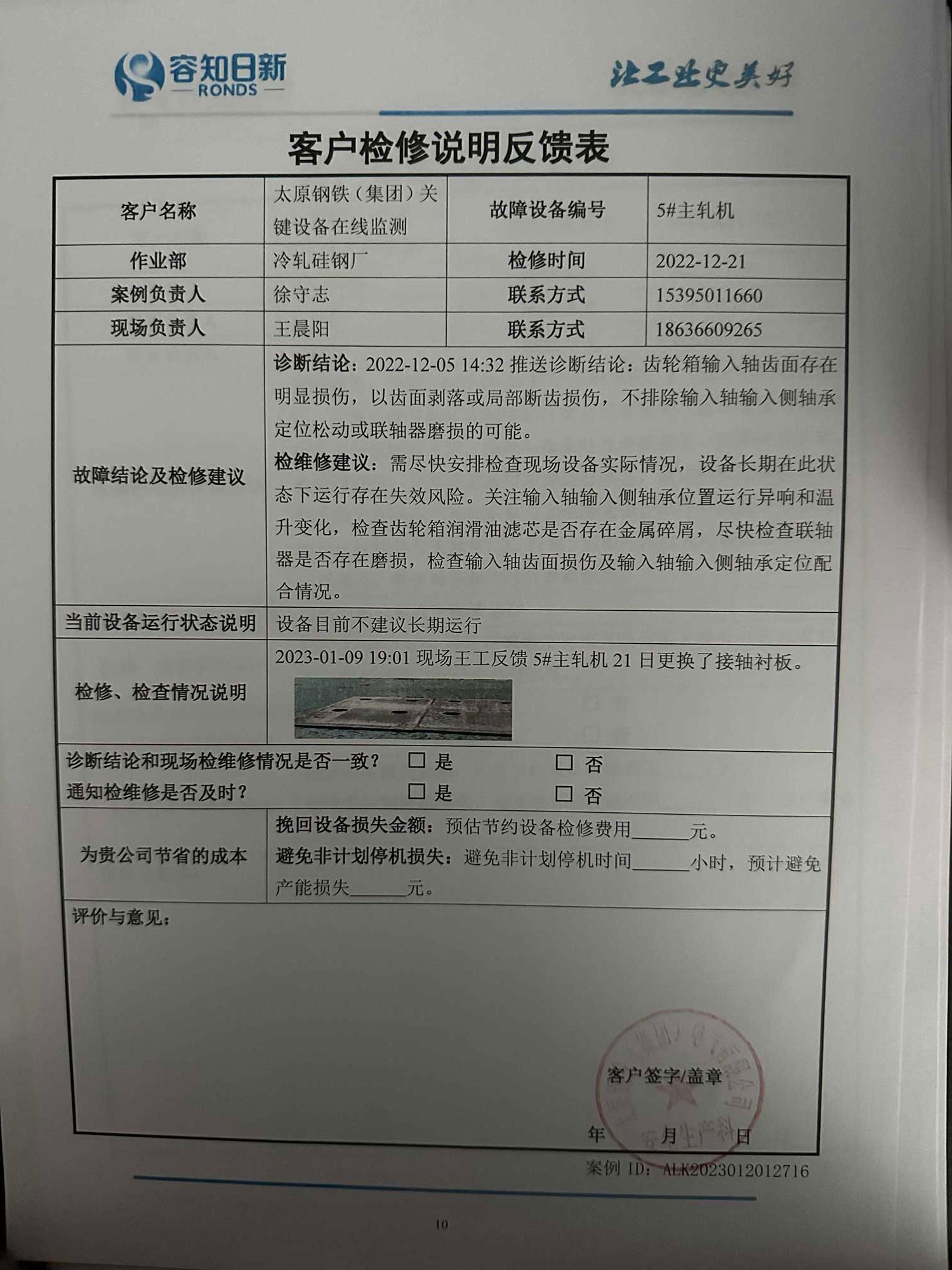

Taiyuan Iron & Steel Group Co., Ltd. Critical Equipment Online Monitoring #5 Main Rolling Mill

Taiyuan Iron & Steel Group Co., Ltd. Critical Equipment Online Monitoring #5 Main Rolling MillLearn More

-

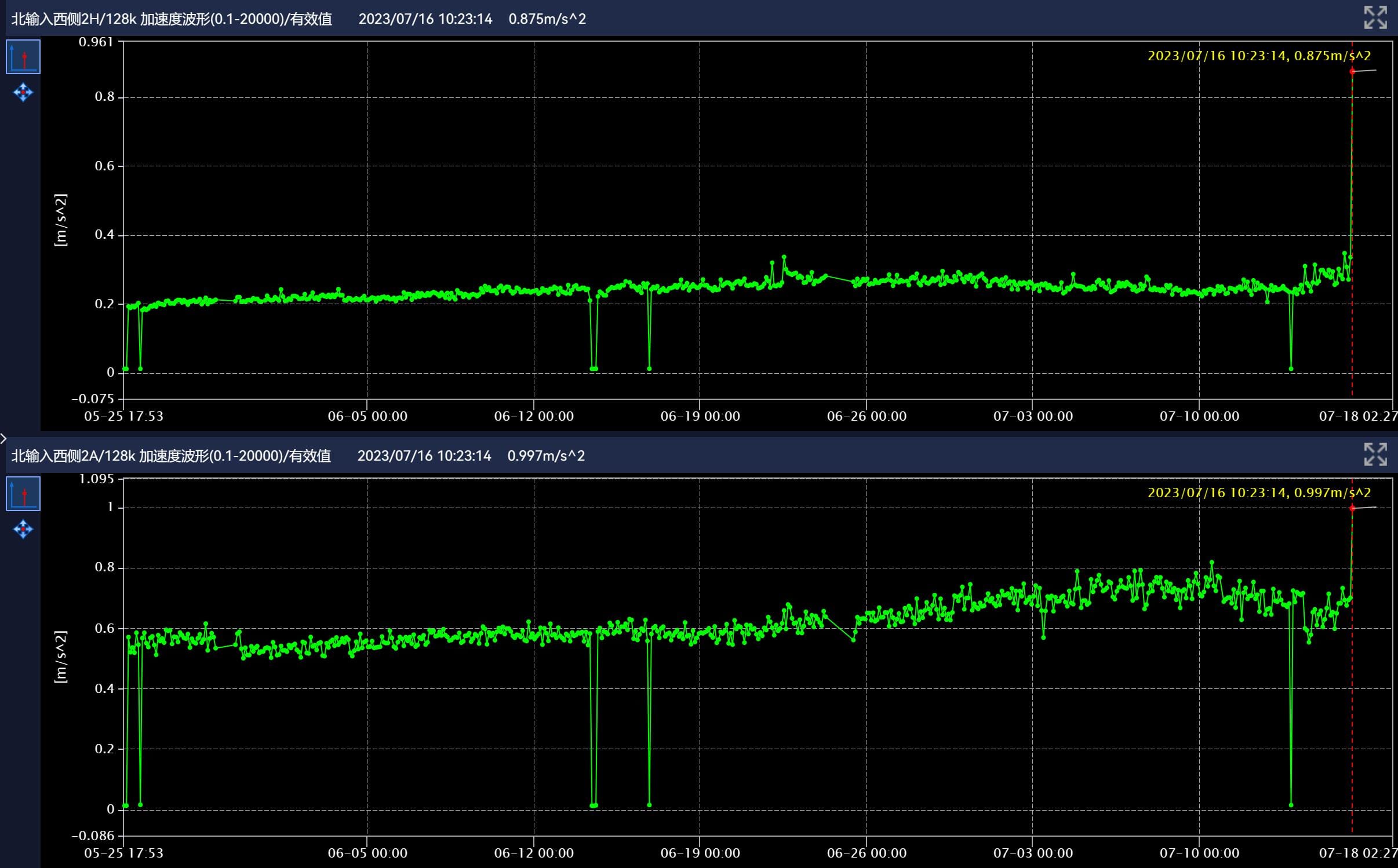

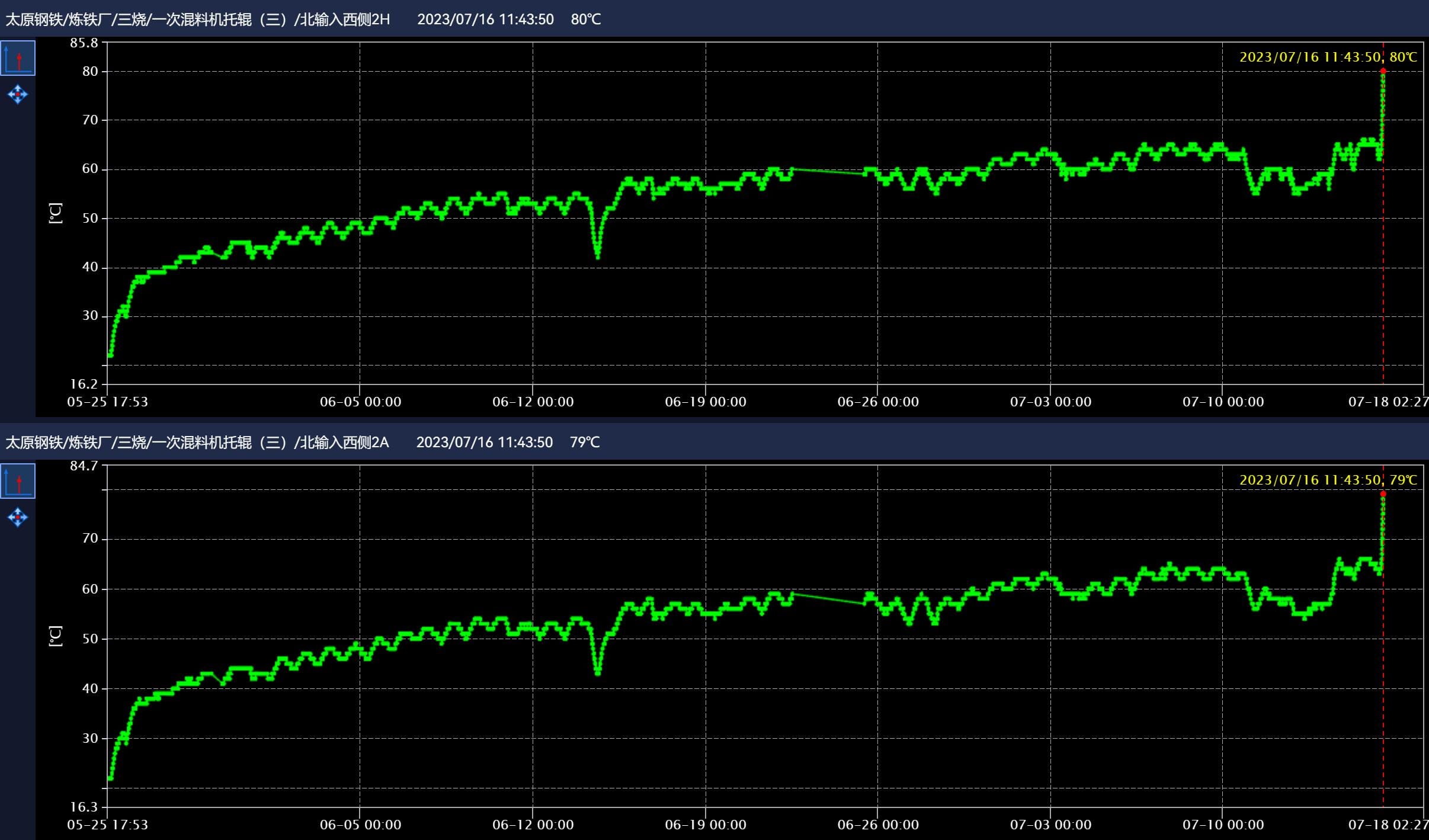

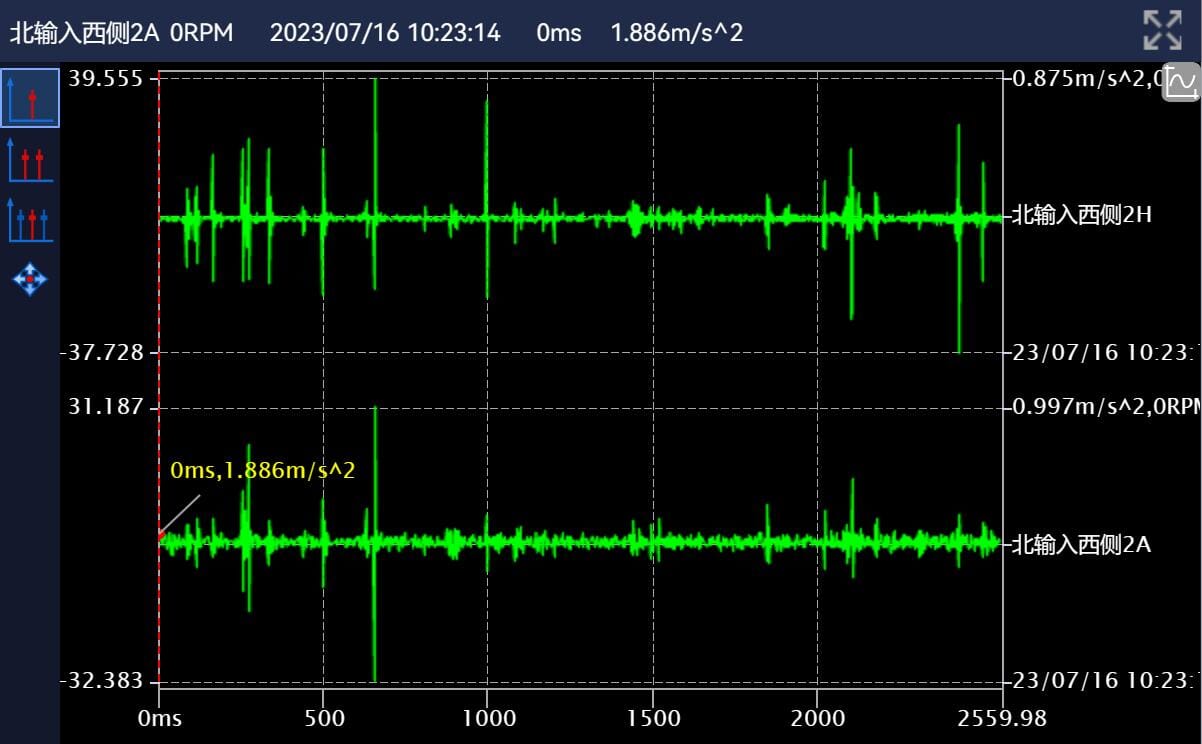

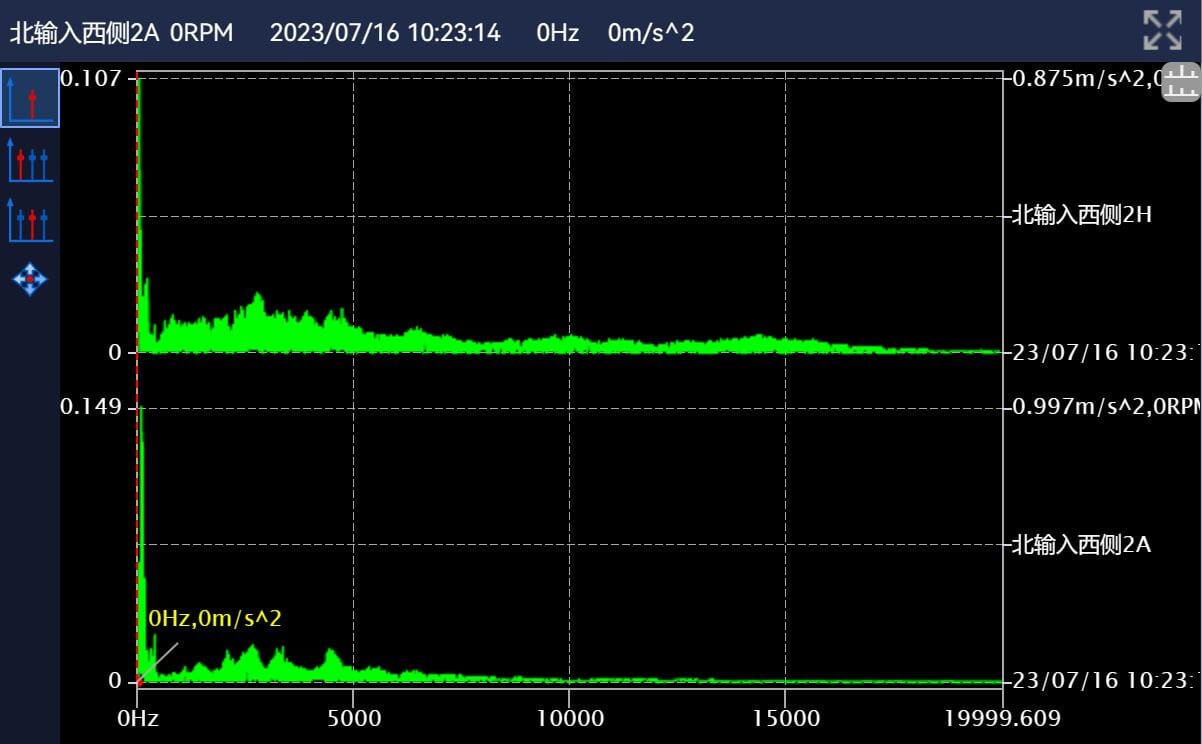

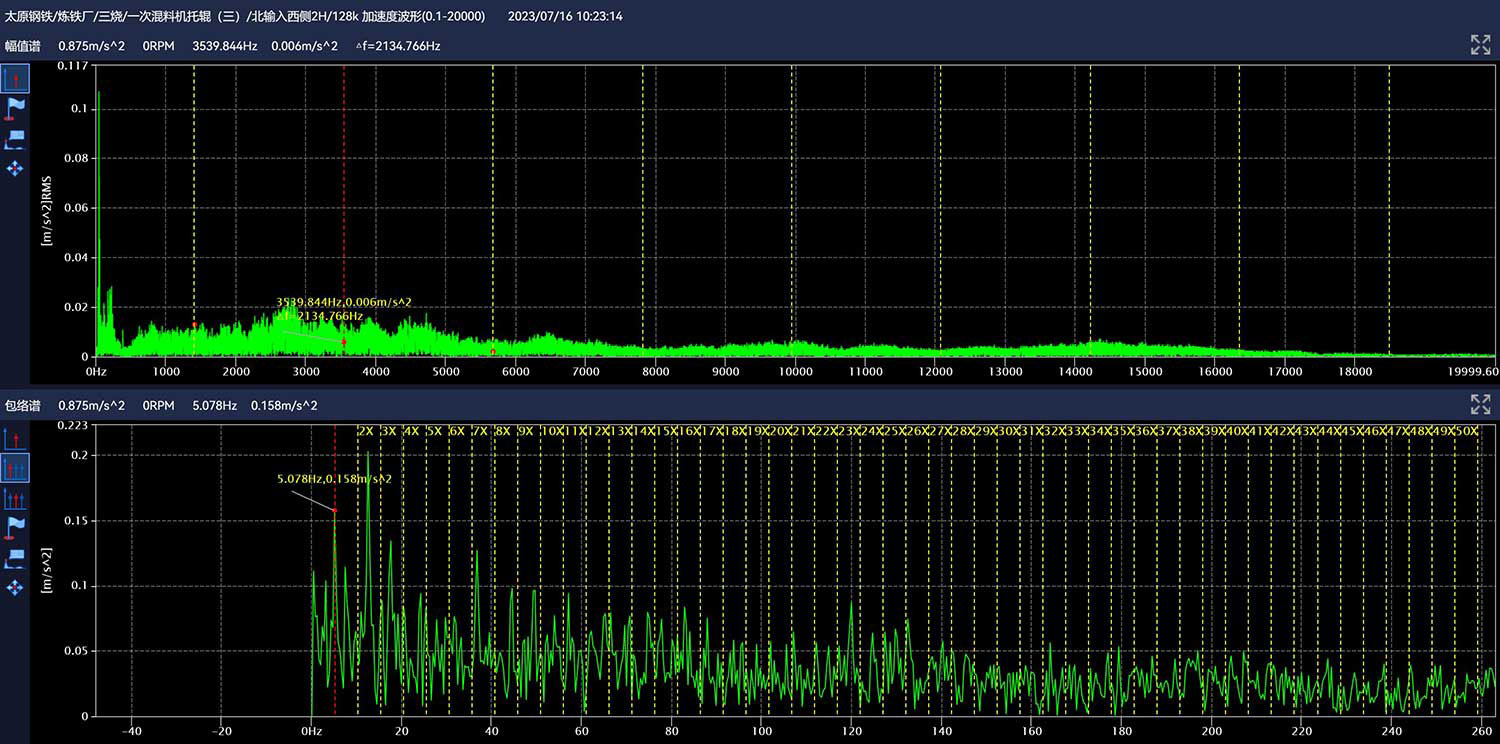

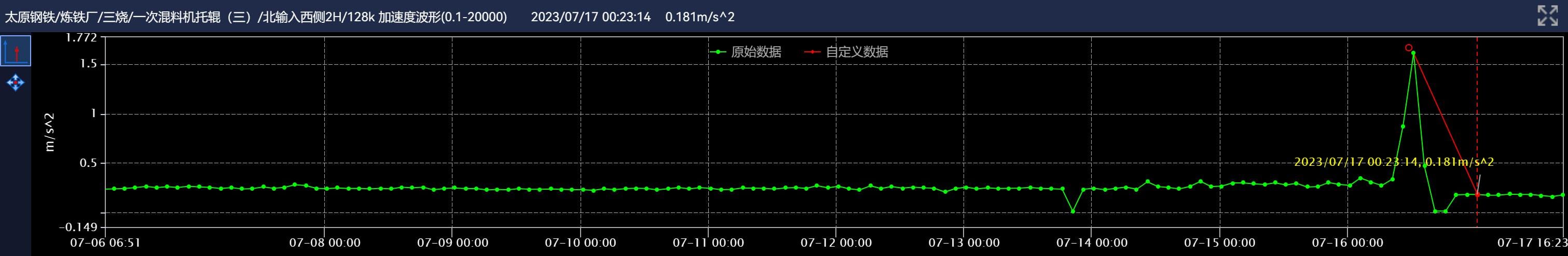

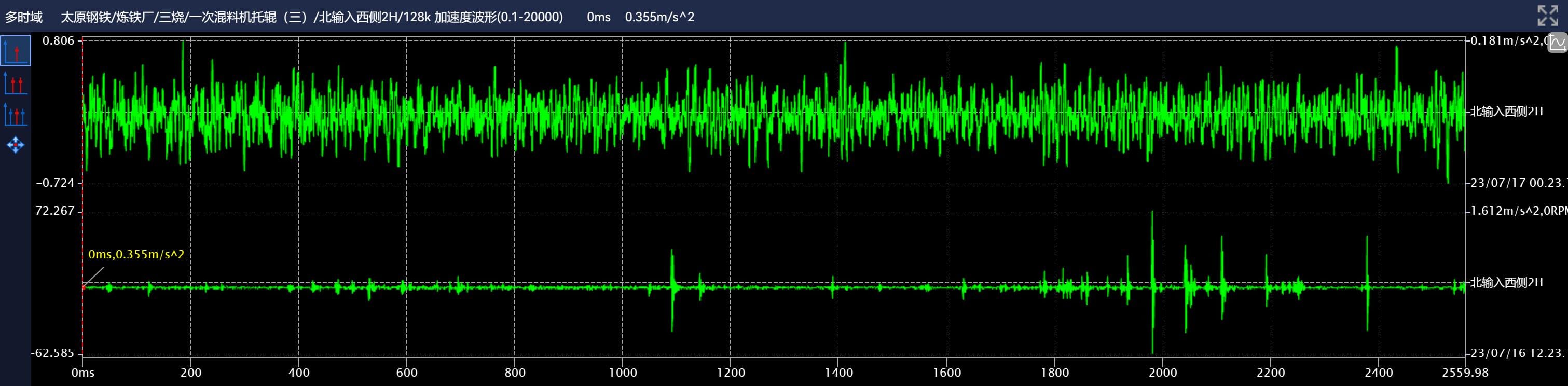

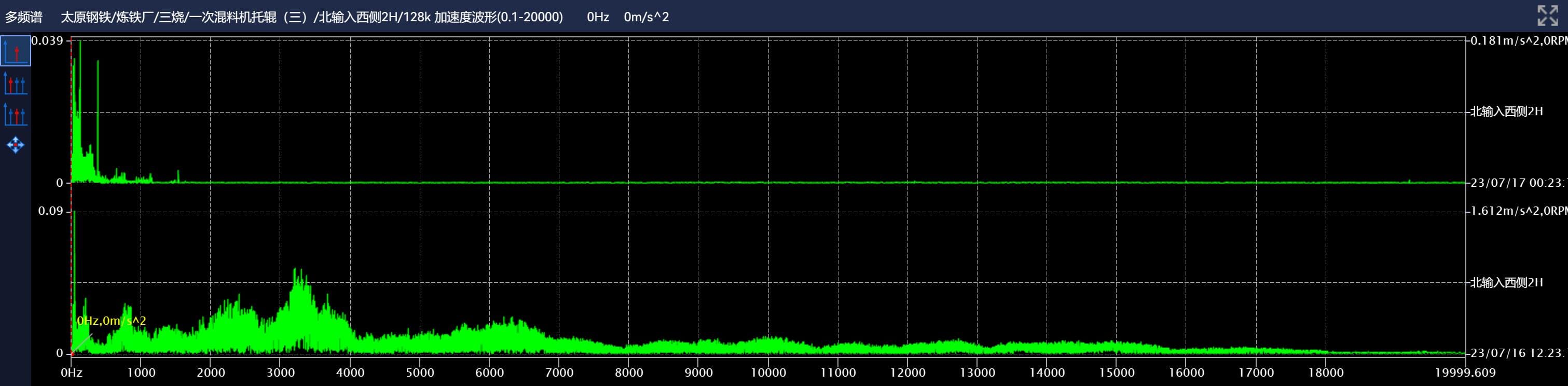

Taiyuan Iron & Steel Group Co., Ltd. Critical Equipment Online Monitoring Primary Mixer Support Roller (3)

Taiyuan Iron & Steel Group Co., Ltd. Critical Equipment Online Monitoring Primary Mixer Support Roller (3)Learn More

Start Your Journey to Intelligent Industrial Equipment Maintenance