Condition Monitoring for 100+ Wind Farms, Precision Alerts Ensure Stable Operation of Aging Assets

Case Time:

2012 - Present (12+ Years)

Client Background:

China Huadian Corporation Ltd. is one of China's five state-owned power generation giants established during the power sector reform. As an extra-large central enterprise supervised by SASAC, it is authorized by the State Council as a pilot institution for state-invested and state-controlled companies.

Client Requirements & Solutions

Retrofitting for Data Integration, Comprehensive Turbine Health Management

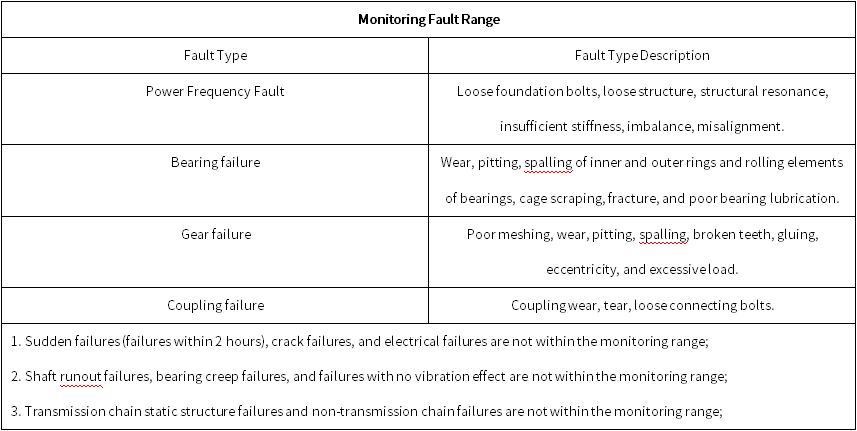

Real-time Monitoring of Critical Components & Enhanced Auxiliary System Data Utilization:

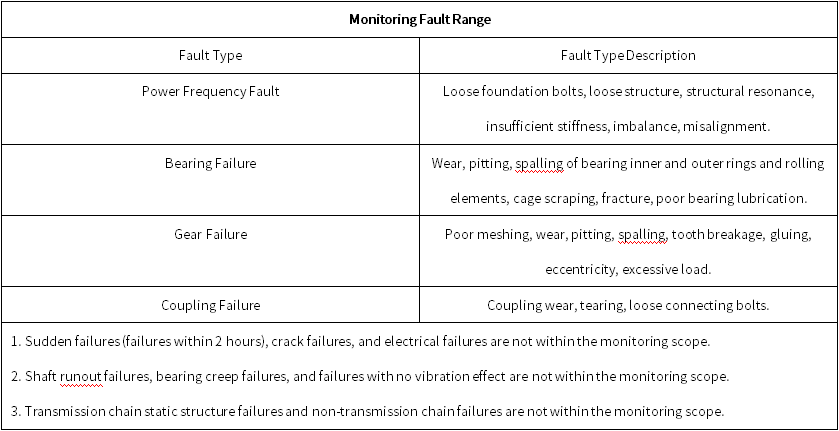

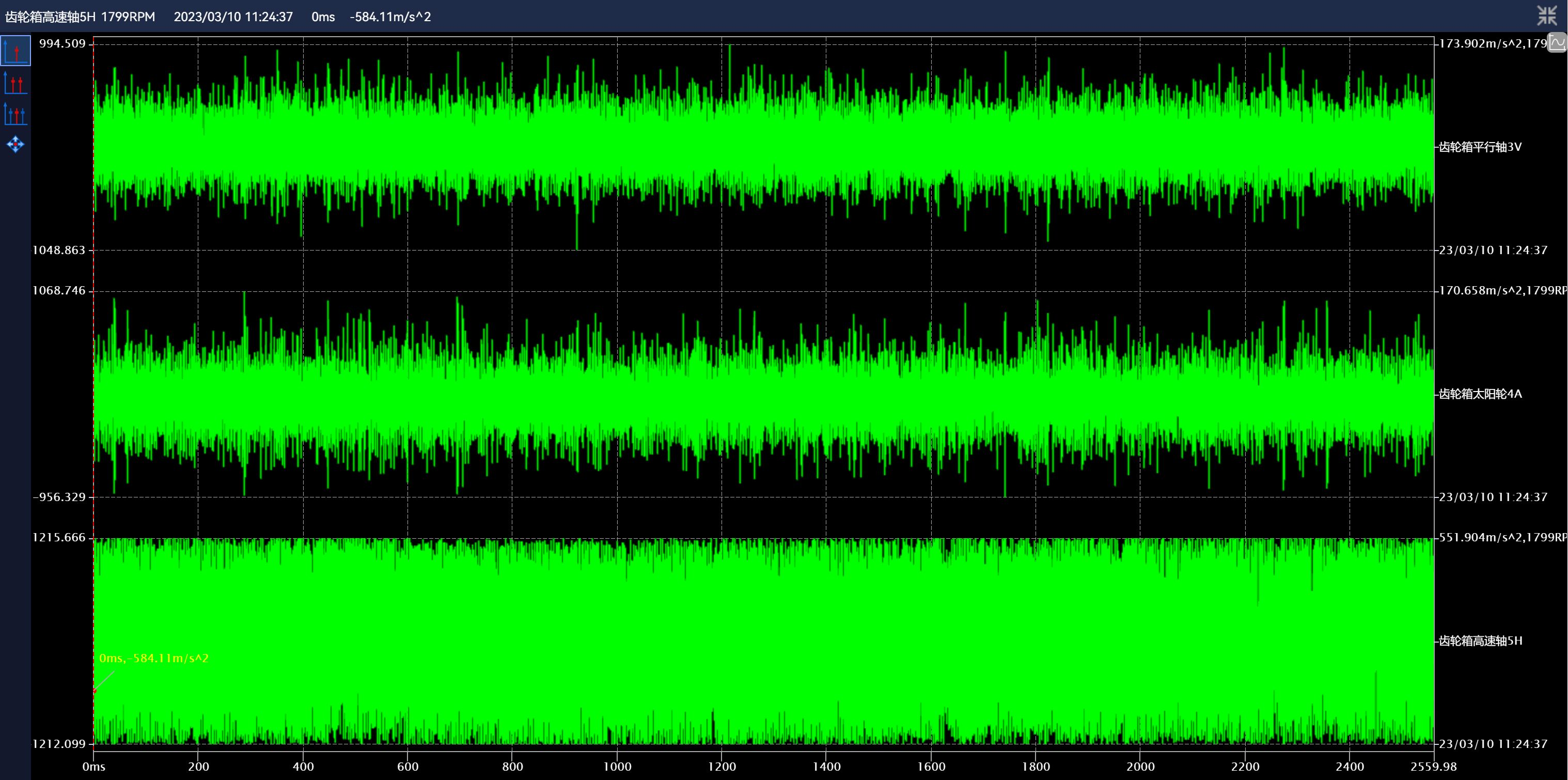

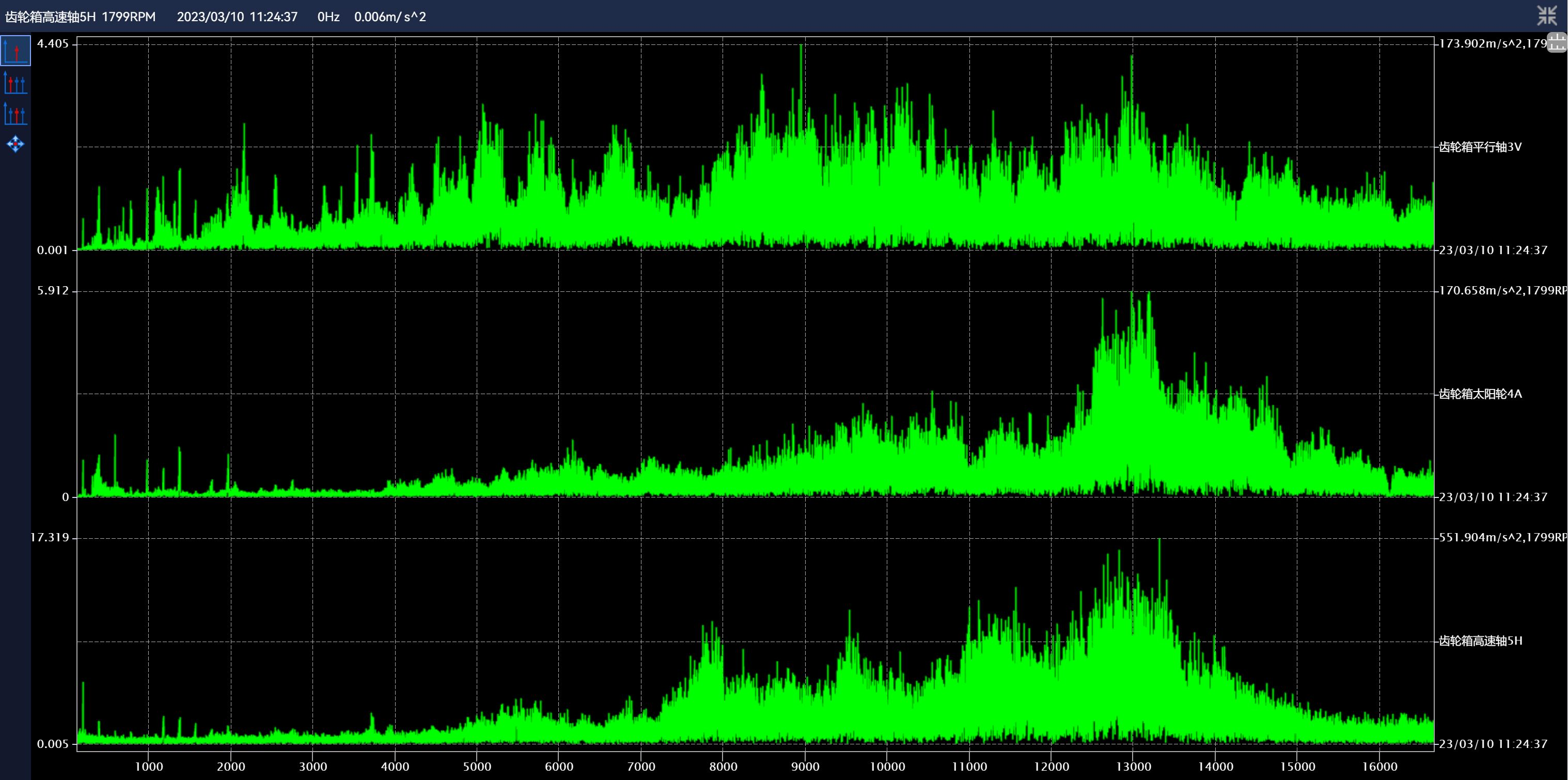

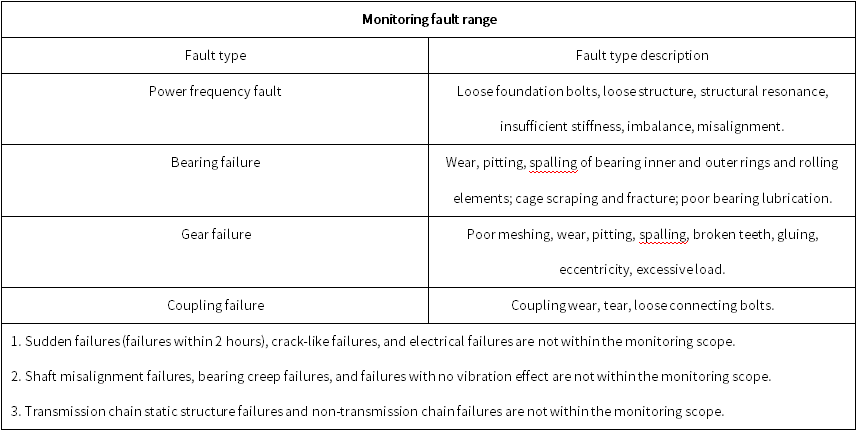

The client sought to deploy CMS systems for 1.5MW/2.0MW turbines operating over 5 years, enabling real-time monitoring of major components and comprehensive operational visibility.

Ronds' Solution:

For legacy wind farms: Provided backward-compatible hardware replacements and lifetime software upgrade support for auxiliary systems aged 5+ years

Integrated "Wind Farm-Regional-Control Center" data channels in collaboration with Guodian Nanjing Automation Co., Ltd.

Predictive Maintenance for Key Components:

Customized monitoring solutions for blades, towers, bolts, etc., with condition assessment and predictive analytics applied to high-capacity multi-MW turbines like:

Large-scale projects (Hinggan League)、Offshore installations (Yuhuan City in Taizhou)

Application Value

Wind Farms Monitored: 150+

Turbines Covered: 5400+

Health Reports Generated: 4000+

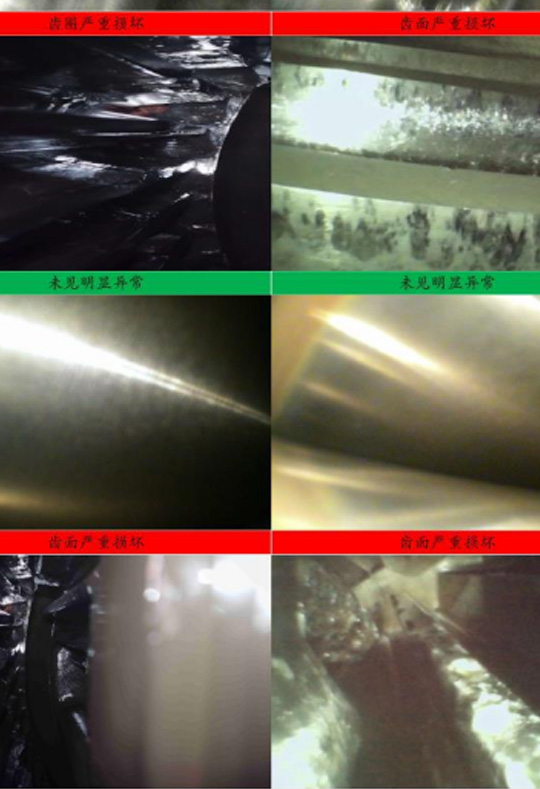

Closed-Loop Cases Resolved: 800+

Multi-Region Retrofits Unify Group-Wide Data Flow:

Upgraded systems across Xinjiang, Ningxia, Shaanxi, Gansu, and Yunnan, replacing defunct CMS hardware at reduced costs while establishing integrated data links with Huadian Electric Power Research Institute CO., Ltd..

Enabling Smart Wind Farm Development:

Through component-level data aggregation and predictive analysis, Ronds supports Huadian's intelligent wind farm initiative, pioneering centralized monitoring and diagnostic management models for renewable assets.

Success Cases

-

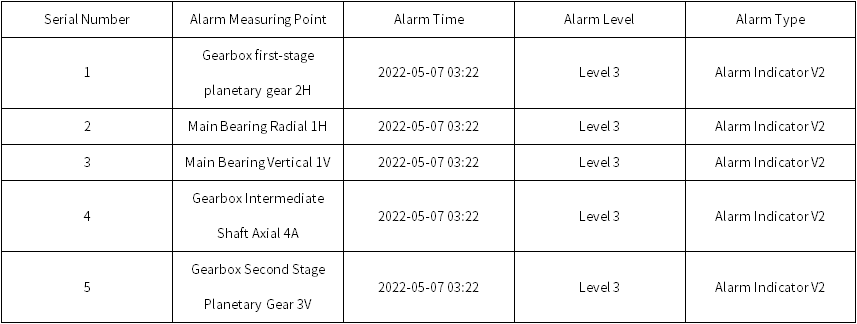

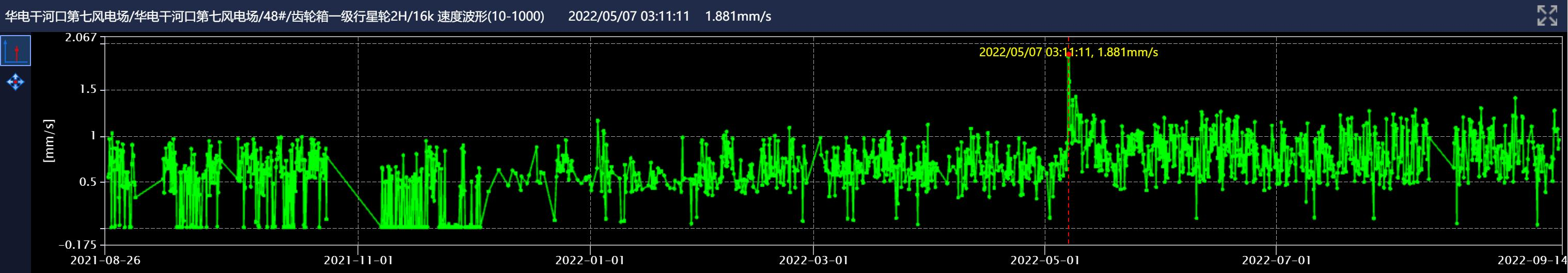

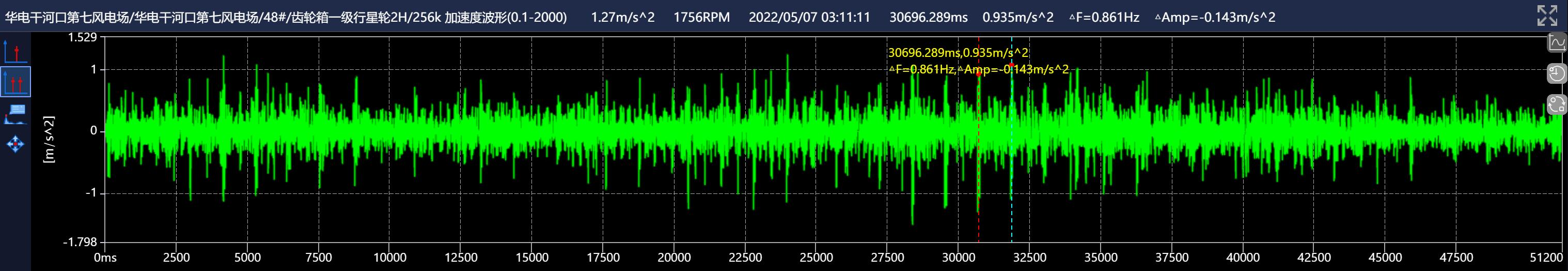

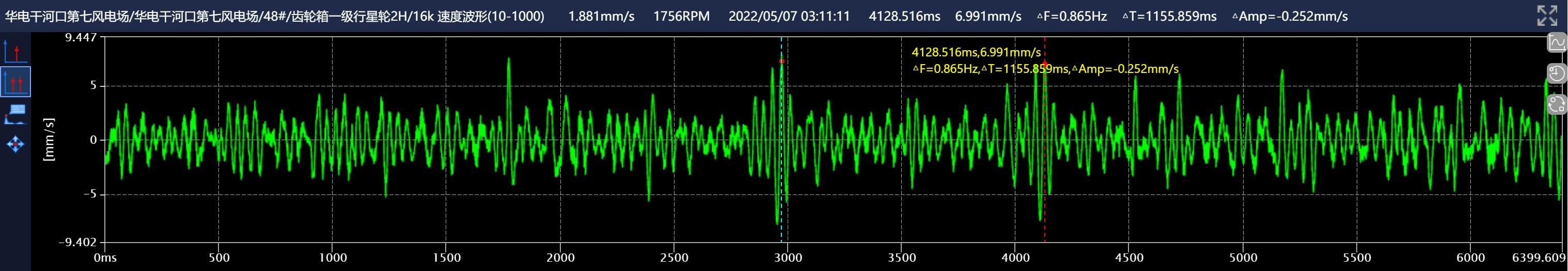

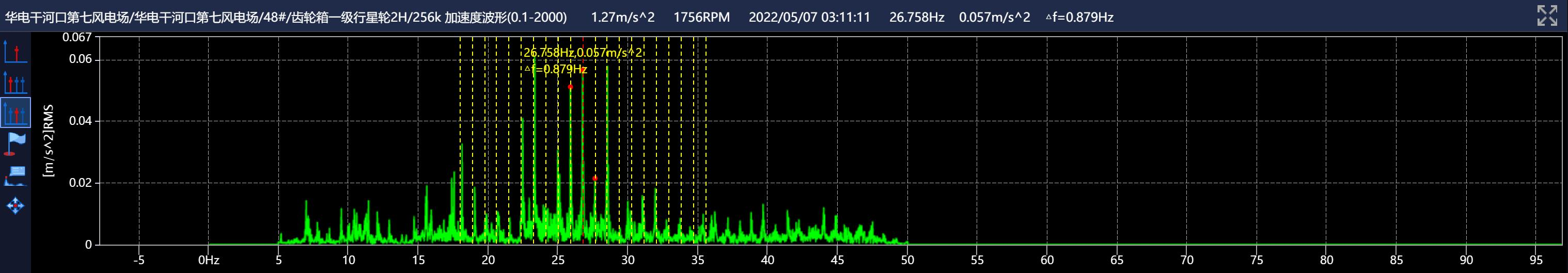

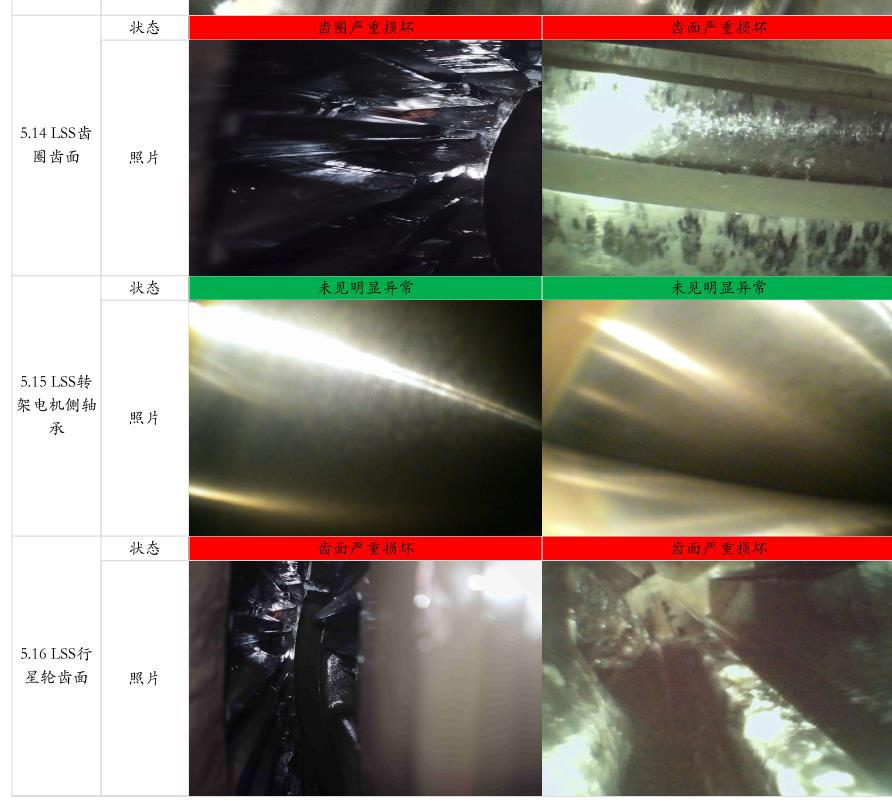

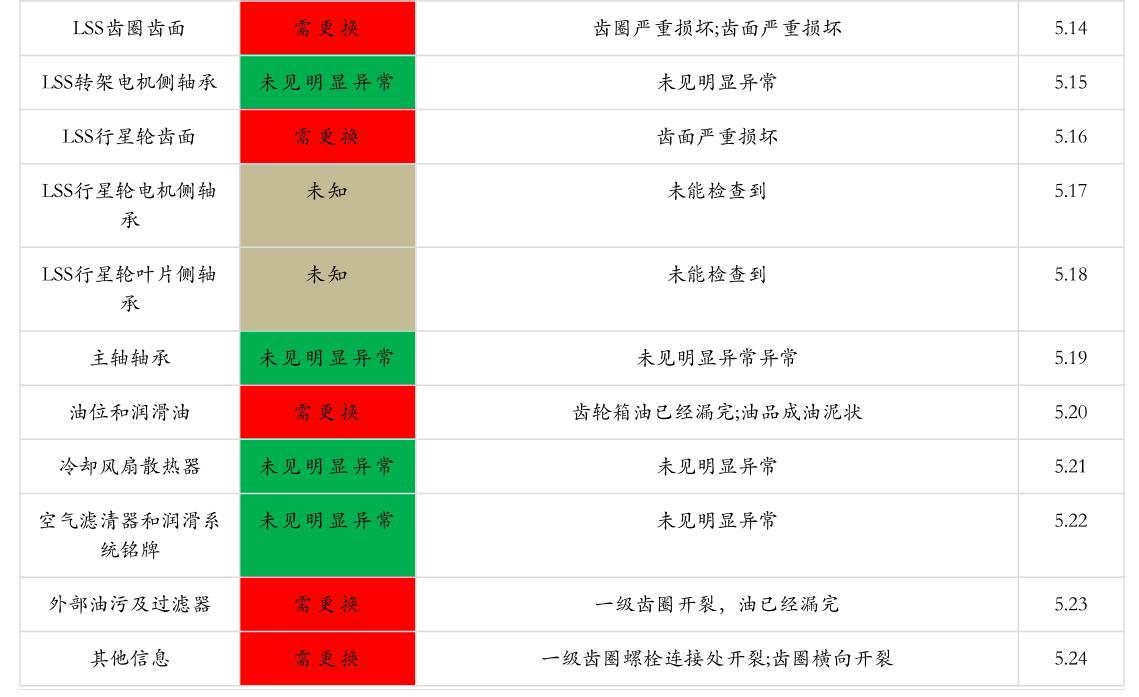

Gansu Huadian Guazhou Wind Power Co., Ltd. 48#

Gansu Huadian Guazhou Wind Power Co., Ltd. 48#Learn More

-

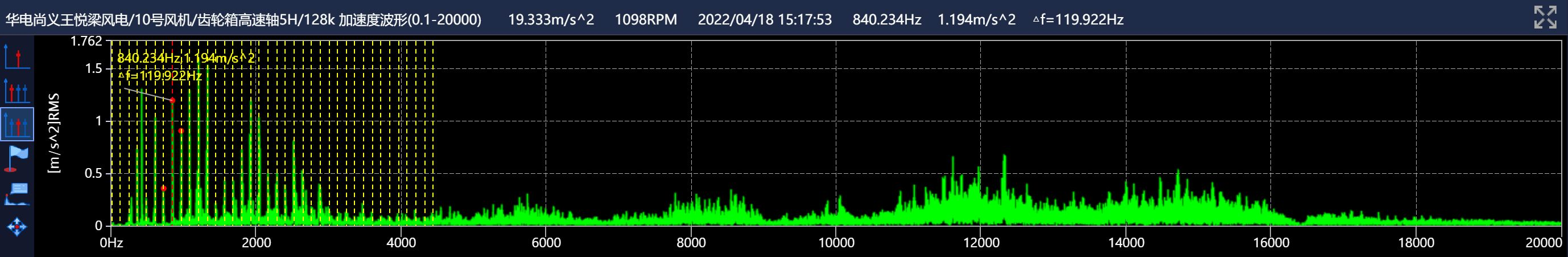

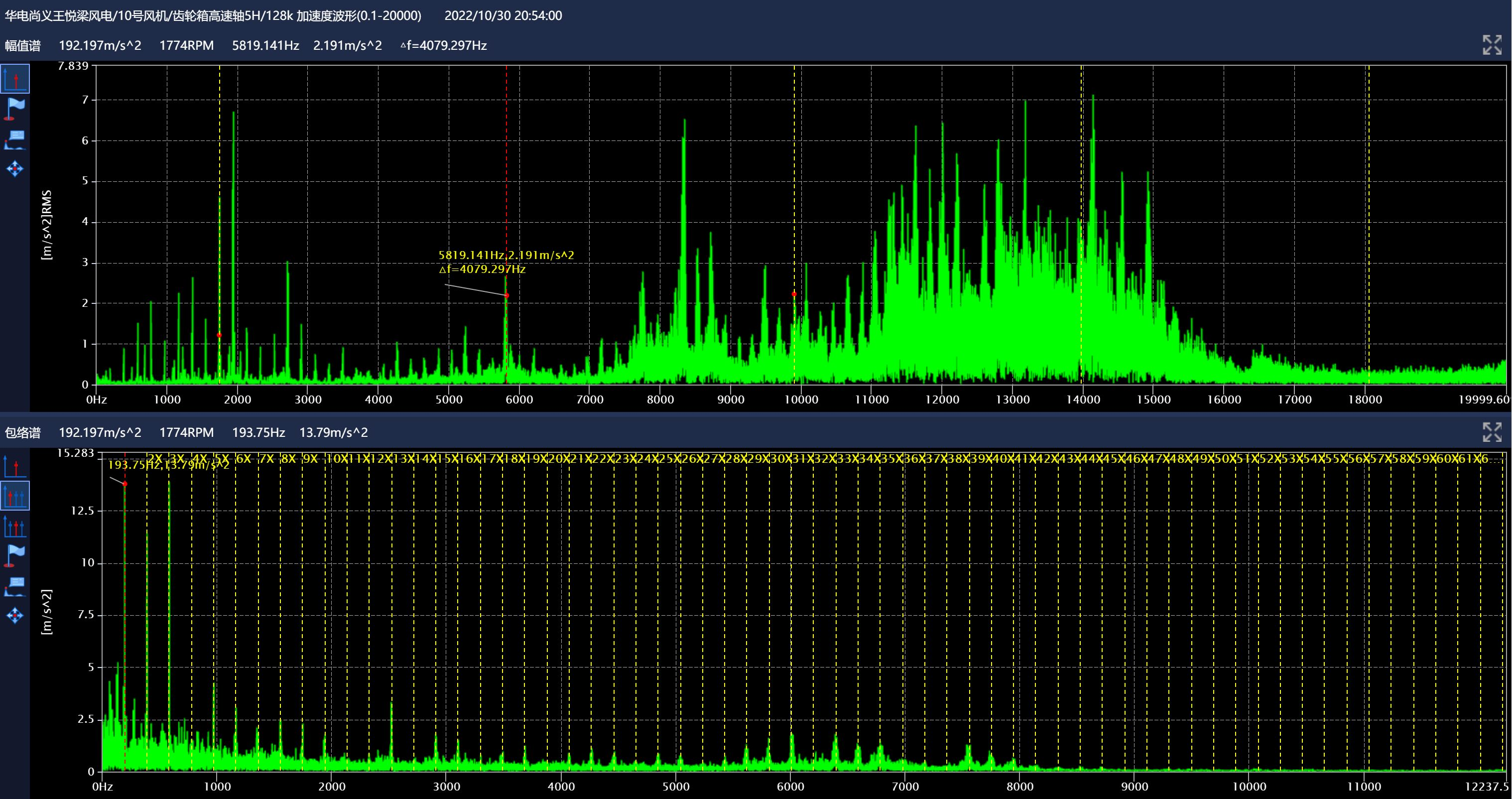

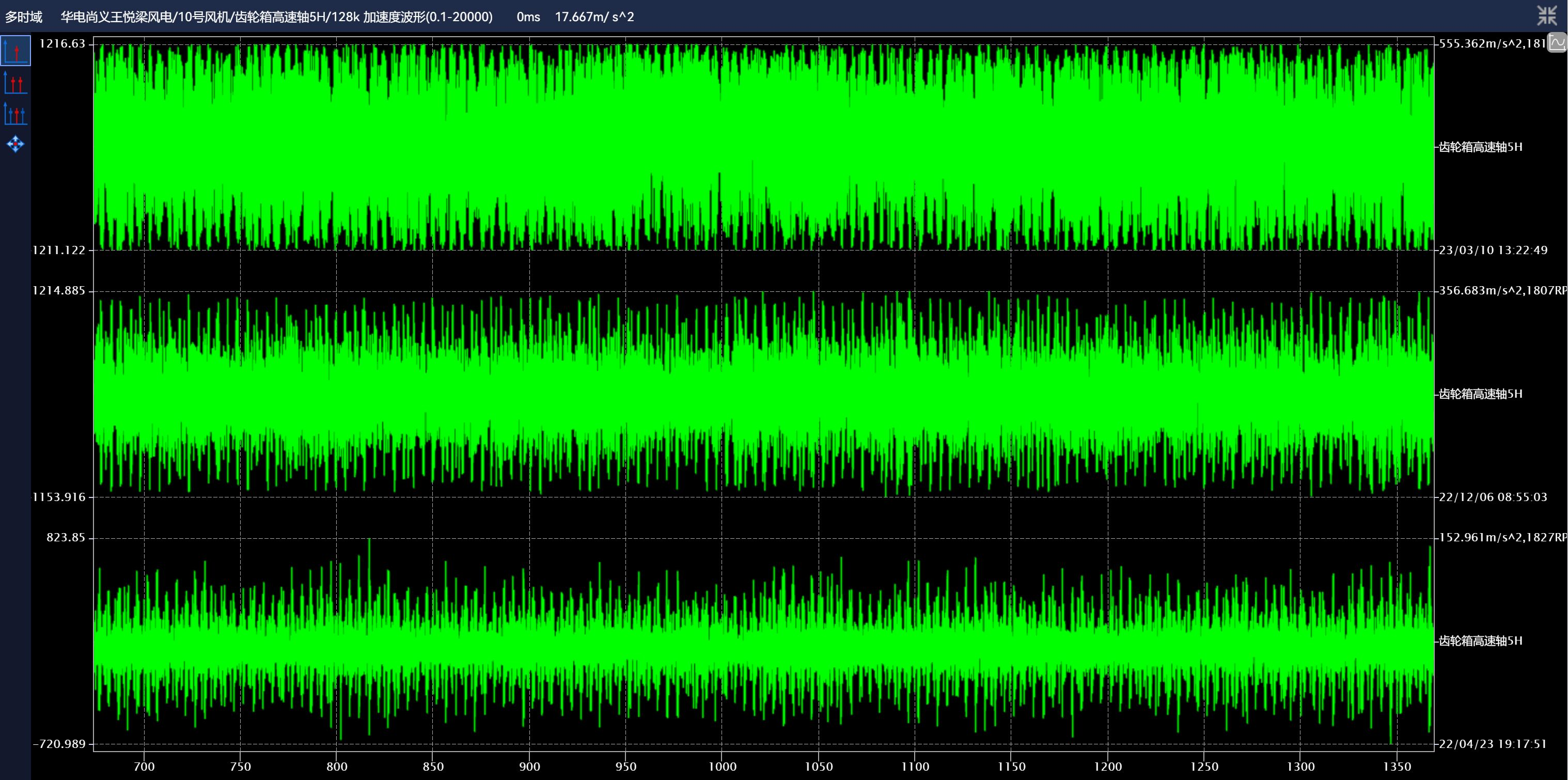

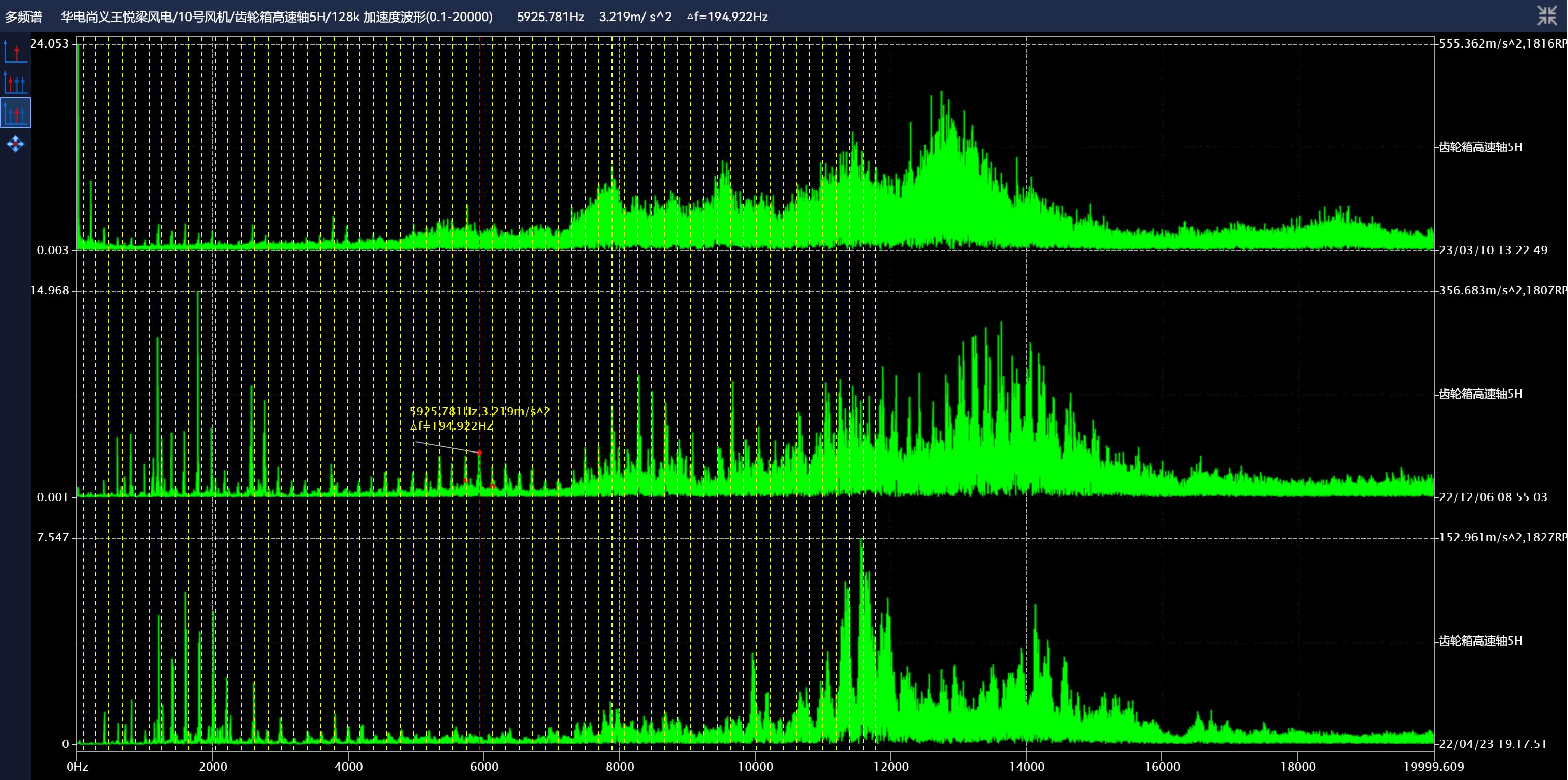

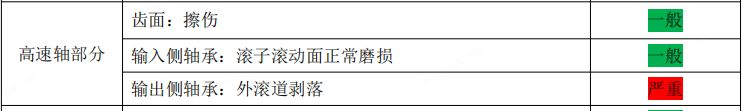

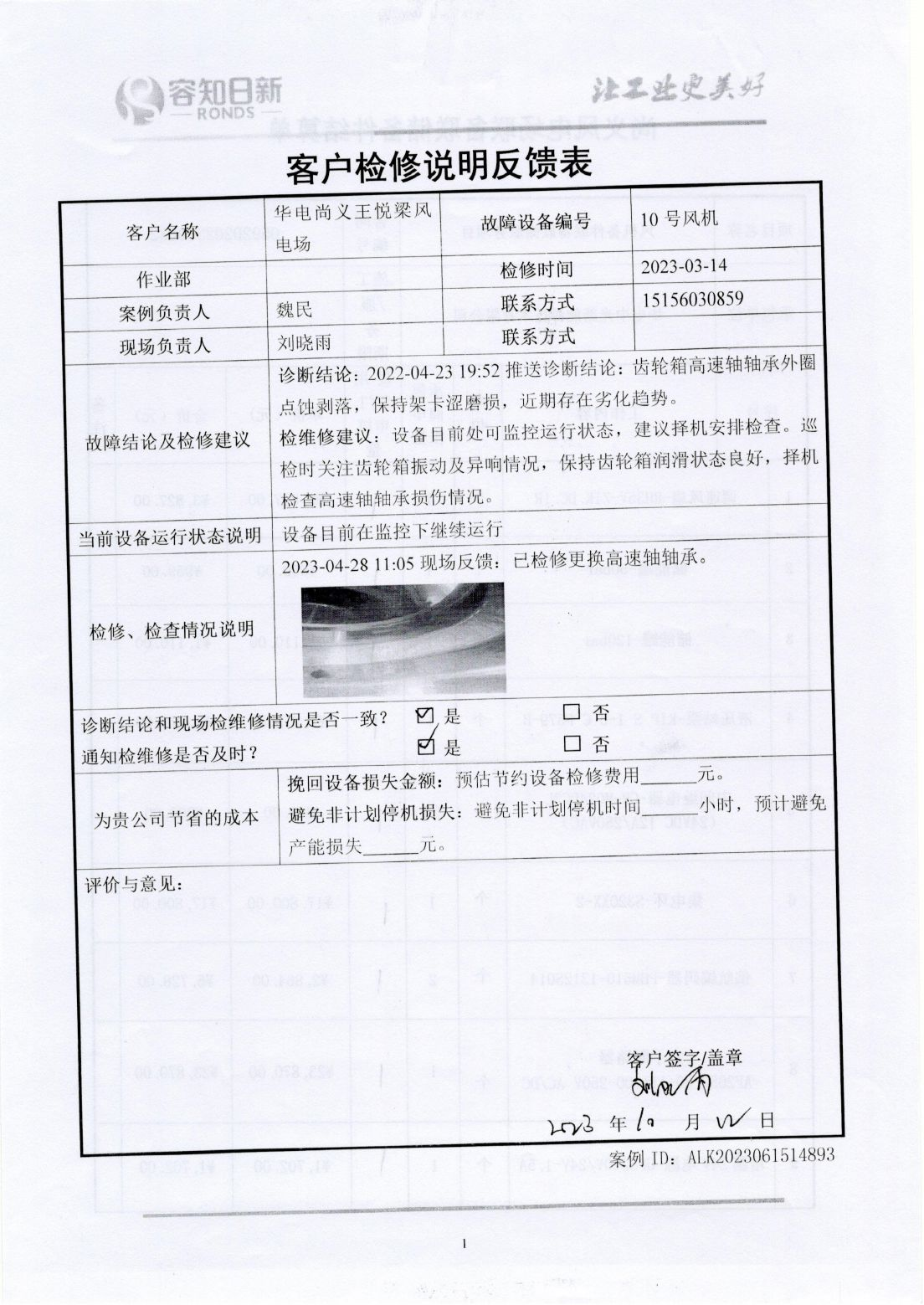

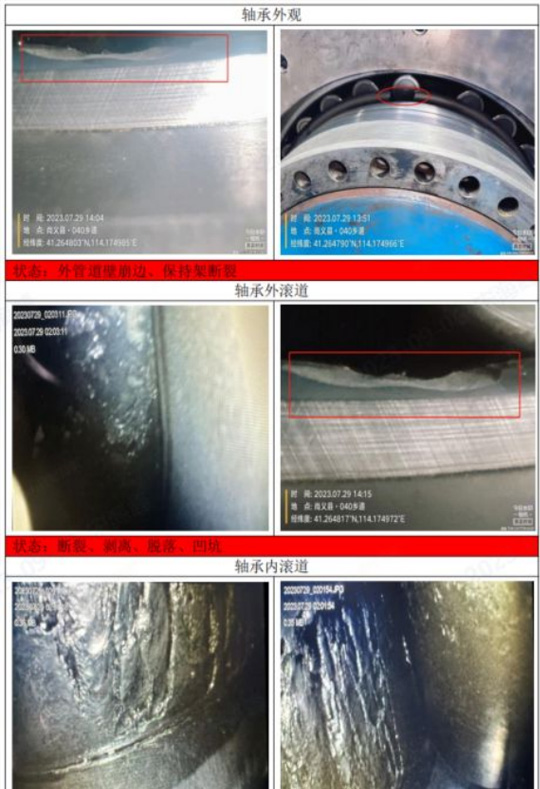

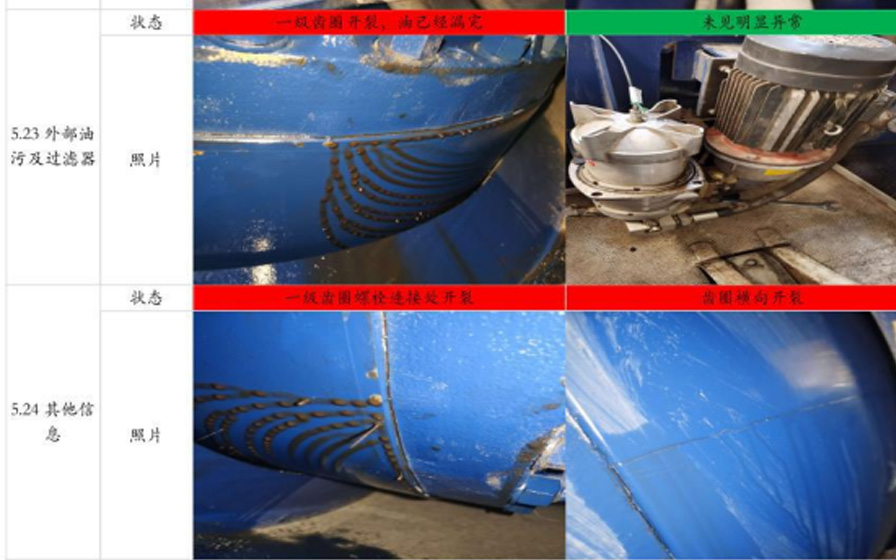

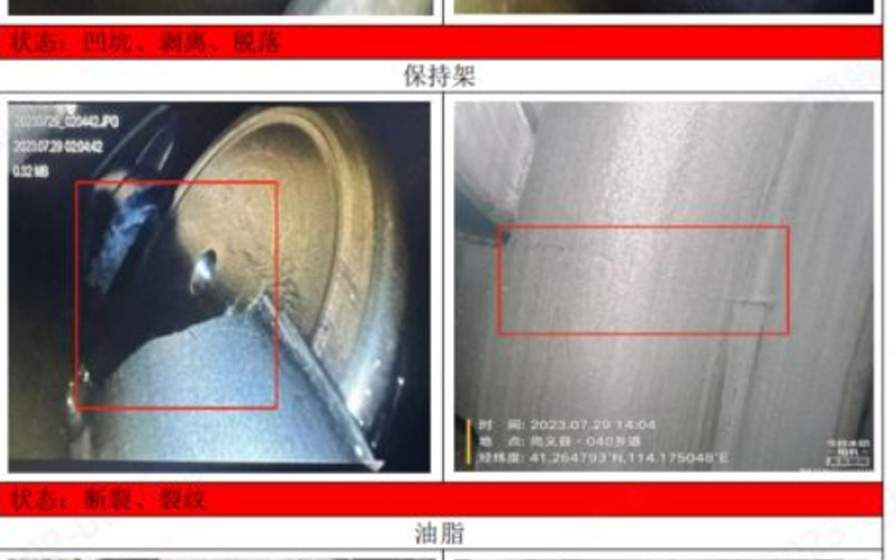

China Huadian Shangyi Wang Yueliang Wind Power Wind Turbine No. 10

China Huadian Shangyi Wang Yueliang Wind Power Wind Turbine No. 10Learn More

-

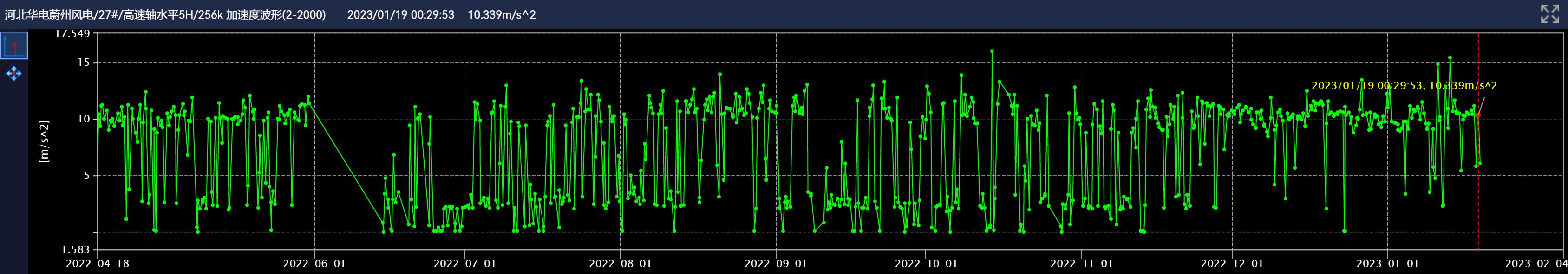

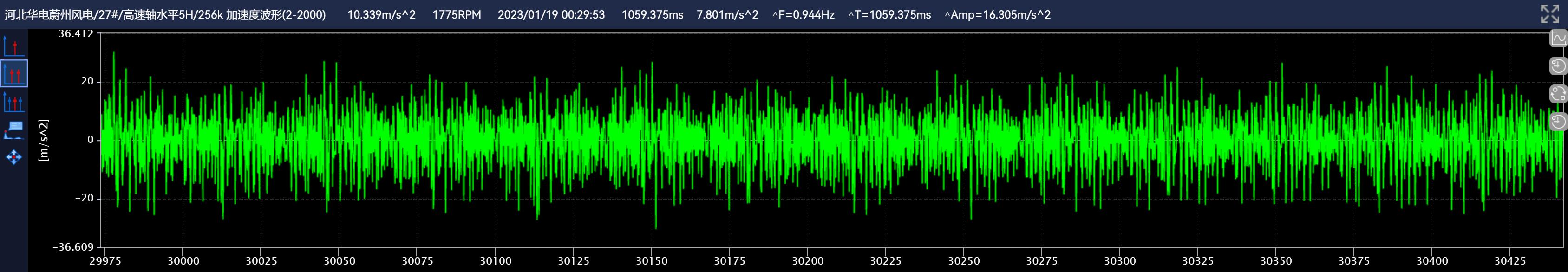

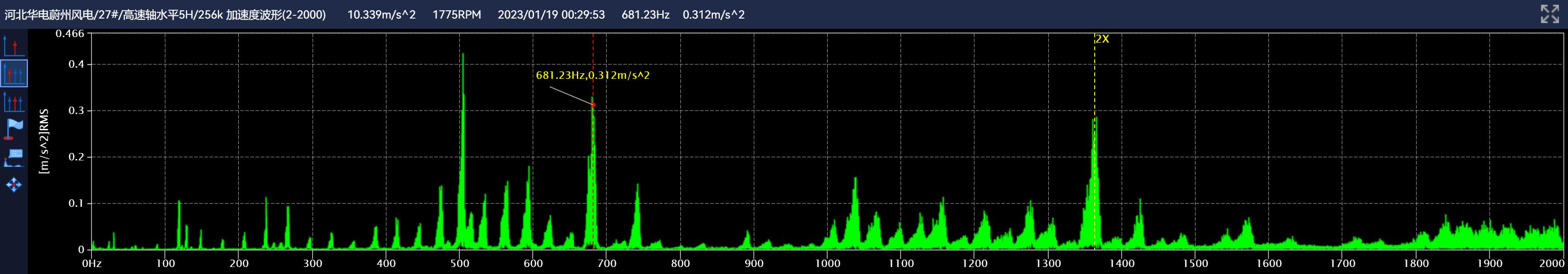

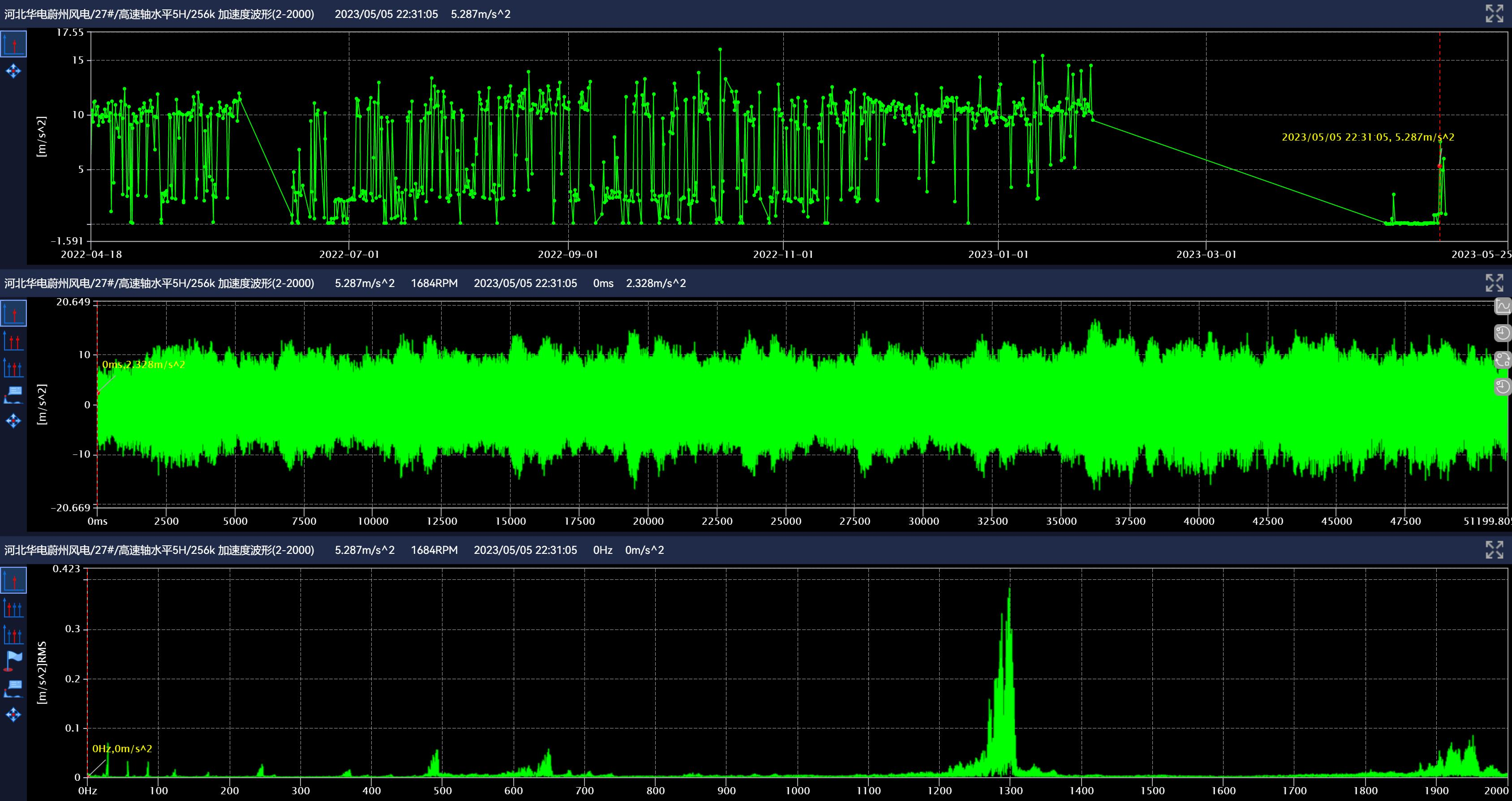

Huate Dian Hebei Weizhou Wind Power Project 27#

Huate Dian Hebei Weizhou Wind Power Project 27#Learn More

-

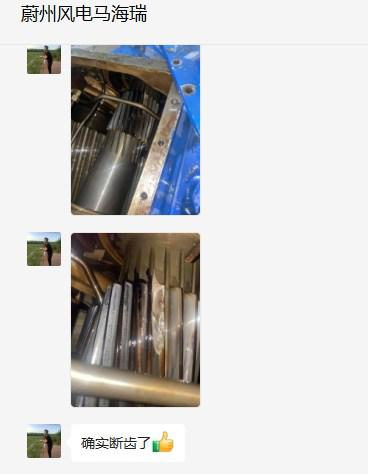

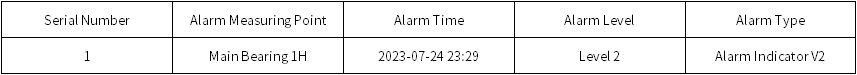

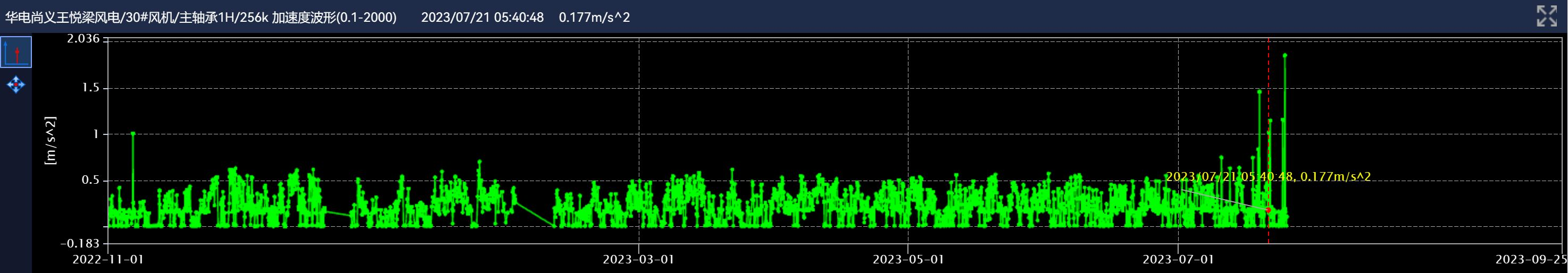

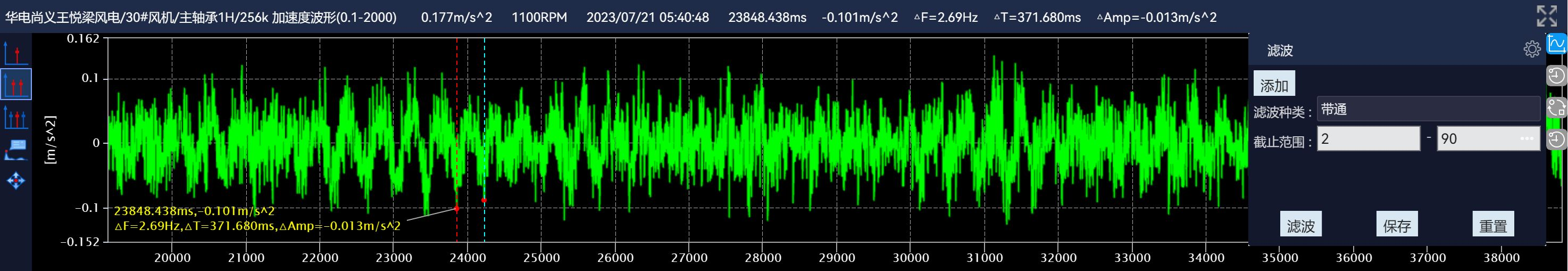

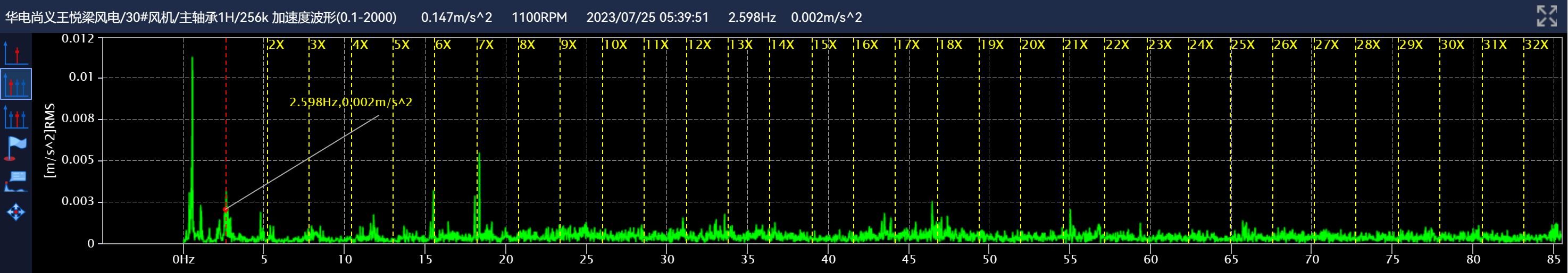

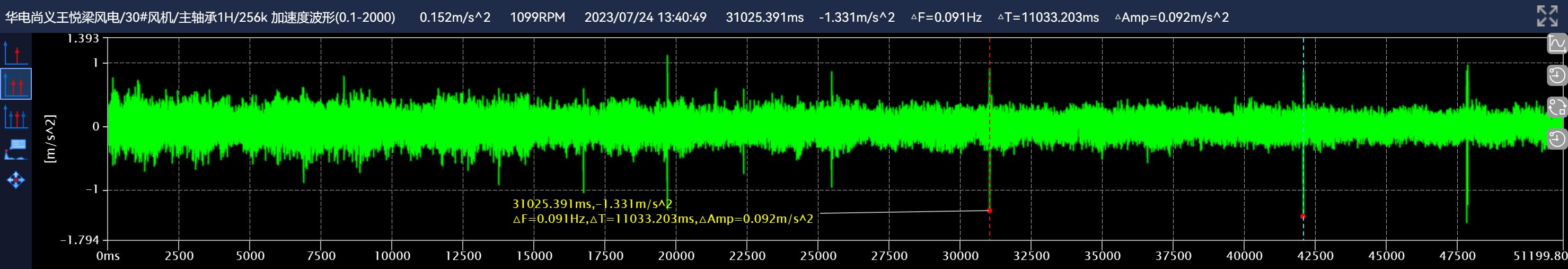

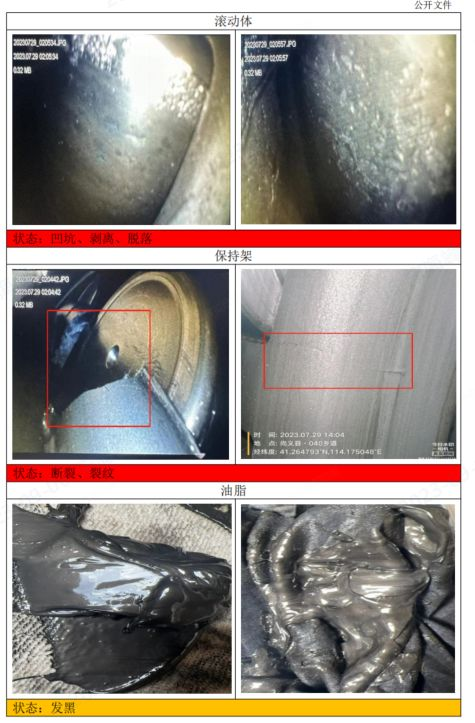

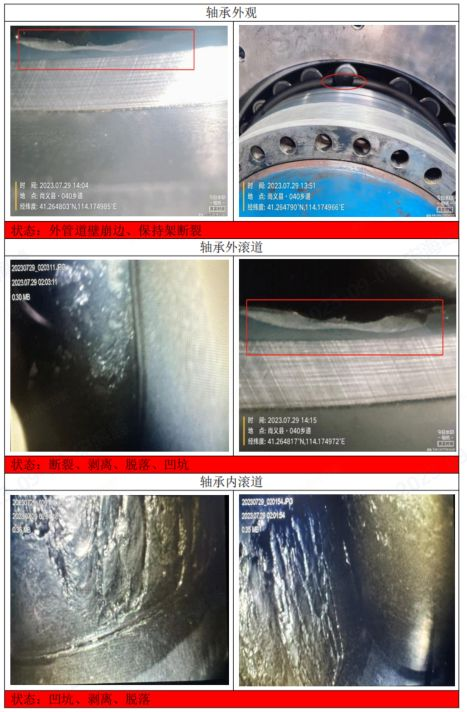

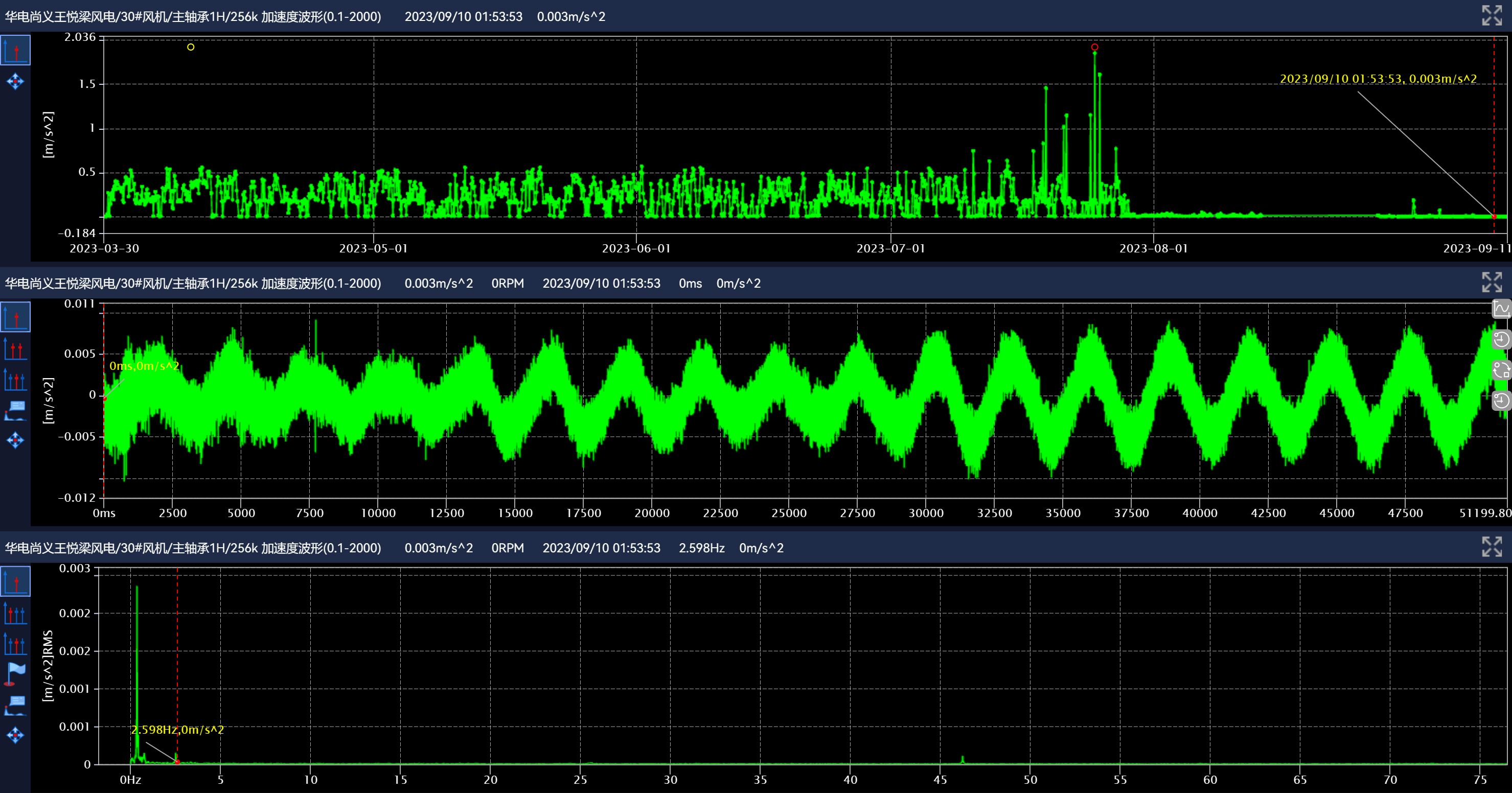

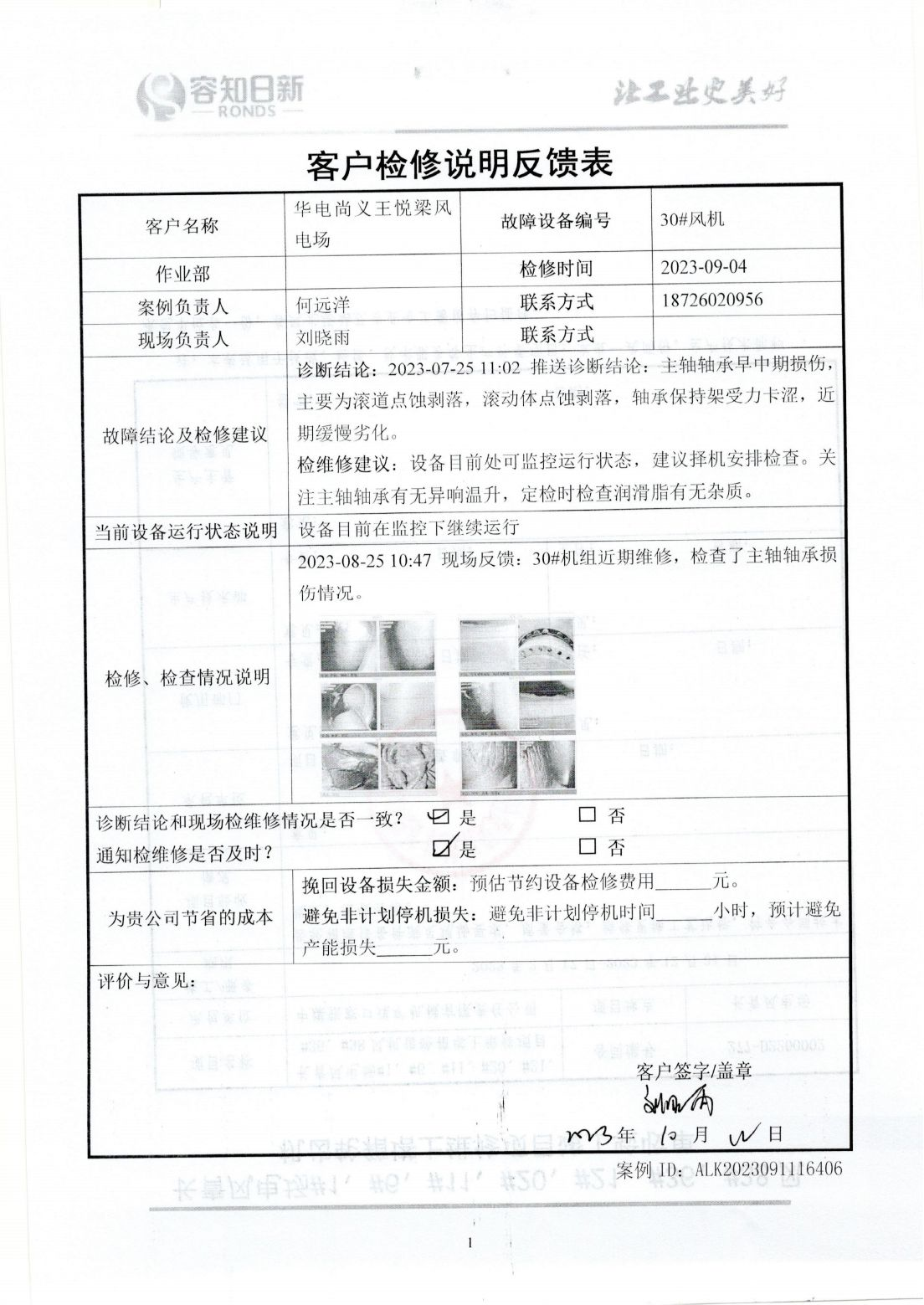

Huate Dian Shangyi Wang Yueliang Wind Farm 30# Wind Turbine

Huate Dian Shangyi Wang Yueliang Wind Farm 30# Wind TurbineLearn More

Start Your Journey to Intelligent Industrial Equipment Maintenance