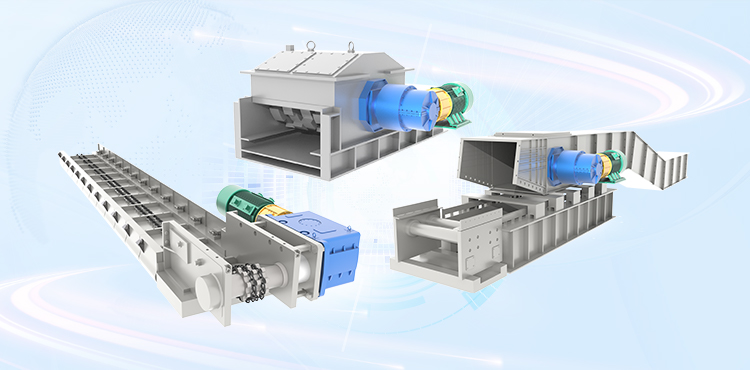

Three Main Coal Mining Machines

The three coal machines, namely the scraper, transfer machine and crusher, are key equipment in underground mines and are related to the overall production capacity. Once an unplanned shutdown occurs, it will lead to huge production losses. The three coal machines have always been accompanied by serious overload operation. In addition, the environment of the comprehensive mining face is complex, and the continuous movement and working conditions change, which makes monitoring extremely difficult. This is a major challenge for equipment operation and maintenance in the coal industry. Ronds's intelligent monitoring solution for the three coal machines can effectively cope with the harsh on-site environment. Through comprehensive monitoring of mechanical failures and oil failures of the three machines, it realizes the transformation of the comprehensive coal mining face from planned maintenance and post-event emergency repairs to status maintenance.

Monitoring Challenges

-

Difficult Wiring

The conditions at the three-machine site were harsh and the wiring solution layout was complex.

-

Many False Positives

The mobile equipment on the working face has complex operating conditions, traditional data collection has many false alarms, and the diagnostic analysis is stressful.

-

Limited Means

It is impossible to achieve wireless monitoring of equipment process quantities, such as liquid level, pressure, temperature, flow, etc.

-

Poor Concealment

Although common wireless sensors on the market have solved the problem of working face wiring, they are large in size and poor in concealment. Sensors often fall off due to excessive vibration and falling coal, and they have weak adaptability.

-

Short Battery life

Common wireless sensors on the market have short battery life and more complicated operation and maintenance management.

Solution Advantages

-

01Split Full Wireless Deployment

Split installation and deployment, the sensor is smaller in size than the integrated one, the installation and deployment is more flexible and concealed, and the reliability is higher under harsh conditions. Targeted sensors are configured according to different parts and different fault types to improve coverage and monitoring accuracy.

-

02Professional Oil Monitoring and Analysis

Utilizing professional oil monitoring and analysis technology, a unified monitoring system is implemented for wear particles, moisture, water activity, dielectric constant, viscosity, and density in the oil of the three machines, further enhancing their operational reliability.

-

03Multi-parameter Collection and Alarm System

Comprehensive performance upgrade, close to the wired monitoring effect, support indicators, super indicators, waveforms, long waveforms and black box collection functions, comprehensively improve the quality of data collection. Based on the unique intelligent collection strategy of the three machines and the intelligent alarm strategy, the edge end is implanted with 100+ characteristic indicators.

-

04Second-Level Working Condition Collection

The working condition sensor realizes data collection and calculation of working conditions in seconds, and intelligently identifies the speed and start and stop status.

-

05365*24h Real-Time Monitoring

Ronds provides 365*24 hours of cloud-based expert support, professional diagnostic services, and advance warnings to help comprehensive mining working faces from planned maintenance, post-event emergency repairs to condition-based maintenance.

Innovative Features

-

Miniaturization

Miniaturized wireless sensors, concealed installation, more flexible, more reliable, and more environmentally adaptable.

01 -

Fewer False Positives

Operating condition fluctuations, correlation analysis, and more accurate diagnosis.

02 -

Ultra-long Battery Life

Wireless sensors have low power consumption, large batteries, and a lifespan of more than 3 years, making them more durable.

03 -

Comprehensive Monitoring

Comprehensive monitoring of vibration temperature + working condition + oil, covering all faults.

04

Start Your Journey to Intelligent Industrial Equipment Maintenance