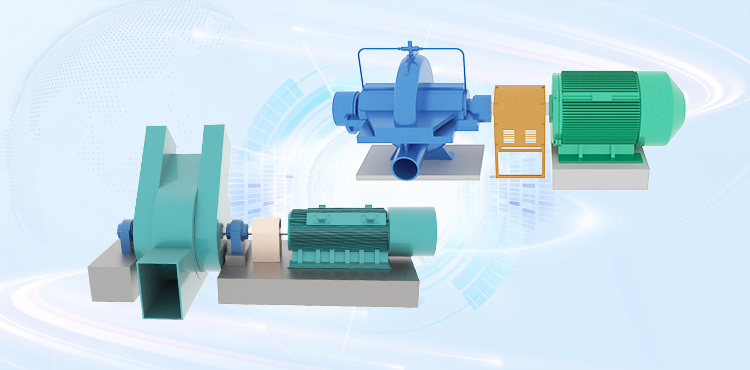

Stable Speed Equipment

Steady-state equipment refers to equipment with relatively stable working conditions, such as various fans, water pumps, and belt equipment in the metallurgical industry. They are commonly found in various production lines in the metallurgical industry, and once these equipment suddenly fail, they may affect the production of the entire production line or cause serious pollution to the environment. Ronds's steady-state equipment intelligent monitoring solution can realize the equipment management mode from post-maintenance and preventive maintenance to predictive maintenance, realize real-time control of equipment status, and safe and continuous production.

Monitoring Challenges

-

Preventive Maintenance

Although it ensures the safe operation of the device to a certain extent, it brings a lot of maintenance work and easily causes "over-repair" or "under-repair" and waste of spare parts.

-

Insufficient Inspection Points

Traditional point inspections can only detect late-stage faults, and rapid degradation and sudden faults are often difficult to detect. In addition, the number of pumps is huge, making daily inspections difficult.

Solution Advantages

-

01Multi-dimensional Monitoring

It integrates the collection of vibration, temperature, and motor working conditions to realize self-identification of temperature, speed, and start and stop. It also realizes accurate alarm and accurate statistics of start and stop duration based on working conditions.

-

02100+Indicators Edge Computing

It can realize accurate pointing alarm at the collection end and improve early warning efficiency.

-

03Abnormal Trigger Collection

Once an abnormality is detected, data is collected immediately and transmitted back with priority to ensure timely response to the fault.

-

0420+ Fault Automatic Monitoring

Intelligent alarm and intelligent diagnosis based on a multi-indicator system, covering automatic monitoring of more than 20 faults such as bearings and power frequency.

-

05Full Wireless Deployment

Flexible networking deployment can be achieved based on on-site conditions.

Start Your Journey to Intelligent Industrial Equipment Maintenance