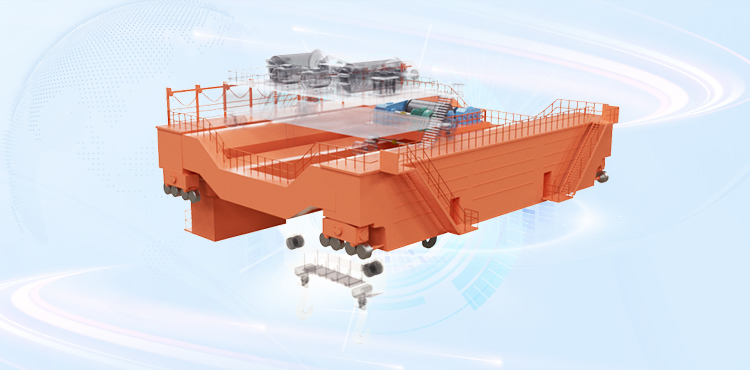

Overhead Cranes

Overhead crane is a bridge crane, which is one of the basic production equipment in the metallurgical industry. It integrates loading and unloading, handling and transportation functions, and is a key factor in determining the efficient operation of production. Due to the long-term non-continuous movement of overhead cranes, special locations, and difficulty in fault detection, there has always been a lack of efficient and reliable operation and maintenance methods. Ronds's intelligent monitoring solution for overhead cranes focuses on the "three highs and three majors" pain points of overhead crane operation and maintenance, as well as the four major monitoring problems of key component failures to achieve a comprehensive breakthrough, so that overhead cranes can be monitored, accurately monitored, easy to implement, and require less maintenance.

Monitoring Challenges

-

High Concealment

Overhead crane failures are highly concealed, difficult to identify during static inspections, and carry high risks during dynamic inspections.

-

High Safety Risk

Metallurgical overhead cranes have heavy loads and frequent operations. The transportation of molten high-temperature metals involves dangerous factors such as high temperature, high risk, and high dust, posing high safety risks.

-

High Regulatory Requirements

Overhead cranes fall under the category of special equipment management, and the market regulatory authorities have high supervision requirements, which is a great test for the staff.

-

Difficulty in Inspection

Overhead cranes have a special operating environment, with high and narrow walking passages and other moving equipment in the middle. As a result, they take a long time to move around, have a short effective inspection time, and are difficult to inspect.

-

Failure Has a Great Impact

In the management of overhead cranes on multiple production lines, responsive maintenance can easily cause unplanned downtime and safety accidents, and the impact of failures is great.

-

Huge Workload

It is unable to provide guidance on equipment fault diagnosis and maintenance, and can only replace and overhaul equipment regularly, which results in a huge workload and is accompanied by excessive maintenance waste.

Solution Advantages

-

01Wide Range of Monitoring

The monitoring covers many objects such as the trolley mechanism, car mechanism, lifting mechanism, electrical room, etc., and can realize temperature and humidity integration, PLC access, etc., with a very wide range.

-

02Multi-dimensional Monitoring Capabilities

It can realize monitoring in multiple dimensions such as vibration, impact, noise, working conditions, etc., and has more powerful intelligent algorithms to more comprehensively understand and judge the real-time status of the overhead crane.

-

0324/7 Care

Ronds provides 365*24 hours cloud-based expert support and can provide professional diagnostic services.

-

04Intelligent System Support

Relying on Lingzhi SuperCare Equipment Intelligent Operation and Maintenance Platform 2.0, an intelligent monitoring system for overhead cranes is created. It can be applied on both mobile phones and computers. It is flexible and convenient. It also has intelligent and complete alarm processing and fault linkage processing functions.

-

05Efficient Operation and Maintenance Management

In addition to real-time status monitoring, it can also provide regular inspection reminders, archive inspection reports, etc., to help upgrade on-site special equipment management, making management easier and more efficient.

-

06Fast Construction Delivery

The construction time for wireless deployment is extremely short and can be covered by the regular downtime of the factory line, enabling rapid construction delivery.

Start Your Journey to Intelligent Industrial Equipment Maintenance