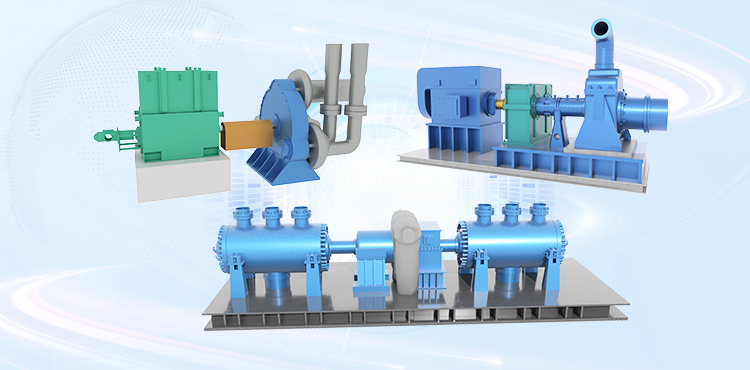

Large Petrochemical Units

Ronds deploys a specialized Data Collector system for large units such as propylene compressors, synthesis gas compressors, circulating gas compressors, and booster compressors. This system re-samples and analyzes operating data (e.g., vibration acceleration and shaft displacement) from the safety protection system. By also incorporating relevant process parameters, it provides early warnings for equipment anomalies, conducts diagnostic analysis, and locates faults. This enables proactive identification of abnormal conditions, guiding maintenance personnel to take timely measures, preventing sudden failures, and reducing unplanned downtime.

Monitoring Pain Points

-

High Volume and Complexity of Data

Large units typically include numerous sensors and monitoring points, generating vast and complex data—covering vibration, temperature, pressure, flow, and more—that must be effectively processed and analyzed.

-

Diverse Fault Characteristics

Multiple types of faults may occur in large units, potentially overlapping in ways that make them difficult to identify and analyze accurately, requiring a comprehensive approach.

-

Long-Term Monitoring and Forecasting

Large units often require long-term condition monitoring and forecasting, taking into account aging, wear, and environmental changes. Accurately predicting equipment status over the long term can be challenging.

-

Data Quality and Reliability

The quality and reliability of monitoring data are crucial for condition monitoring, including accuracy in Data Collector, sensor stability, and reliability of data transmission.

-

Multi-Variable Correlation Analysis

Monitoring large units necessitates understanding correlations among multiple variables, requiring complex multivariate analysis and modeling.

Solution Advantages

-

01High Accuracy in Data Collector

Employing Ronds’ patented full-sampling technology, designed for the operational characteristics of large units, enables multi-channel synchronous and real-time data collection. With an analysis frequency of up to 51.2 kHz, it can calculate FFT with up to 12,800 lines. The system’s dynamic range exceeds 110 dB, ensuring accurate collection of signals at the millivolt level.

-

02Strong Diagnostic Team

Ronds has a professional and highly capable diagnostic team that accurately determines the extent, cause, and location of equipment faults, offers maintenance recommendations, and provides life expectancy assessments. This approach avoids premature component replacement, reduces repetitive costs and the lead time for critical spare parts, and mitigates losses from unplanned downtime.

-

03Excellent Scalability

The system supports various communication methods—Ethernet, optical fiber, and RS485—to adapt to different site requirements.

Start Your Journey to Intelligent Industrial Equipment Maintenance