Gearbox Lubricating Oil

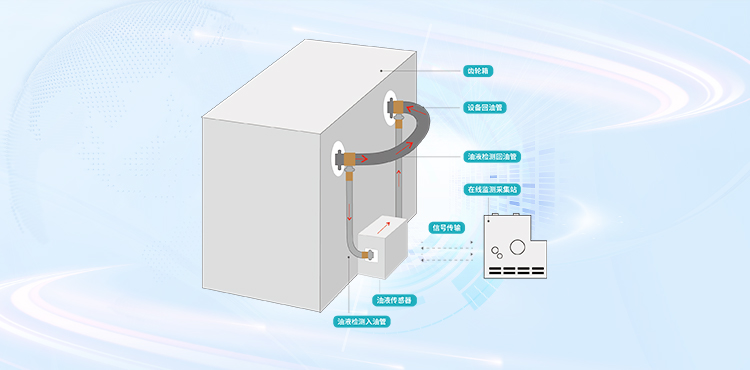

Ronds' intelligent monitoring solution for gearbox lubricating oil continuously monitors changes in oil quality and the generation of abrasive particles through online monitoring technology, and detects early faults such as poor lubrication of the gearbox. Through data analysis and diagnosis, it guides on-site personnel to make equipment maintenance decisions, and realizes predictive maintenance and visualization of oil status, real-time display, and indicator trend analysis.

Monitoring Challenges

-

Laboratory Analysis

The transmission and analysis time is long and the timeliness is poor; the sampling process may cause secondary contamination to the oil; the data presentation form is weak.

-

Field testing

It is necessary to purchase professional equipment and add professional testing personnel, which increases costs and management difficulties; the deep-seated causes of equipment failures behind the oil status cannot be analyzed.

Solution Advantages

-

01Accurate Monitoring

Strong power can reduce system pressure loss, more complete oil sampling and more accurate detection results.

-

02Indicator Visualization

It can detect key parameters such as metal wear particles, moisture, viscosity, temperature, density, dielectric constant, etc. in the oil, visualize the data, and comprehensively display the multi-dimensional monitoring index card.

-

03Unified Management

It can be connected to the predictive maintenance system and supports the access of various process data of equipment to comprehensively evaluate the equipment status.

Multi-dimensional Monitoring

-

Wear Particle Analysis

The composition, content and size of solid particles in oil samples are analyzed by the principle of electromagnetic induction to explore the wear mechanism, wear location and cause of wear of the equipment and predict the wear development trend.

01 -

Moisture Analysis

The principle of polymer humidity-sensitive capacitor is used to detect the water content in oil. The water in the oil will reduce the strength of the oil film, cause emulsification and deterioration, and cause pitting corrosion of the equipment.

02 -

Dielectric Constant Analysis

The ceramic interdigital electrode principle is used to detect the dielectric constant value. Continuous monitoring can reveal the wear trend of the friction pair of the components and the consumption of lubricant additives.

03 -

Viscosity Analysis

The resonance principle is used to monitor viscosity changes. The thickness of the lubricating oil film is directly related to the viscosity, and the thickness of the oil film determines the degree of wear between the friction pairs.

04

Start Your Journey to Intelligent Industrial Equipment Maintenance