Scenario-based intelligent solutions

Ronds, based on our understanding of the industry and scenario-based algorithm capabilities, addresses various industrial site challenges by building multiple scenario-based intelligent operation and maintenance applications. These solutions are designed with the ability to expand continuously in the future, creating unlimited possibilities and ensuring reliable equipment operation!

-

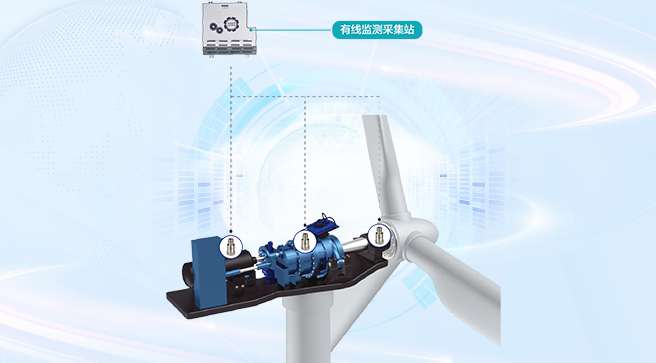

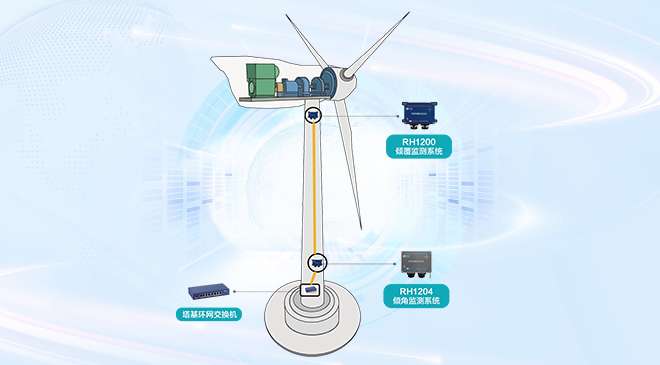

Wind Turbine Transmission Chains

Wind Turbine Transmission ChainsRonds 's wind turbine transmission chains intelligent monitoring solution uses intelligent acceleration sensors to collect vibration data from main bearings, gearboxes, generators and other parts to monitor the operating status of equipment. Through fault diagnosis technology, it evaluates the status of major components of the transmission chain, locates the root cause of the fault, predicts the remaining life of the components, and realizes control of the equipment status.

Learn More

-

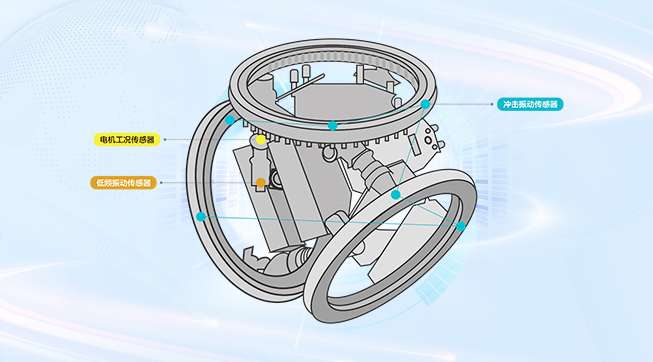

Pitch Bearings

Pitch BearingsRonds 's intelligent monitoring solution for variable pitch bearings effectively solves the three major maintenance pain points and three major monitoring problems of wind turbine variable pitch bearings.

Learn More

-

Wind Turbine Bolt

Wind Turbine Bolt Ronds ' intelligent bolt monitoring solution collects real-time data on the gap displacement of bolt connection flange surfaces and bolt preload force to determine the operating status of bolts, avoid major damage to the unit and damage to power generation caused by bolt loosening and breakage, and provide data support for the safety and reliability of wind turbine operation, ensuring that operation and maintenance personnel can grasp the real-time status of bolt operation in real time and accurately, thereby improving management level.

Learn More

-

Wind Turbine Tower Vibration and Foundation Settlement

Wind Turbine Tower Vibration and Foundation SettlementRonds's tower sway and foundation settlement intelligent monitoring solution collects tower sway inclination, vibration, gyroscope and other data through an intelligent monitoring system to understand the health status of the tower, detect early faults, avoid sudden failures, reduce unplanned downtime, and assist companies in formulating reasonable inspection and maintenance plans to avoid tower collapse and major safety accidents.

Learn More

-

Wind Turbine Blade

Wind Turbine BladeRonds' intelligent blade monitoring solution uses intelligent monitoring sensors to collect data such as blade vibration, temperature, and load. It uses intelligent algorithms combined with the operating status of the wind turbine to conduct comprehensive analysis and predict potential blade failures, make early warning analysis of the blades, and achieve blade status assessment and fault diagnosis, providing services for maintenance and management decisions of blade equipment.

Learn More

-

Thermal Power Main and Auxiliary Equipment

Thermal Power Main and Auxiliary EquipmentUse smart sensors to reduce reliance on manual labor, use sensors and rules to replace or reduce the daily equipment inspection load on site, and improve labor efficiency.

Learn More

Start Your Journey to Intelligent Industrial Equipment Maintenance