Wind Turbine Bolt

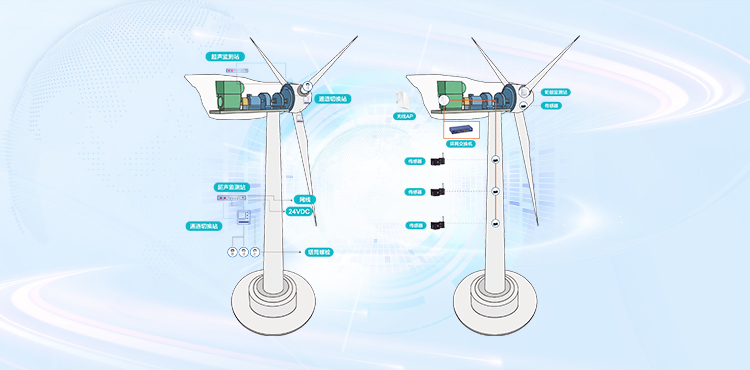

Ronds' intelligent bolt monitoring solution collects real-time data on the gap displacement of bolt connection flange surfaces and bolt preload force to determine the operating status of bolts, avoid major damage to the unit and damage to power generation due to loosening and breaking of bolts, and provide data support for the safety and reliability of wind turbine operation, ensuring that operation and maintenance personnel can grasp the real-time status of bolt operation in real time and accurately, thereby improving management level.

Monitoring Challenges

-

Failures Are Prone to Occur

As some flange bolts of wind turbine towers, blades, pitch bearings, etc. are subjected to a series of complex and variable loads, the bolt preload will be reduced, and there is a risk of the bolts loosening, falling off, or breaking.

-

Lack of Reliability

Domestic towers are getting taller and blades are getting longer, but the bolt technology and reliability of key joints have not been fully improved. Especially the root bolts, the bolt failure rate is gradually increasing.

Solution Advantages

-

01Dual Monitoring Strategy

The intelligent bolt monitoring solution uses a rich portfolio of bolt products to create exclusive monitoring strategies for preload force and regional clearance.

-

02Non-destructive Monitoring

Non-destructive processing, no damage to the strength of the bolts.

-

03High Measurement Accuracy

Ultrasonic monitoring uses the principle of acoustic elasticity and can monitor the tiny deformation of the entire bolt material caused by the tightening force. The technology is mature and the measurement accuracy is high.

-

04High Temperature Adaptability

It has the function of temperature Collection compensation, which can offset the accuracy distortion caused by thermal expansion and contraction due to changes in ambient temperature, and achieve better care effects.

Start Your Journey to Intelligent Industrial Equipment Maintenance