Pitch Bearings

The pitch bearing is a critical component in the control system of large-scale wind turbines. It adjusts blade angles to regulate rotor speed and, consequently, the turbine’s power output. Additionally, it enables aerodynamic braking to ensure safe shutdown under emergency conditions. Failures in the pitch bearing can lead to extended downtime for replacement or, in severe cases, catastrophic blade imbalance and detachment. Therefore, implementing early-stage, online condition monitoring of pitch bearings is essential. Ronds' intelligent pitch bearing monitoring solution effectively addresses three core O&M challenges and overcomes three key technical difficulties associated with pitch bearing monitoring in wind turbines.

Monitoring Challenges

-

Wear and Fatigue Failures Occur from Time to Time

Pitch bearings are subject to alternating multi-source loads and work in a harsh environment, so wear and fatigue failure problems often occur.

-

High Maintenance Difficulty

The working environment of pitch bearings is complex and difficult to inspect and maintain. Traditional manual inspection and maintenance methods are inefficient and have delays.

-

Failure Has a Great Impact

It is difficult to detect early crack faults with the naked eye during manual inspection. If early cracks and other faults are not effectively identified and handled, the faults may become serious and cause the blades to become unbalanced and fall, resulting in huge safety and economic losses.

-

Difficulty in Obtaining Fault Signals

The early fault signals of online monitoring of variable pitch are weak, difficult to capture by conventional vibration monitoring methods, and difficult to obtain fault signals.

-

Difficult to Identify Overall Status

Traditional monitoring cannot accurately judge the pitch status of wind turbines, cannot effectively locate pitch failures, and has difficulty identifying the overall status.

-

Collection Signal Analysis Is Difficult

At low speeds, impacts from defects and pitch bearing components have low energy emissions, which are difficult to distinguish from noise and difficult to collect and analyze signals.

Solution Advantages

-

01Efficient Identification

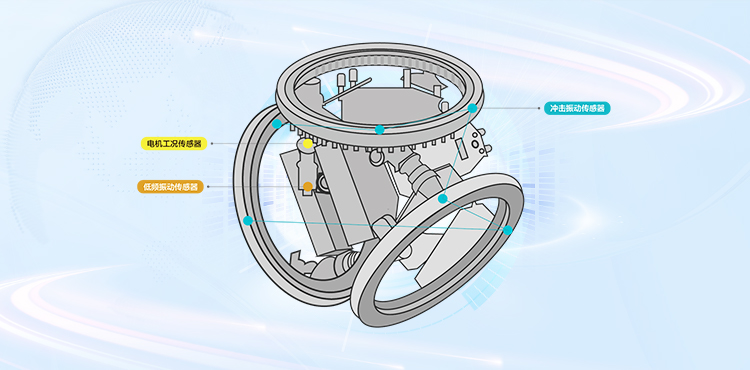

The unique motor operating condition + low-frequency vibration solution identifies the pitch change trigger and accurately grasps the wind turbine pitch change status.

-

02Accurate Diagnosis

Innovative impact vibration monitoring technology combines impact pulse and vibration monitoring to identify and judge early faults of pitch bearings. The dual sensor installation design can more accurately locate damage and improve the effectiveness of alarm and diagnosis.

-

03Fighting Interference

It has the function of locating the impact from the same fault point, has the ability to suppress the running noise, and can effectively eliminate the interference of external impact; it uses indicators such as bearing lubrication, impact size, and impact energy to accurately determine the bearing status.

-

04Integrated Monitoring

Intelligent pitch control monitoring is integrated with blade vibration monitoring and blade root bolt clearance monitoring to achieve integrated monitoring of large blade components.

-

05Intelligent Processing

Based on the SuperCare equipment intelligent operation and maintenance platform, an intelligent monitoring system for variable pitch bearings is created, which has intelligent and complete alarm processing and fault linkage processing functions, refines the alarm process and feedback, and effectively realizes efficient department linkage, rapid fault processing, and timely fault closure.

-

06Expert Support

Ronds provides 365*24 hours cloud-based expert support and can provide professional diagnostic services.

Start Your Journey to Intelligent Industrial Equipment Maintenance