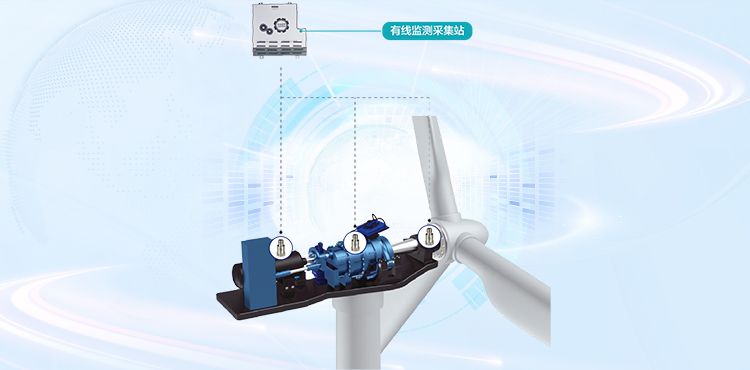

Wind Turbine Transmission Chains

Ronds 's wind turbine transmission chains intelligent monitoring solution uses intelligent acceleration sensors to collect vibration data from main bearings, gearboxes, generators and other parts to monitor the operating status of equipment. Through fault diagnosis technology, it evaluates the status of major components of the transmission chain, locates the root cause of the fault, predicts the remaining life of the components, and realizes control of the equipment status.

Monitoring Challenges

-

Large Amount of Inspection and Maintenance Work

During the operation of a wind turbine, it is difficult to detect faults during routine inspections of bearings and gearboxes, and the inspection and maintenance workload is large.

-

Failure Has a Great Impact

Failure of key mechanical components such as the main shaft, generator, and gearbox causes abnormal shutdown of the unit, seriously reduces power generation efficiency, and increases inspection and maintenance costs.

Solution Advantages

-

01Multi-dimensional Real-Time Collection

Supports real-time synchronous Collection of acceleration and rotation speed signals.

-

02Authoritative Certification Guarantee

The data collector has CE and GL certifications, and its hardware is mature and stable for online monitoring of wind power sites.

-

03Quickly Discover Hidden Dangers

Intelligent alarm + auxiliary diagnosis to detect hidden dangers at the first time.

-

04Outstanding Nursing Ability

Data collector is of higher quality, with strong monitoring capabilities for complex components such as the low-speed stage and gearbox.

-

05Professional Diagnostic Support

Supported by powerful and professional diagnostic capabilities, it has advantages in low-speed critical and difficult fault care.

Start Your Journey to Intelligent Industrial Equipment Maintenance